Detection method and device for bottom thread of computer embroidering machine

A thread detection and computer technology is applied in the field of bottom thread detection of computerized embroidery machines, which can solve the problems of inability to distinguish bottom thread and upper thread breakage, inability to detect bottom thread breakage, and high processing cost of bobbins, achieving simple structure and easy adjustment. , The effect of low cost of electronic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

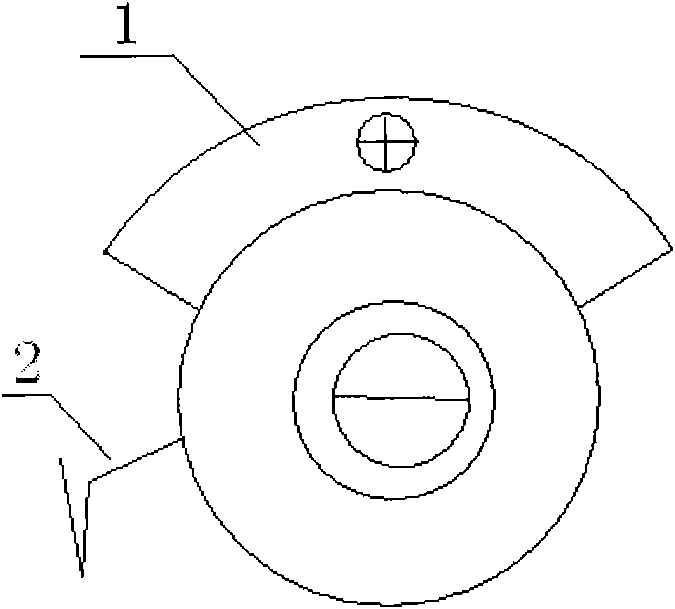

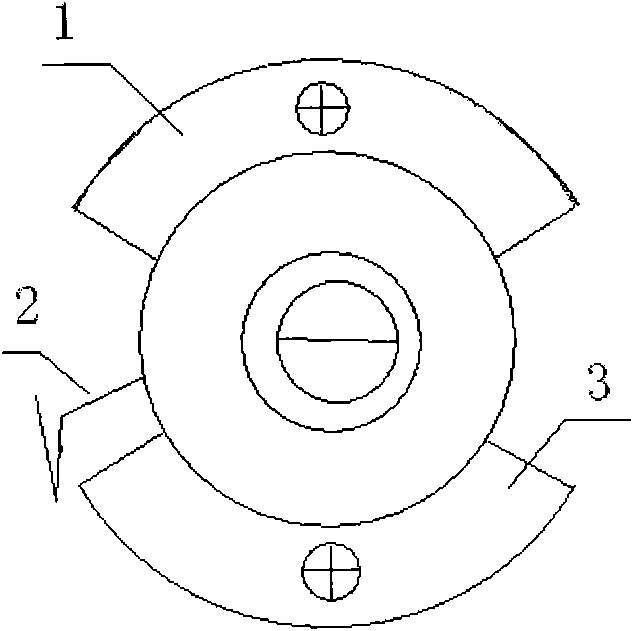

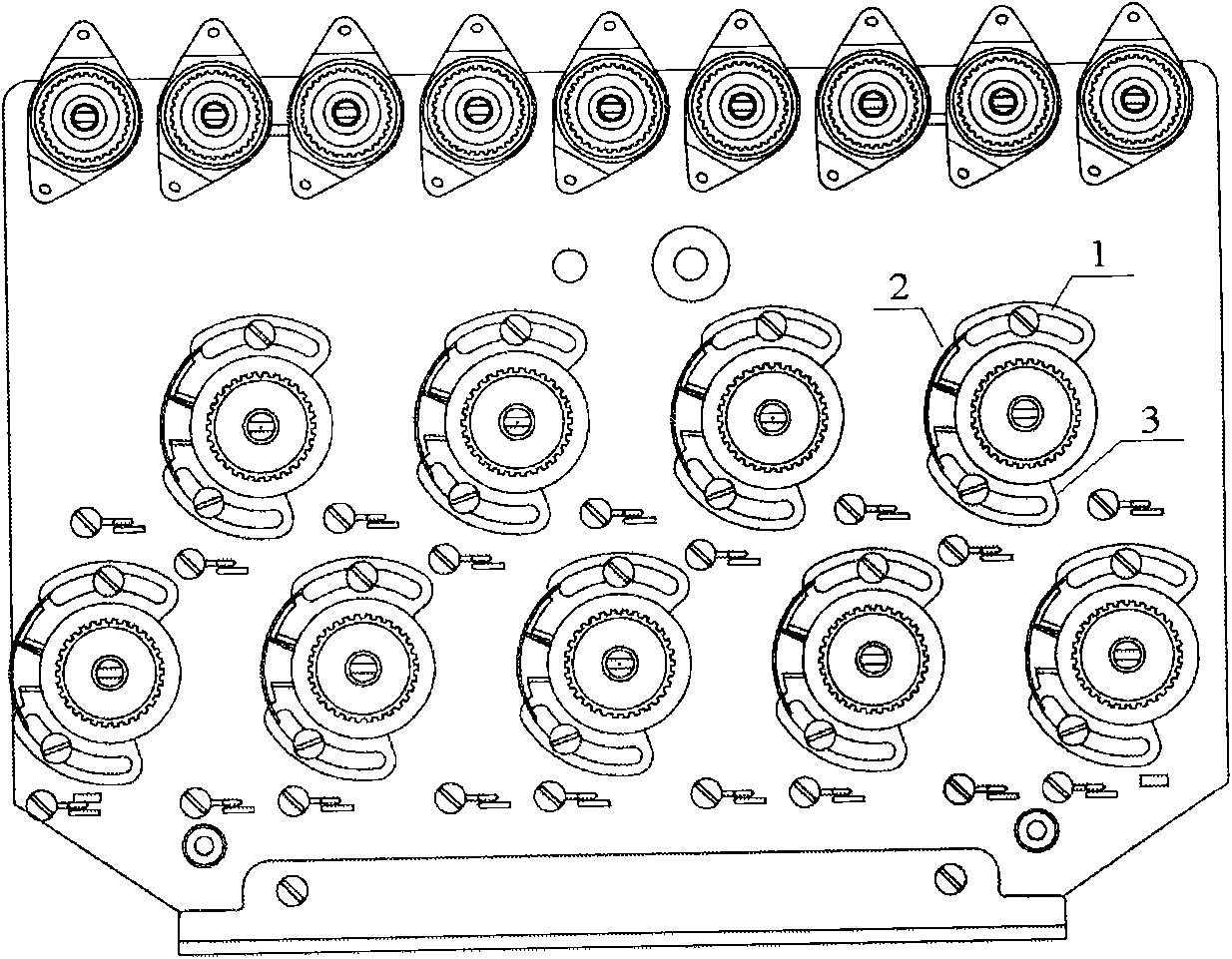

[0027] This example is a nine-needle thread clamping seat. A side thread detection contact 1 is provided above the movement track of the metal thread take-up spring 2 of each thread clamping seat, and a bottom thread detection contact 3 is provided below. Both contacts are metal copper. The column is movably embedded in the circumferential arc-shaped sliding groove, and is relatively fixed with the sliding groove through an adjusting screw, and the positions of the two detection contacts can be adjusted through the adjusting screw.

[0028] When the thread take-up spring is released and reset to the top by the upper thread, it can touch the upper thread detection contact 1, and when the movement range reaches the maximum, it can touch the bottom thread detection contact 3 below.

[0029] The front and back sides of the two detection contacts are conductive, the wire take-up spring is in contact with the front part of the contact, the rear part of the contact is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com