Thermal head

A technology of thermal head and heating part, applied in the field of thermal head, can solve the problems of ribbon wrinkling, difficulty in grinding, ribbon breakage, etc., and achieve the effect of uniform heating distribution, good gloss and image degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

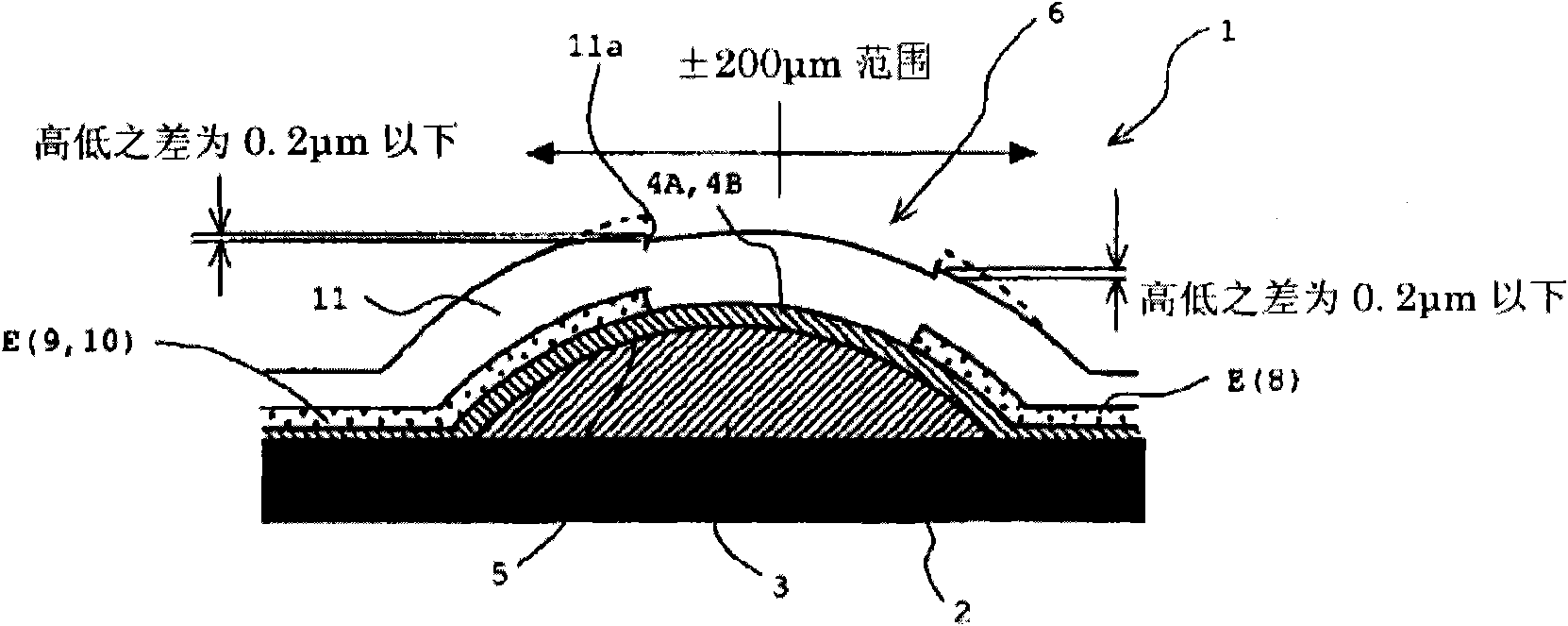

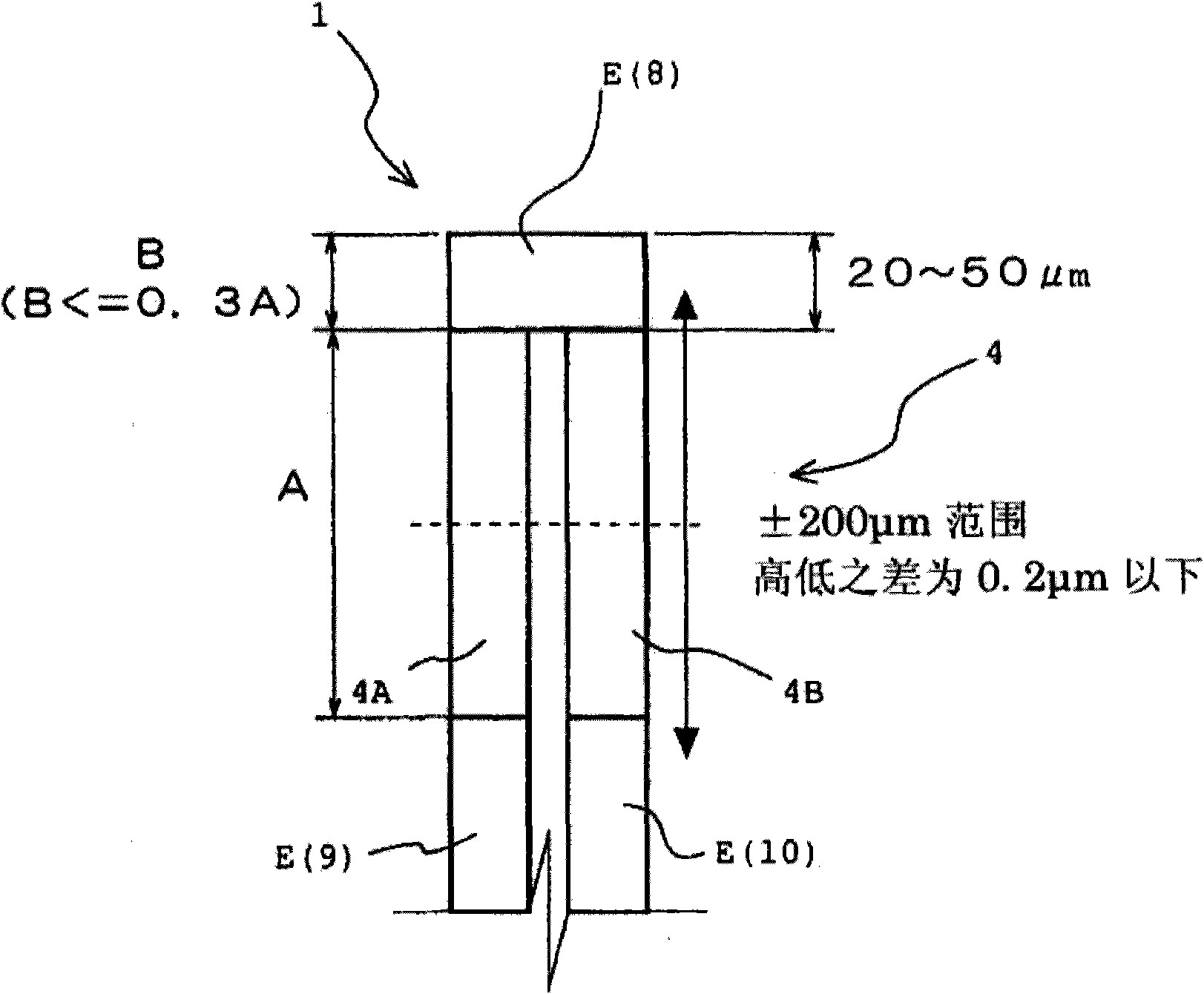

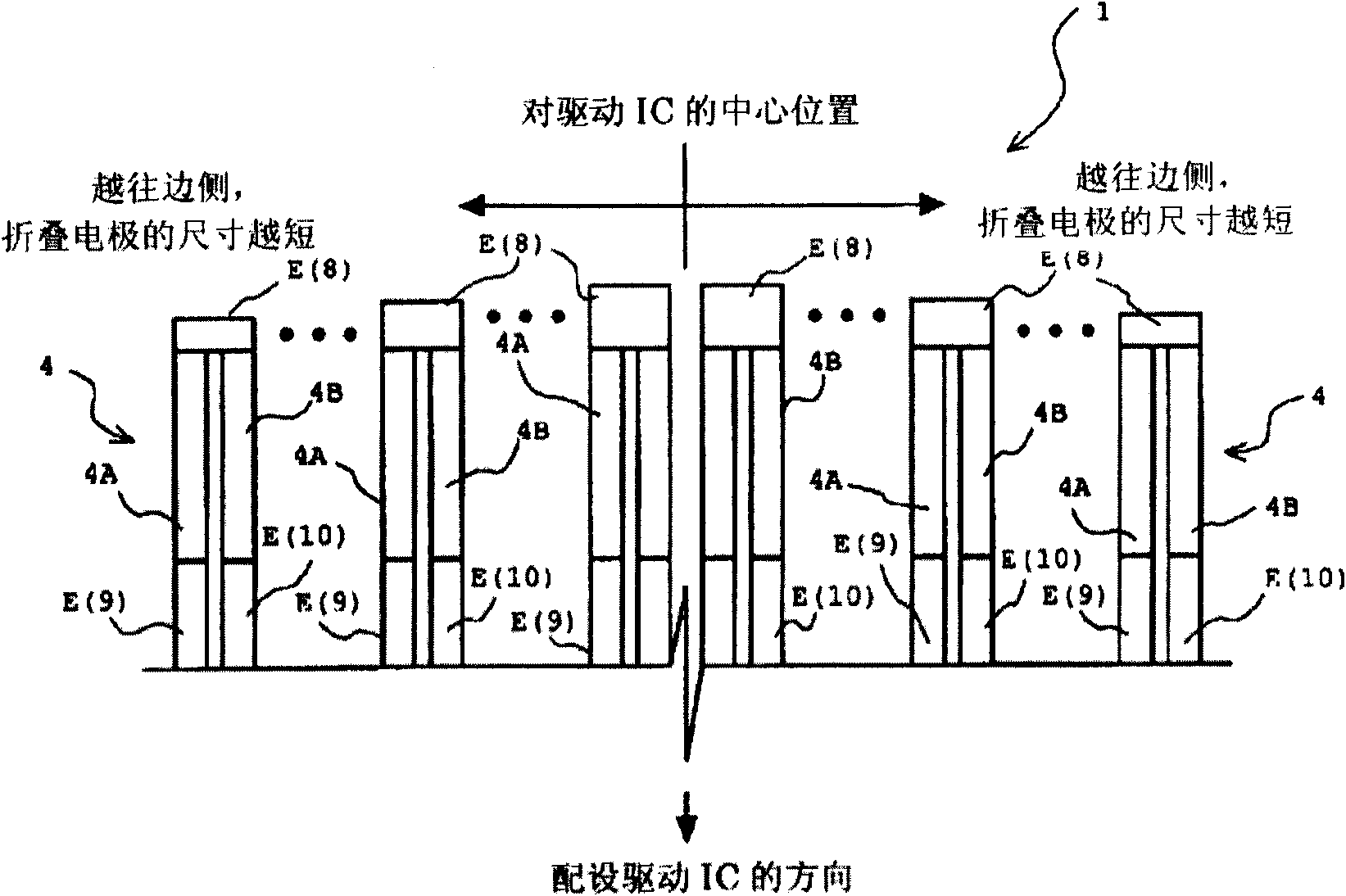

[0036] Such as figure 1As shown, the thermal head 1 of this embodiment includes a heat dissipation substrate 2 . A plurality of driver ICs (not shown) arranged in line in the main scanning direction perpendicular to the recording direction are arranged on the above-mentioned substrate 2 . Moreover, a heating element 6 is formed on the above-mentioned substrate 2, and the heating element 6 has: a heat storage layer 3 formed in a cylindrical shape with a heat insulating material such as glass; A pair of effective heating parts 4A, 4B of the heating resistor 4; an insulating layer (not shown in the figure), covers the surface of each heating resistor layer 5 and defines the plane size of the heating resistor 4, that is, the main plane perpendicular to the recording direction. The dimension in the scanning direction (width dimension) and the dimension in the sub-scanning direction (length dimension) serving as the recording direction; and the electrode layer E are composed of Al ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com