A piezoresistive pressure-measuring plug for a combustion engine

A piezoresistive, internal combustion engine technology, applied in the direction of internal combustion engine testing, measuring devices, measuring rapid changes, etc., can solve problems such as sensor signal deviation, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

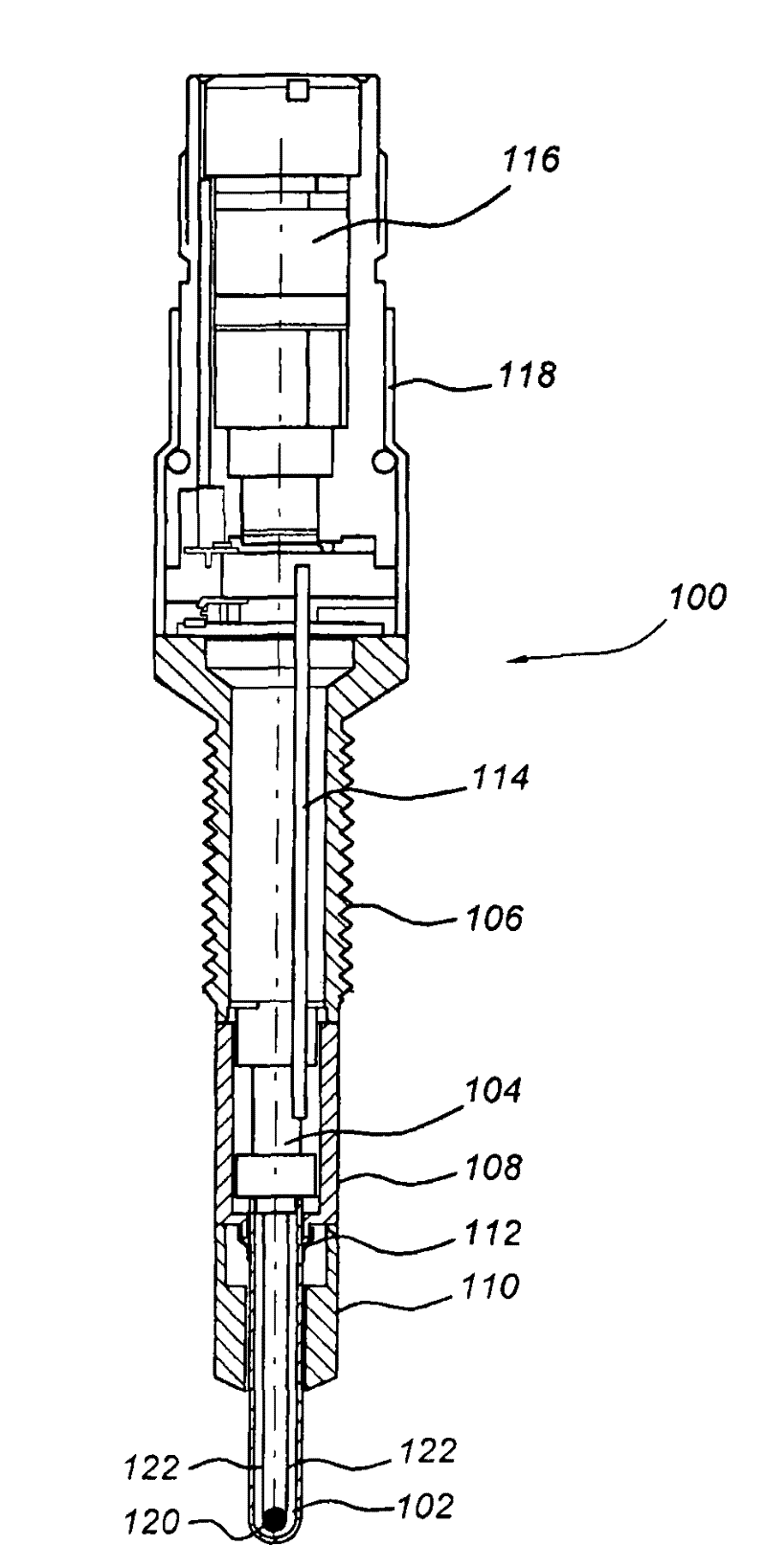

[0035] exist figure 1 A first embodiment of a pressure-measuring plug 100 according to the invention is shown in . The pressure measurement plug 100 comprises a plug stem 102 , a plug body 110 , 108 , 106 , a sensing structure 104 , a PWB 114 provided with sensor electronics and a sensor electrical connection 116 . The sensor electrical connection 116 is arranged in a housing 118 arranged to seal the cavity in the plug body 106, 108, 110 in which the sensing structure 104 and sensor electronics 114 are located from the external environment.

[0036] exist figure 1In the example of embodiment shown in , the plug bodies 110, 108, 106 include a plug body lower portion 110, a plug body middle portion 108, and a plug body upper portion 106, which are mechanically connected together. The lower part 110 of the plug body is arranged on the combustion chamber side and has a sealing cone, by means of which the pressure measuring plug is sealed off from the combustion pressure at the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonance frequency | aaaaa | aaaaa |

| resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com