Combined machine for assembly, disassembly and balance tests of tires as well as method for manufacturing and using same

A technology of balance test and tire disassembly, applied in static/dynamic balance test, tire installation, tire parts and other directions, it can solve the problems of large handling distance and inconvenience, and achieve compact structure, shortened distance, and common land occupation. area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

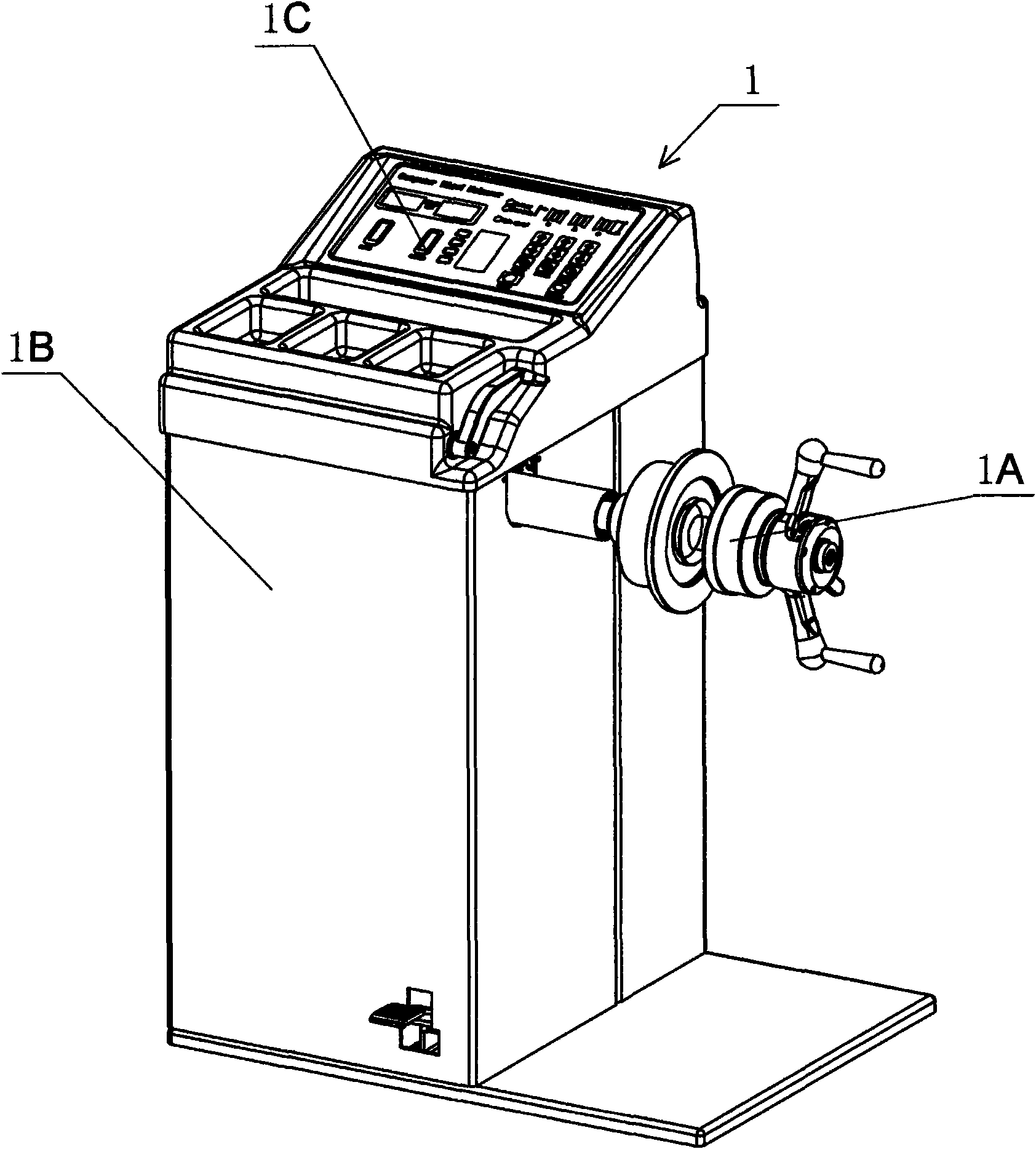

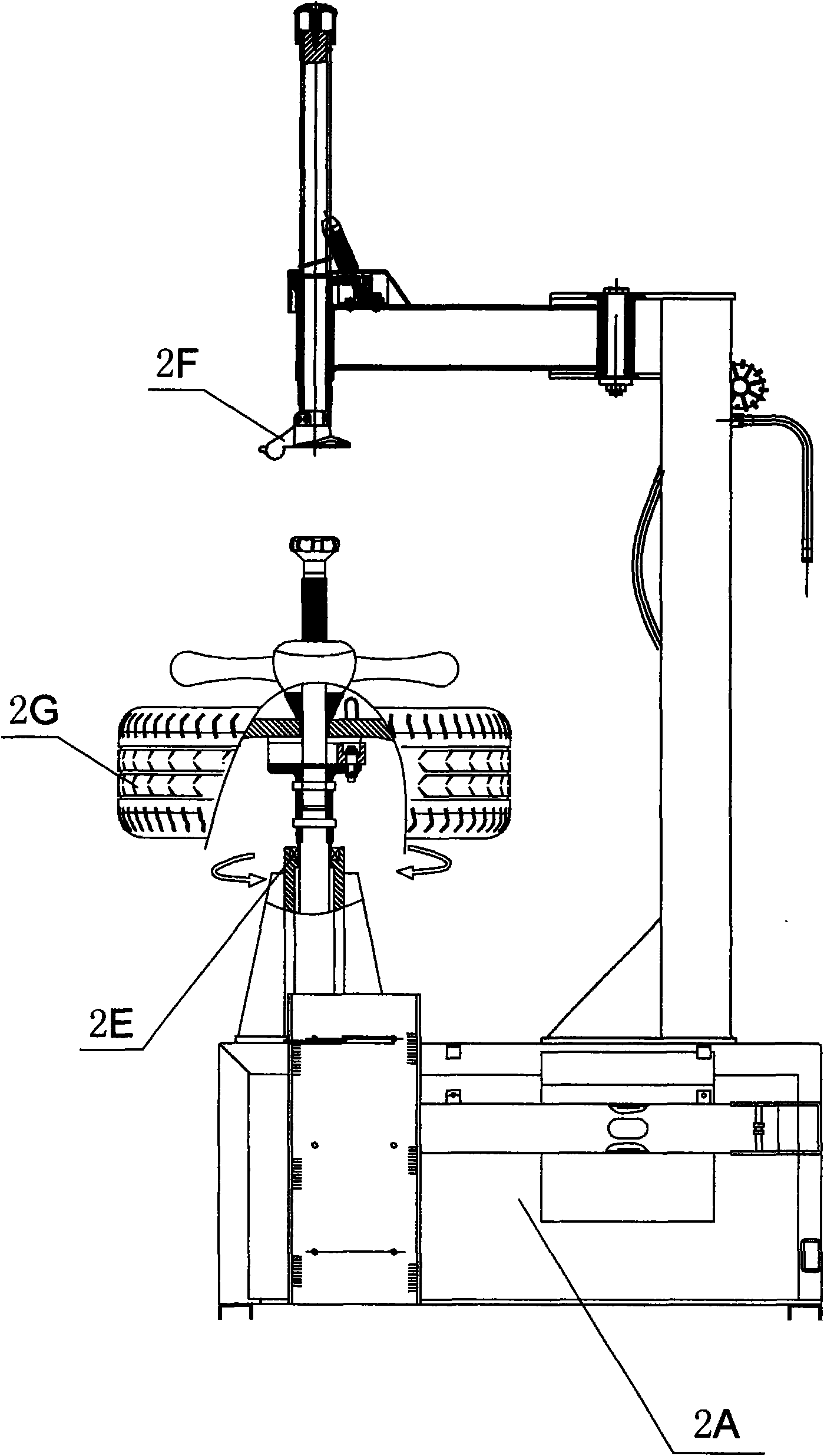

[0030] 1. Tire dismounting and balance test combined machine (combined machine or "combined device"), which includes a tire dismounting device and a tire balance test device. Regarding the tire dismounting device, the rear of the tire dismounting device base 2A A tire beading shovel 2B is attached to the side, and a handle 2C is located above the beading shovel. A shovel arm assembly 2D is connected between the tire beading shovel and the frame 2A. The shovel arm assembly 2D protrudes from the beading shovel and its handle 2C. On one side of the machine base 2A, there is a tire fixing device 2E on the front top of the machine base 2A and a dismounting head 2F on the rear top of the machine base 2A. Regarding the tire balance test device, it includes a chassis 1B, a chassis lozenge The data input device 1C and the tire installation shaft assembly 1A are characterized in that: there is a gap in the chassis 1B, and the three-dimensional space position of the gap 1D is: there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com