Hoisting traction mechanism of arm line-like cantilever crane

A traction mechanism and crane technology, applied in the direction of crane, clockwork mechanism, hoisting device, etc., can solve the problems such as the large cantilever is no longer suitable, the lifting height is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

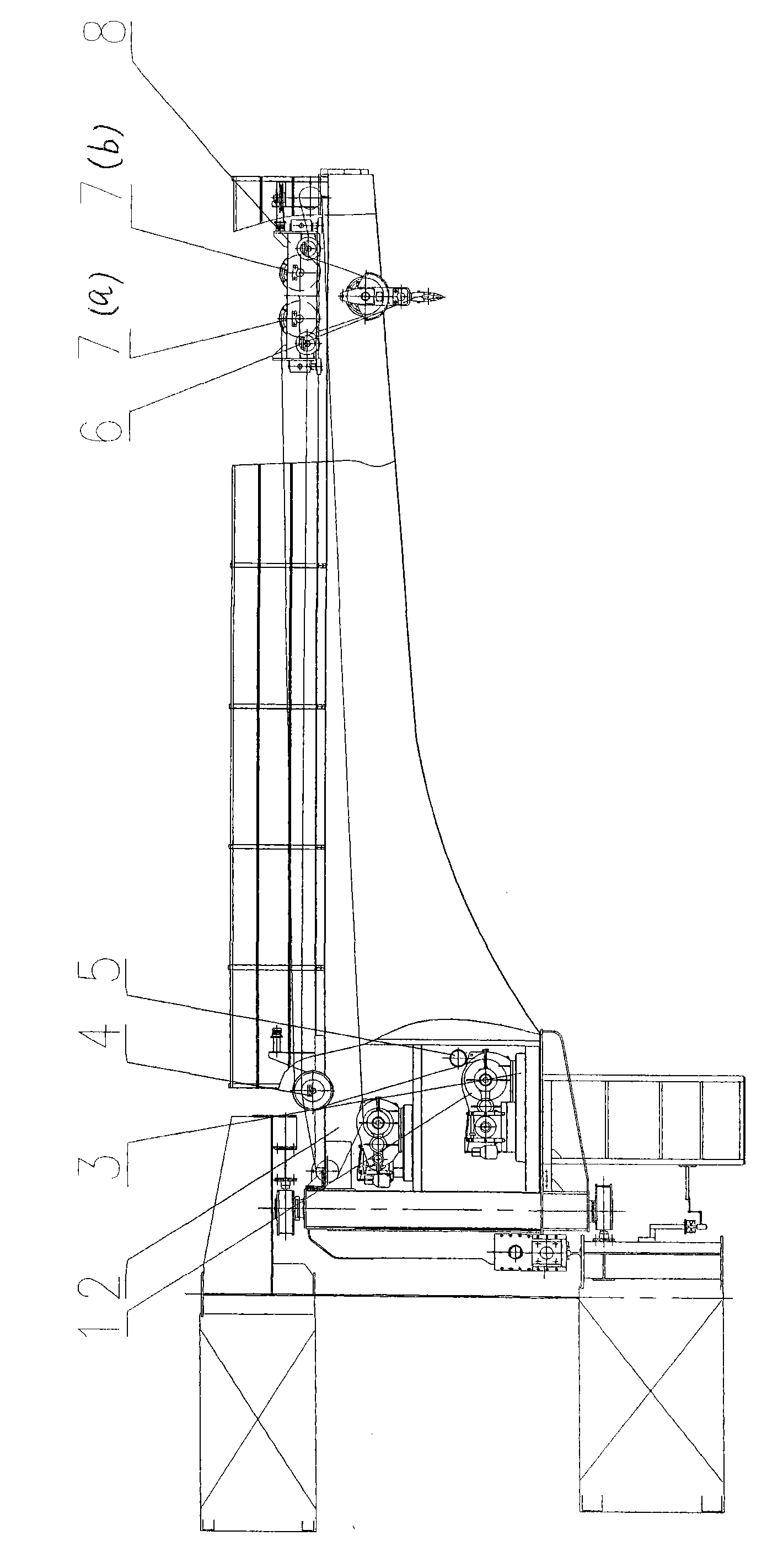

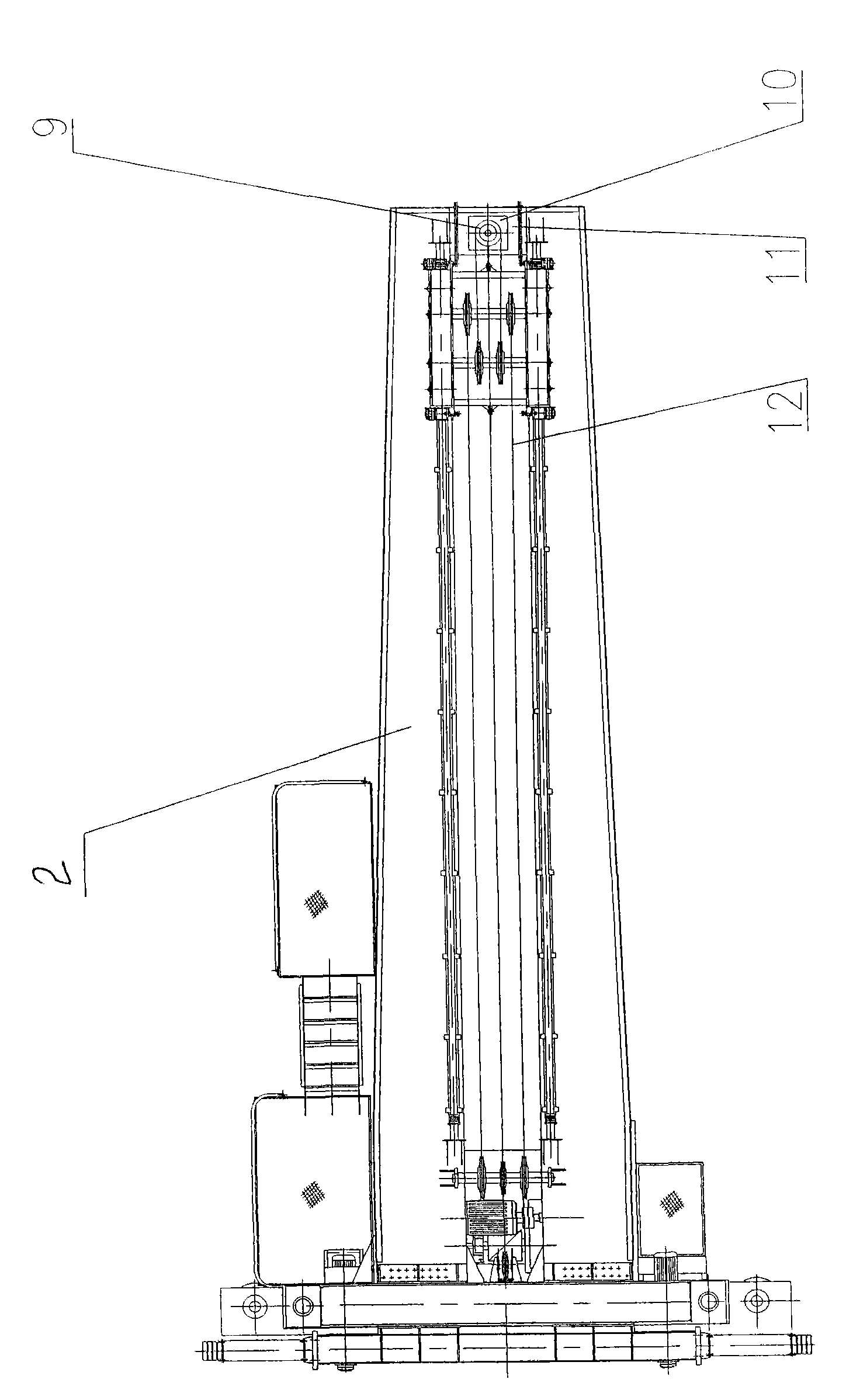

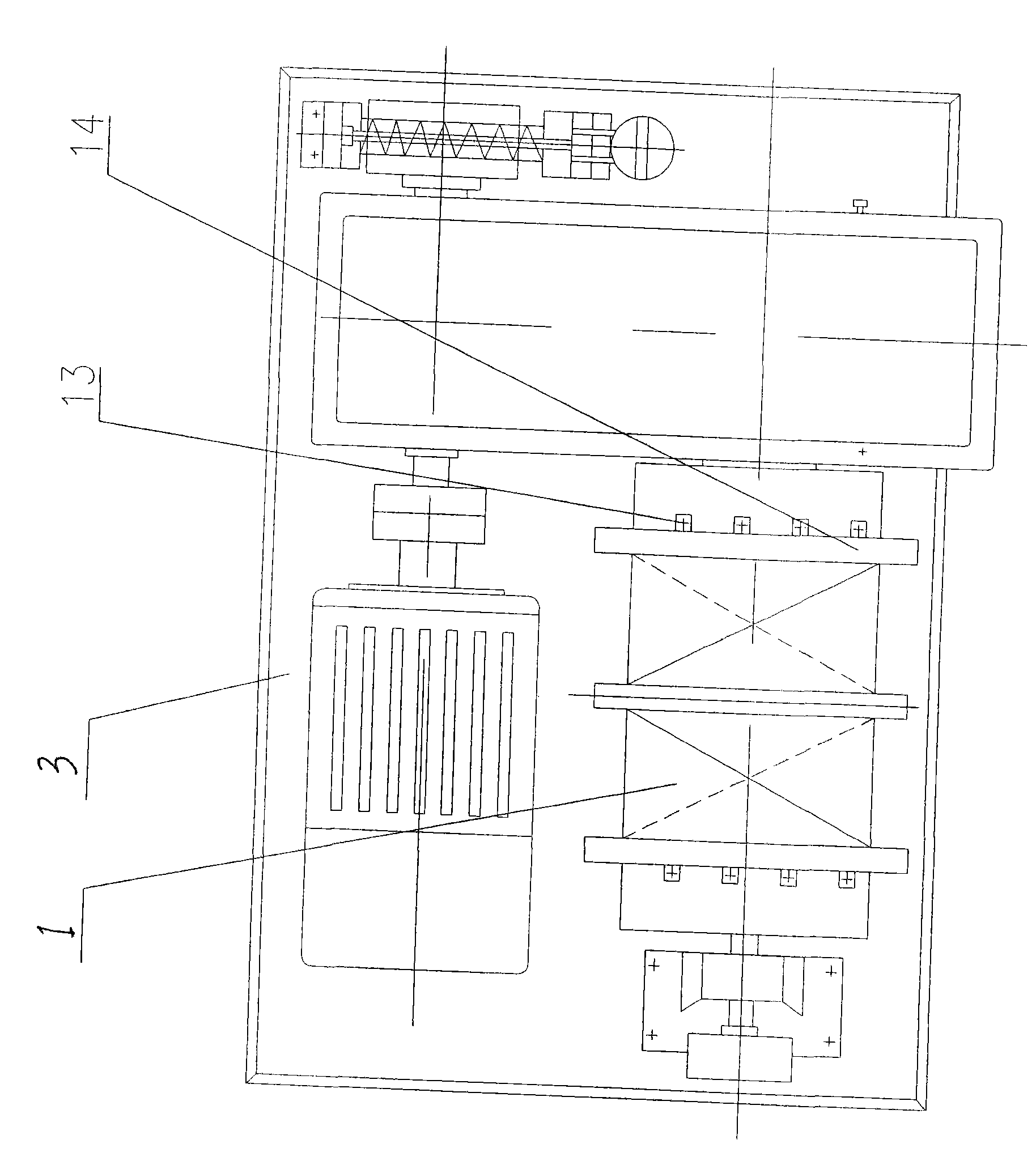

[0010] The embodiment is described in detail in conjunction with the above drawings. The lifting drive device and the reel 1 are installed on the underframe 3. The underframe is installed in the gap between the lower parts of the two main beams 2. The guide pulley 5 is fixed on one side of the reel. The reversing pulley 4 is fixed on the upper end of the main beam 2, the two fixed pulleys 7 (a), (b) are fixed on the wheel box 8 of the running trolley, the 15 moving pulley is assembled with the hook pulley block 6, and the balance pulley 9 is installed on the fixed The frame 10 is fixed on the end beam 11 through connecting bolts, and the steel wire rope 12 is fixed on both sides of the reel retaining ring 14 with the pressure plate 13. Steel core steel wire rope, the driving device of the lifting traction mechanism of the present invention adopts an AC frequency conversion speed regulation system, and drives the double Libas drum through the frequency conversion motor, brake, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com