Assembly type hollow cathode heater

A hollow cathode and heater technology, applied in the direction of ohmic resistance heating, discharge tube solid thermionic cathode, electric heating device, etc., can solve the problems of reducing the strength of the lead wire, not easy to form, raising the temperature of the lead wire, etc., to improve the anti-vibration ability , good reliability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

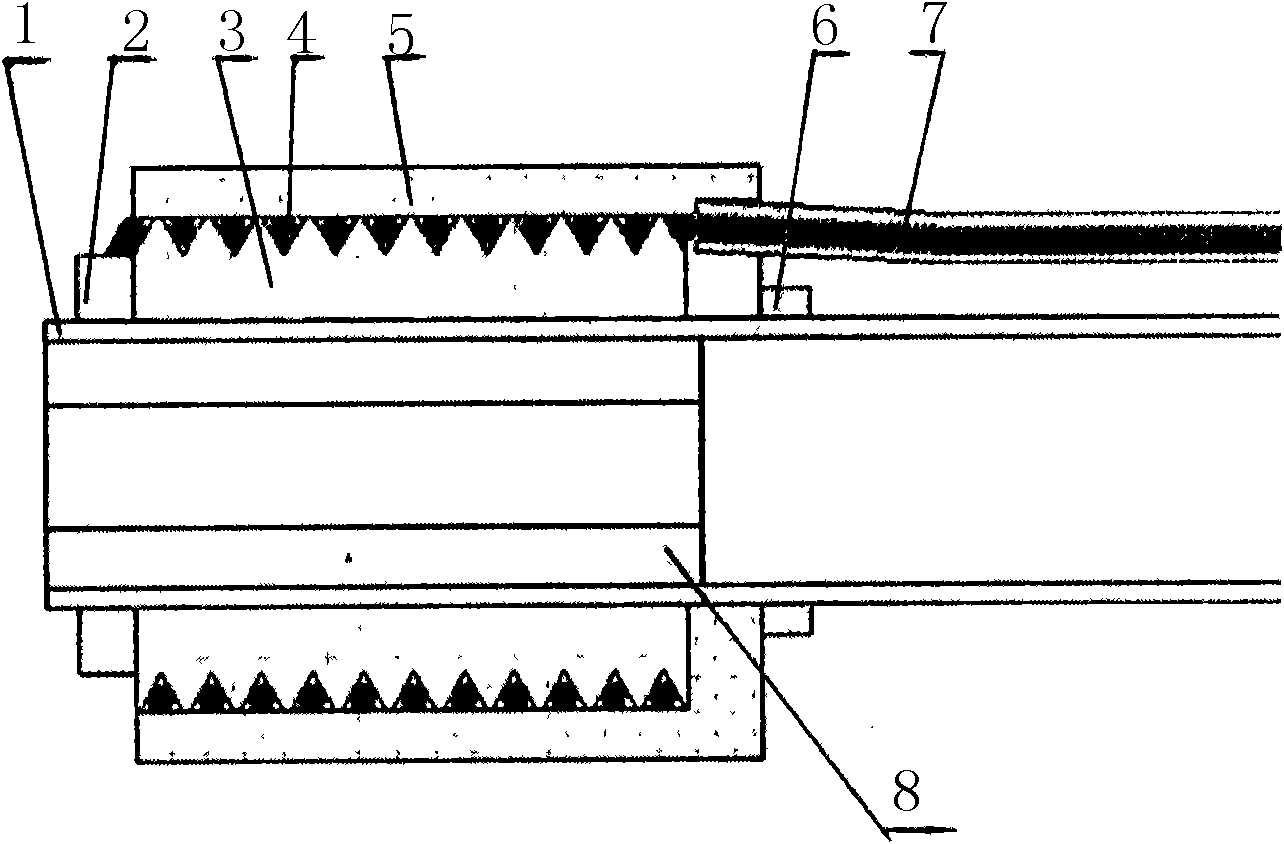

[0014] Such as figure 1 As shown, it is the hollow cathode heater of the present invention, which is the basic form of the present invention. The technical solution of the present invention is: assembled hollow cathode heater, comprising cathode tube 1, front positioning ring 2, ceramic skeleton 3, heating wire 4. Ceramic jacket 5, rear positioning ring 6, lead pipe 7 and emitter 8. The ceramic skeleton 3 and the cathode tube 1 are connected by a tight fitting suit. There is a spiral groove on the outside of the ceramic skeleton 3. The ceramic jacket 5 cooperates with the ceramic skeleton 3 to limit the heating wire 4 in the spiral groove of the ceramic skeleton. The front positioning ring 2 , The rear positioning ring 6 limits the axial displacement of the ceramic skeleton 3 and the ceramic jacket 5 in the cathode tube. One end of the heating wire is welded on the cathode tube 1, and the other end is sleeved on the lead tube 7.

[0015] Such as figure 1 As shown, at first,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com