Automatic paper feeder of automatic paper shredder and automatic paper-feeding paper shredder thereof

A technology of paper feeding device and paper shredder, which is applied in the direction of grain processing, etc., can solve problems such as hanging, and achieve the effects of prolonging life, shortening working time, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

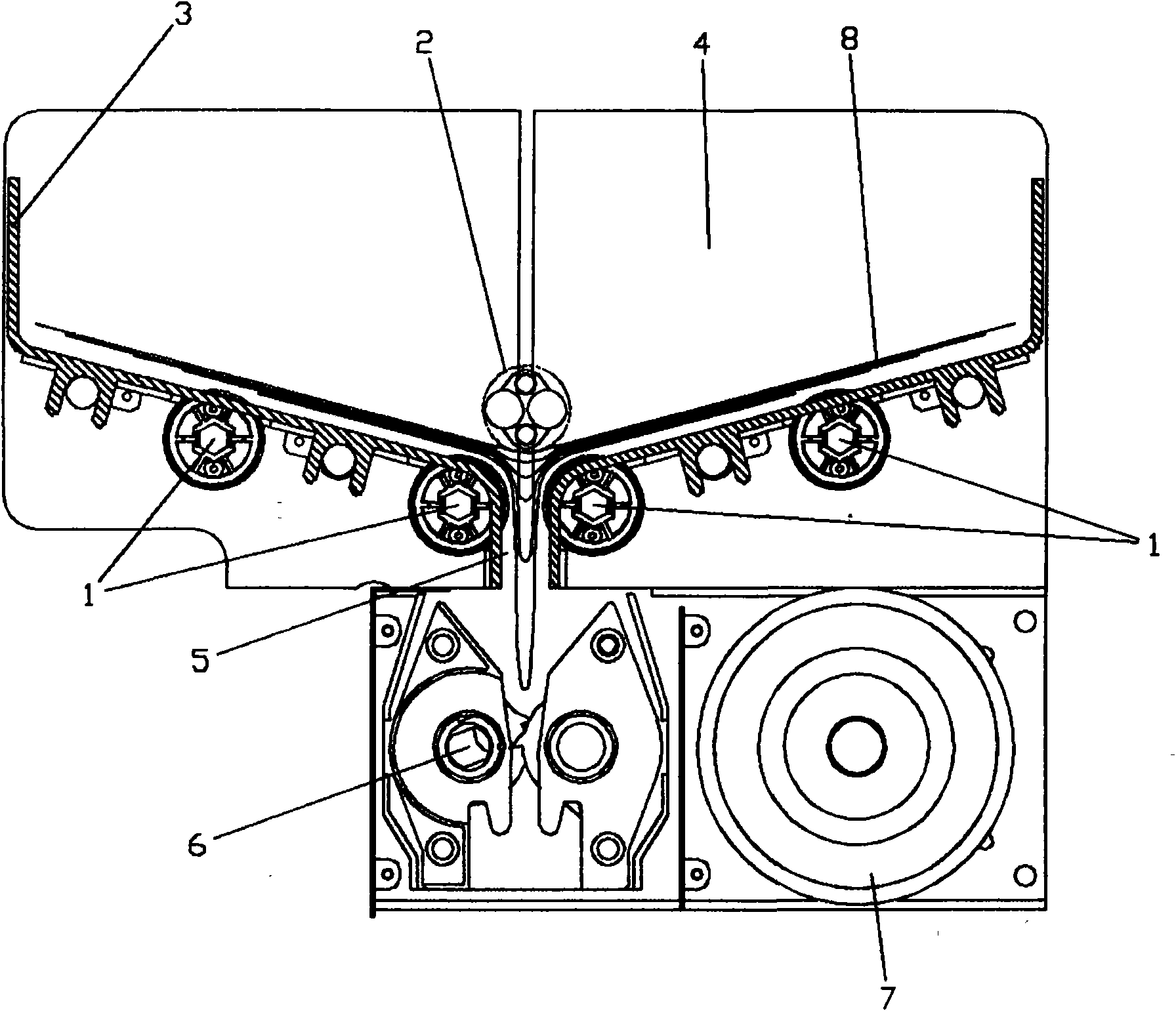

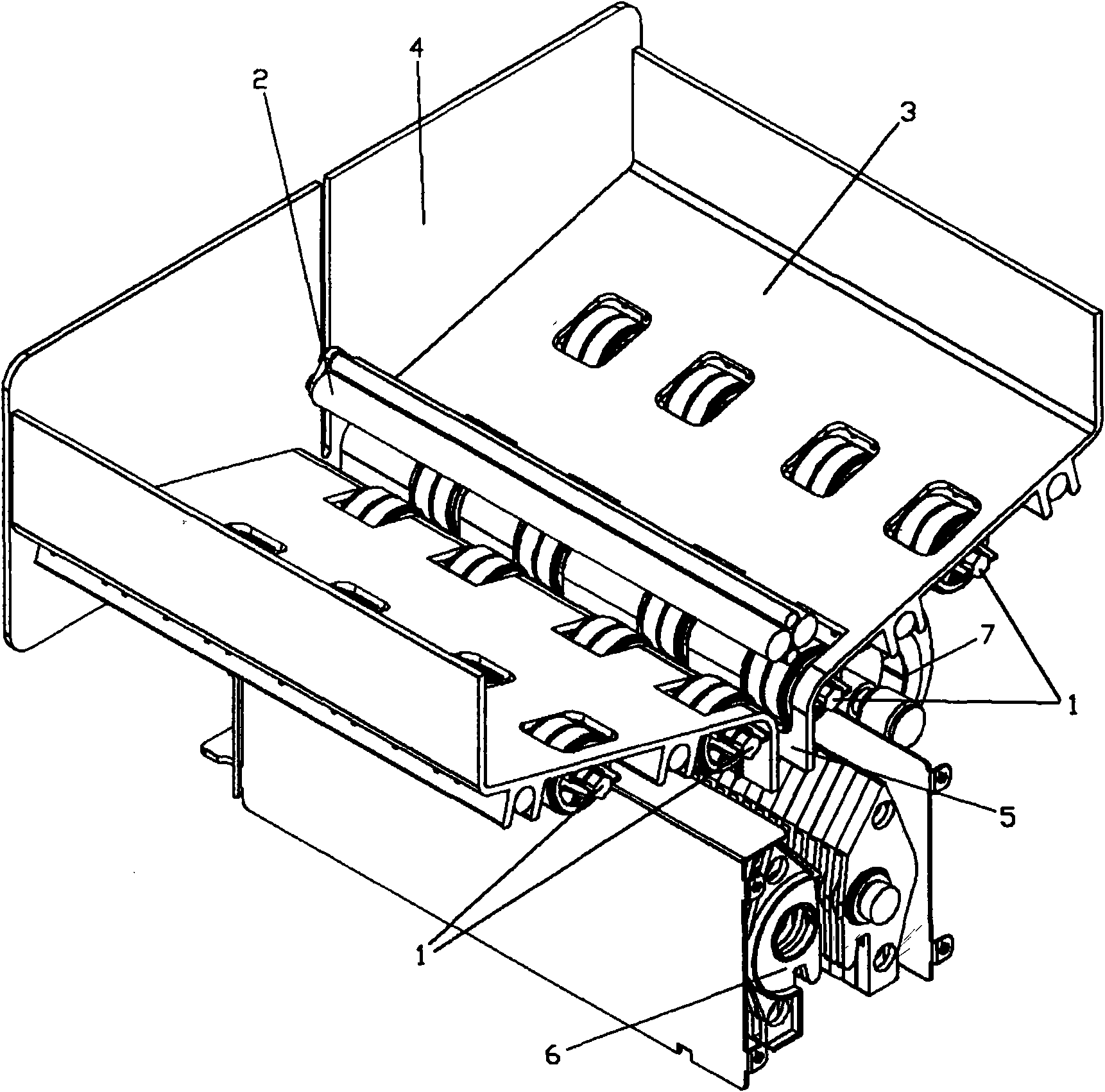

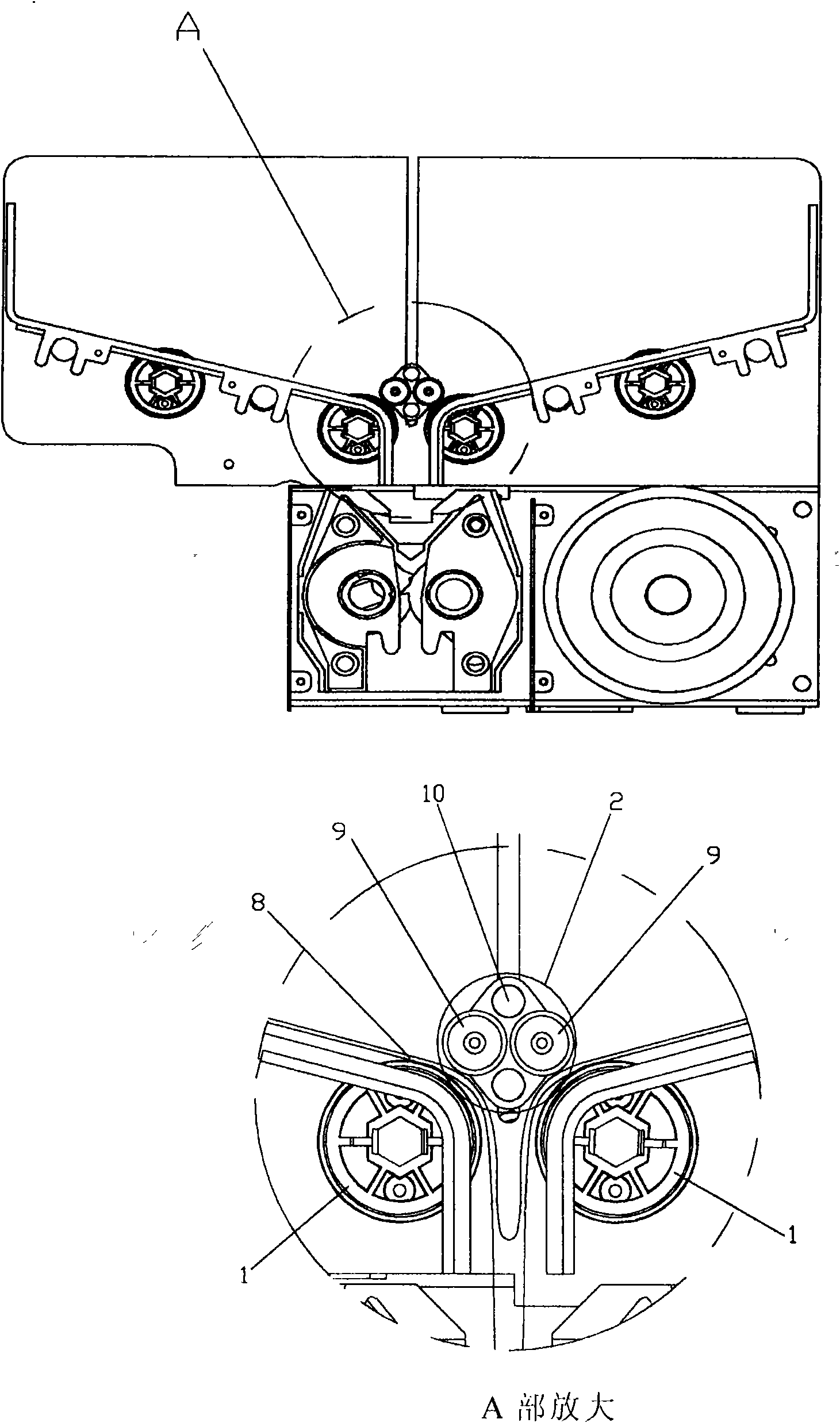

[0016] Example 1. refer to Figure 1 to Figure 3 , the automatic paper feeding device of an automatic paper shredder according to the present invention mainly includes a paper feeding board, a pressurizing part 2, a paper feeding roller 1, and an input port 5. The paper feeding board is located at the upper part of the paper shredder and includes