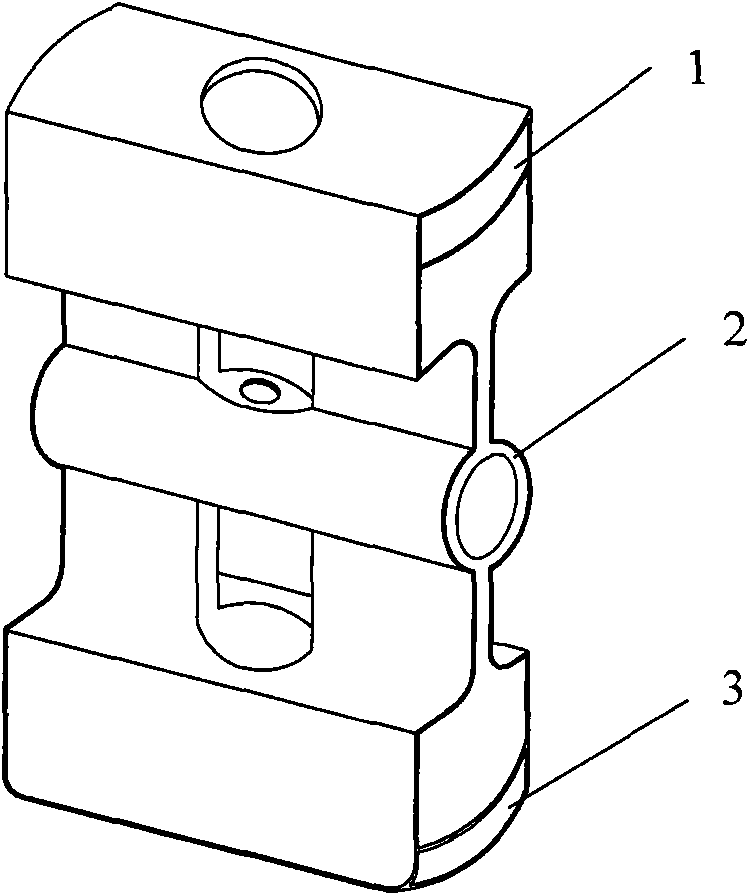

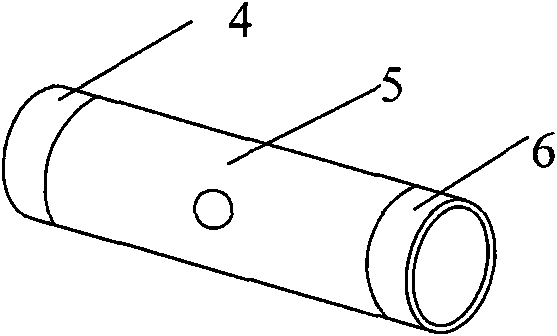

Graphite tube used for graphite furnace atomic absorption spectrophotometer and preparation method thereof

A graphite furnace atom and graphite tube technology, applied in the field of graphite tubes, can solve the problem that the anti-oxidation ability cannot meet people's expectations, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The following is a brief description of the preparation process of the graphite tube:

[0026] 1. Surface heat treatment of graphite tube

[0027] The commercially available graphite tubes are basically pyrolytic graphite tubes. Pyrolytic graphite is hydrophobic, and it must be heated (grilled) to remove the hydrophobicity, so that the metal salt solution can be evenly spread on its surface.

[0028] The method of heat treatment can be to heat the graphite tube to 2000-2500°C for air firing, or to use the formatting of the graphite tube to achieve the effect of air firing, killing two birds with one stone.

[0029] The formatting process itself is a heating process with different temperature steps from low temperature to high temperature, and this process can complete the heat treatment of the graphite tube surface. The damage to the graphite tube caused by the empty fired graphite tube is avoided.

[0030] 2. Optional metal salts

[0031] The following metal salts ...

