Safety device of mini-type punching equipment

A technology of stamping equipment and safety devices, applied in the field of safety devices of small stamping equipment, can solve the problems of affecting work efficiency, high machining accuracy of structural parts, labor- and time-consuming adjustment, etc. easy-to-create effects

Active Publication Date: 2011-01-05

苏州托克斯冲压设备有限公司

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The applicant has developed an invention patent with application number 200810019940.X "Safety Device for Small Stand-alone Stamping Equipment", which discloses a safety device, which uses a gas-hydraulic booster cylinder, air cylinder, hydraulic cylinder Supporting use of small stand-alone stamping equipment multi-safety safety protection device, including safety distance detection function device, resistance buffer detection function device, insulation or conduction detection function device, safety impact force pressure regulating device, resistance buffer detection function device and safety impact The pressure regulating device can be combined with the safety distance detection function device and the insulation or conductivity detection function device to form a double insurance safety protection system device, but this safety device still has the following shortcomings: 1. The system is complex and the structural parts are manufactured with high precision High cost; 2. The mechanical and electrical control needs to be adjusted synchronously, which is difficult, and the adjustment is labor-intensive and time-consuming. It is difficult for the operator to master and affect the operation efficiency; 3. The adjusted safety distance can only be adapted to mass production, not suitable for variable small-batch production; 4. The adjustment requires enough buffer distance between the machinery and the electric control to ensure the transmission of the signal. Only at the cost of sacrificing the working cycle and reducing the working efficiency, the operating cost is increased.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