two The end guide plate 3 and the side guide plate 4 can place many documents to be shredded, and guide the documents 8 to be shredded to the input port; the pressurizing part 2 is pressed on the paper on the paper feeding board; the input port 5 is located at The middle part of the paper feeding board; the paper feeding roller 1 is located on both sides of the input port 5, and the two sides are respectively two groups, which are made of rubber material.

[0017] The paper feeding plate is a tilt mechanism with high ends and low middle, so that the documents to be shredded can enter the above input port more easily.

[0018] The ab...

Embodiment 2

[0020] Example 2. refer to Figure 4 , an automatic paper feeding device of an automatic shredder according to the present invention mainly includes a paper feeding roller 1, a paper feeding board, an input port 5, a spring 7, a pressure roller 9, and an upper cover 11, and the paper feeding board is located at The upper part of the paper shredder includes guide plates 3 at both ends and side guide plates 4, which can place many documents to be shredded and guide the documents 8 to be shredded to the input port; the pressurizing part 2 presses the paper on the above-mentioned paper supply board The input port 5 is located in the middle of the paper feeding board; the paper feeding roller 1 is located on both sides of the feeding port 5, and the two sides are respectively two groups, which are rubber materials; the upper cover wraps the above paper feeding board, And it is connected with the above-mentioned pressurizing part 2 by a spring 7 . When the loam cake 11 is opened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com