Embodiment

[0038] Prepare graphite tubes as follows:

[0039] (1) Put a new pyrolytic graphite tube into the graphite furnace atomic absorption spectrometer, and do formatting. Remove from the instrument after cooling.

[0040] (2) Use cotton dipped in 1.5wt% lanthanum nitrate solution to smear on the pyrolytic graphite surface of the pipe body, and do not smear on the electrode contact surface. The specific treatment process is as follows: apply cotton dipped in lanthanum nitrate solution directly outside the lumen; then insert cotton into the lumen, add lanthanum nitrate solution to the cotton until it is saturated, and let the lanthanum solution penetrate into the graphite gap, after 5 minutes Take out the cotton; in order to enhance the effect, dip the cotton with lanthanum nitrate solution directly outside the lumen and apply it again.

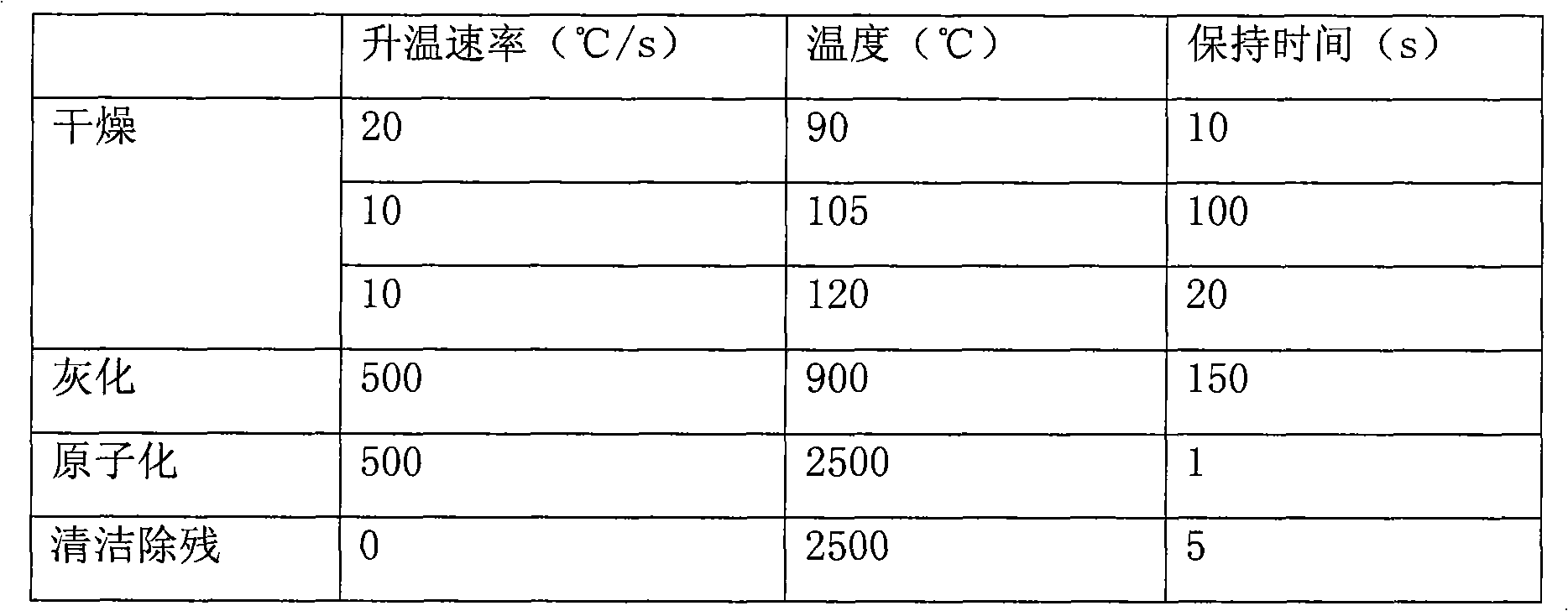

[0041] (3) The process of adding film is completed by means of sample testing. The steps of the heating program are the same as those of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com