Universal rotating spray head of high-pressure and high-temperature cleaning machine

A high-pressure, high-temperature, rotating nozzle technology, applied to spraying devices with movable outlets, spraying devices, cleaning methods and appliances, etc., can solve the problems of limited decontamination ability, unsatisfactory cleaning effect, and affecting cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

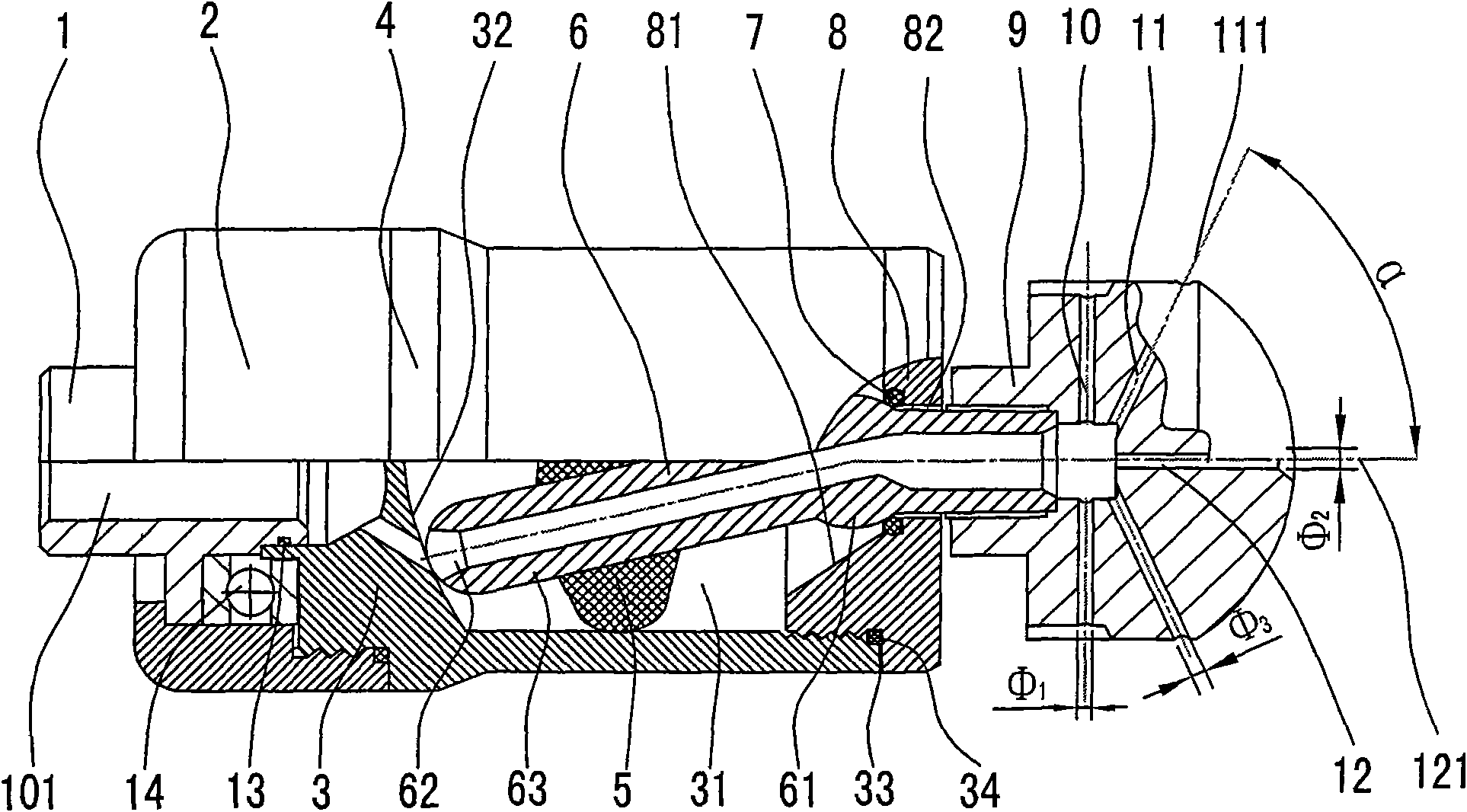

[0008] The universal rotary nozzle of the high-pressure high-temperature cleaning machine of the present invention, such as figure 1 Shown, comprise spray gun connection head 1 and spray head body 9, be shaped on water inlet hole 101 in the spray gun connection head 1, be shaped on nozzle in the spray head body 9, it is characterized in that the nozzle of described spray head body comprises axial straight nozzle 12, The radial straight nozzle 10 and the shaft, the oblique nozzle 11 between the radial straight nozzles 12 and 10, the spray head body 9 is connected to the rotating rod 6, and the spray gun connection head 1 is connected to the rotating pad 3 through the rotating screw sleeve 2 At one end, a bearing 14 and a sealing pad 13 are installed at the connection. A swing chamber 31 is formed in the rotating pad 3. The other end of the rotating pad is connected to the rotating fixed cover 8. There is a seal 34 at the connecting point. The rotating fixed cover is formed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com