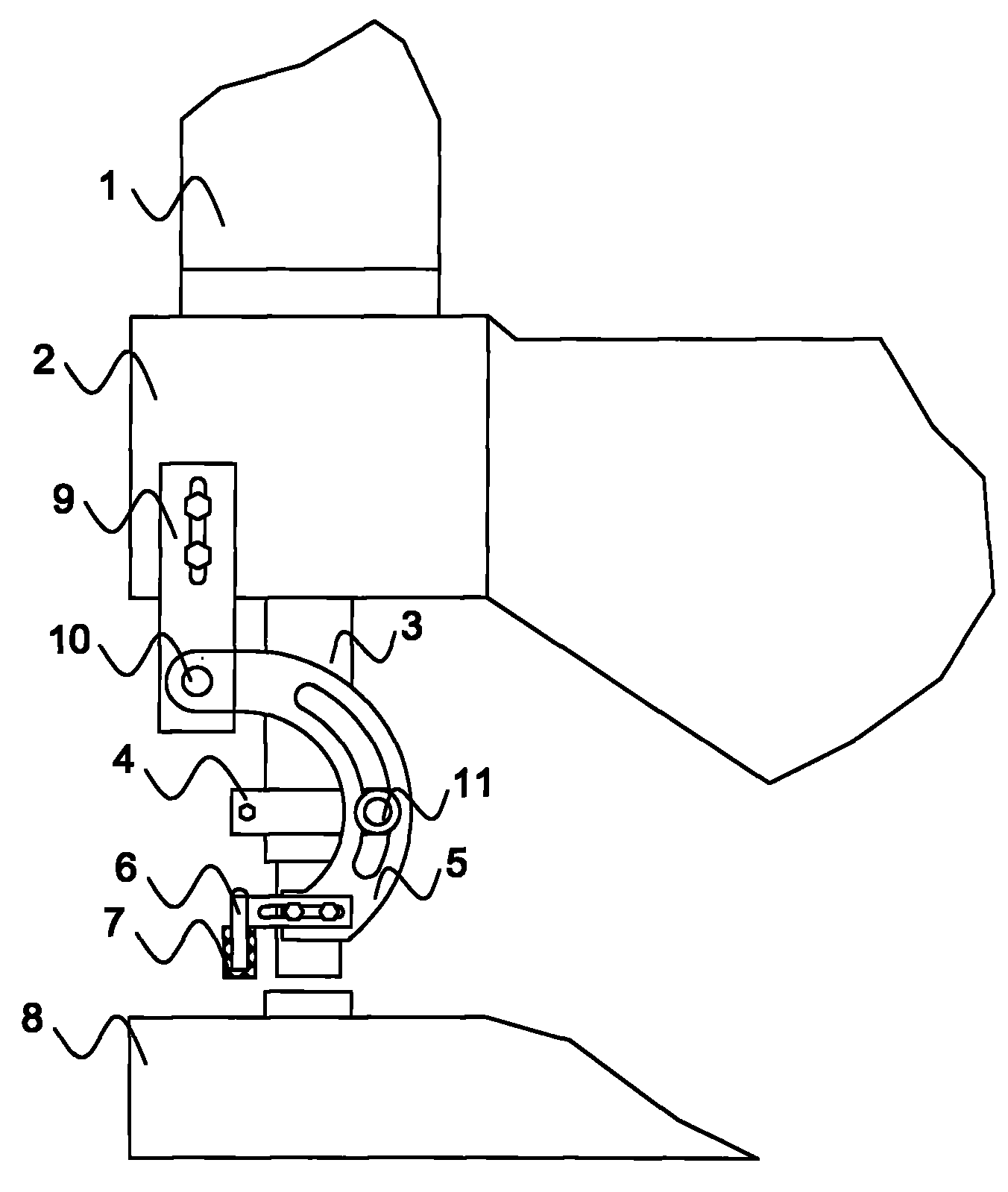

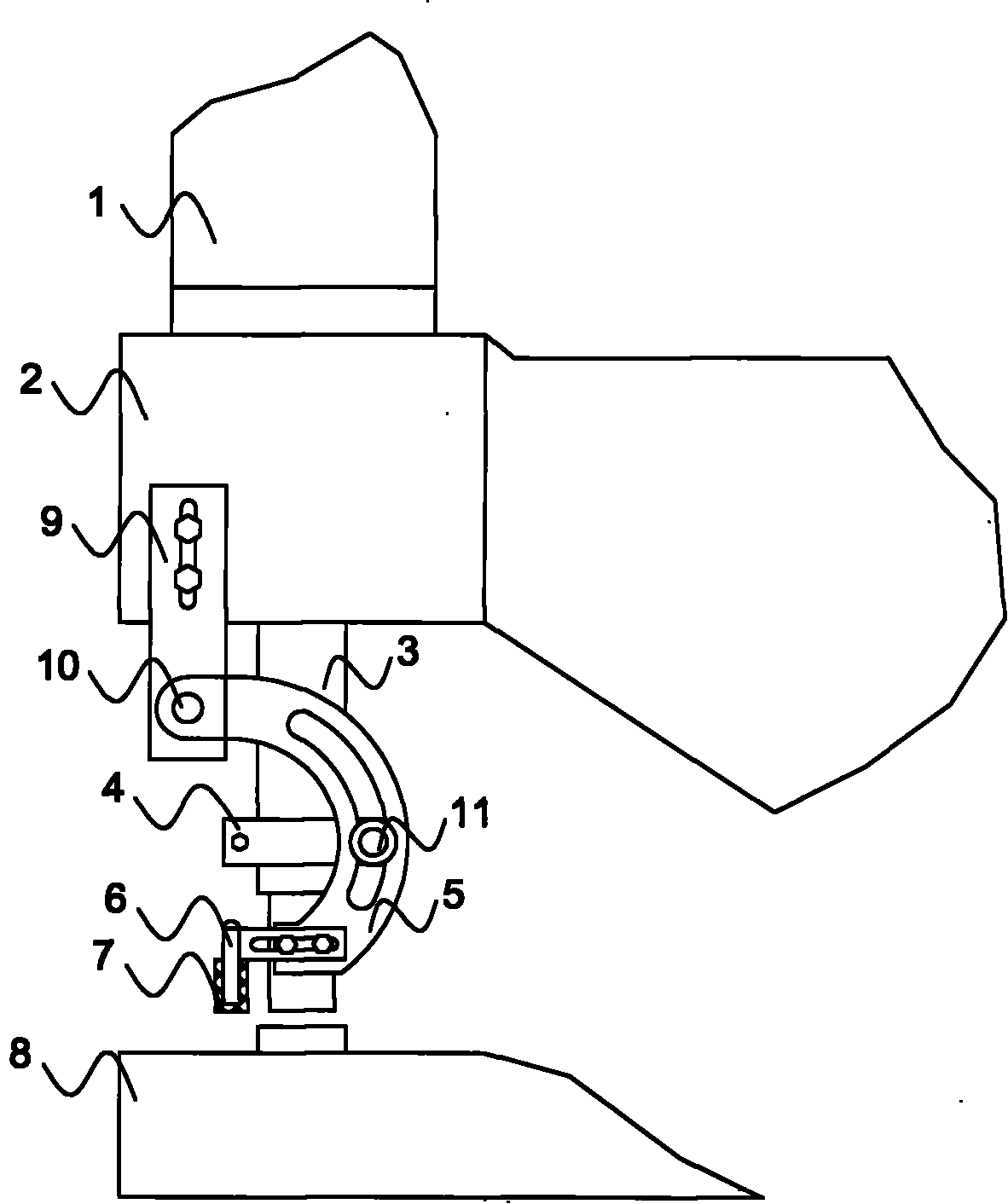

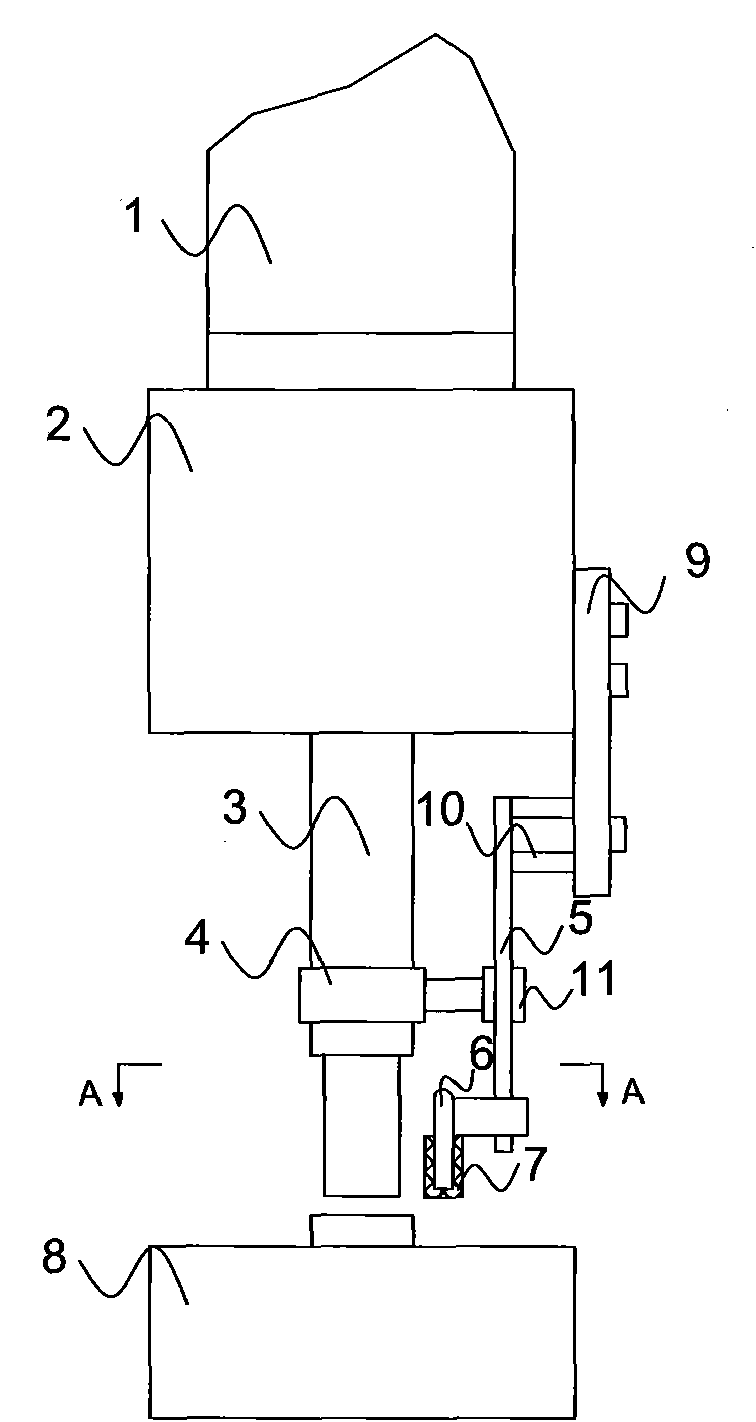

Login to View More Abstract

The invention discloses a safety device of mini-type punching equipment, which is used for mini-type punching equipment. The safety device of the mini-type punching equipment comprises a switching block, a groove pulley, a curved groove type sliding curved rod and a stop block, wherein the switching block is arranged at the output end of the piston rod of the mini-type punching equipment; the groove pulley can be rotatablely arranged on the switching block; one end of the curved groove type sliding curved rod is rotatablely connected with the machine body of the mini-type punching equipment; the stop block is fixedly arranged on the other end of the curved groove type sliding curved rod; and the groove pulley is installed in the curved groove of the curved groove type sliding curved rod. The invention solves problems in the prior art and provides the safety device of the mini-type punching equipment, which has the advantages of simple structure, economy, practicality, convenience, flexibility, stability and reliability, is suitable for batch production and does not disturb normal processing operation.

Description

Small stamping equipment safety device technical field The invention relates to a safety device, in particular to a safety device for small stamping equipment. Background technique At present, the simple manual operation method is still inseparable in the stamping processing industry, that is, the parts are directly taken and placed between the upper and lower molds by hand, especially when picking and placing small workpieces with fingers, there is almost a gap between the fingers and the mold. Zero-distance contact, such stamping equipment without safety protection devices is prone to hand injury accidents. Therefore, how stamping equipment can get rid of frequent finger injuries and severe finger injury accidents caused by operators due to operating errors has always plagued the stamping processing industry. There is a mechanical protection device on the stamping equipment, which is a mechanical protection device that can push a part of the limb away from the dangerous ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21D55/00

Inventor 夏元海张荣魁

Owner 苏州托克斯冲压设备有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com