Key lifting switch device and assembling fixture and assembling technology thereof

A technology for lifting switches and assembling fixtures, which is applied in the direction of electric switches, electrical components, circuits, etc. It can solve the problems of affecting production efficiency, inconvenient installation, and difficult realization of fixture accuracy, and achieves improved assembly efficiency, reduced complexity, and excellent assembly. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

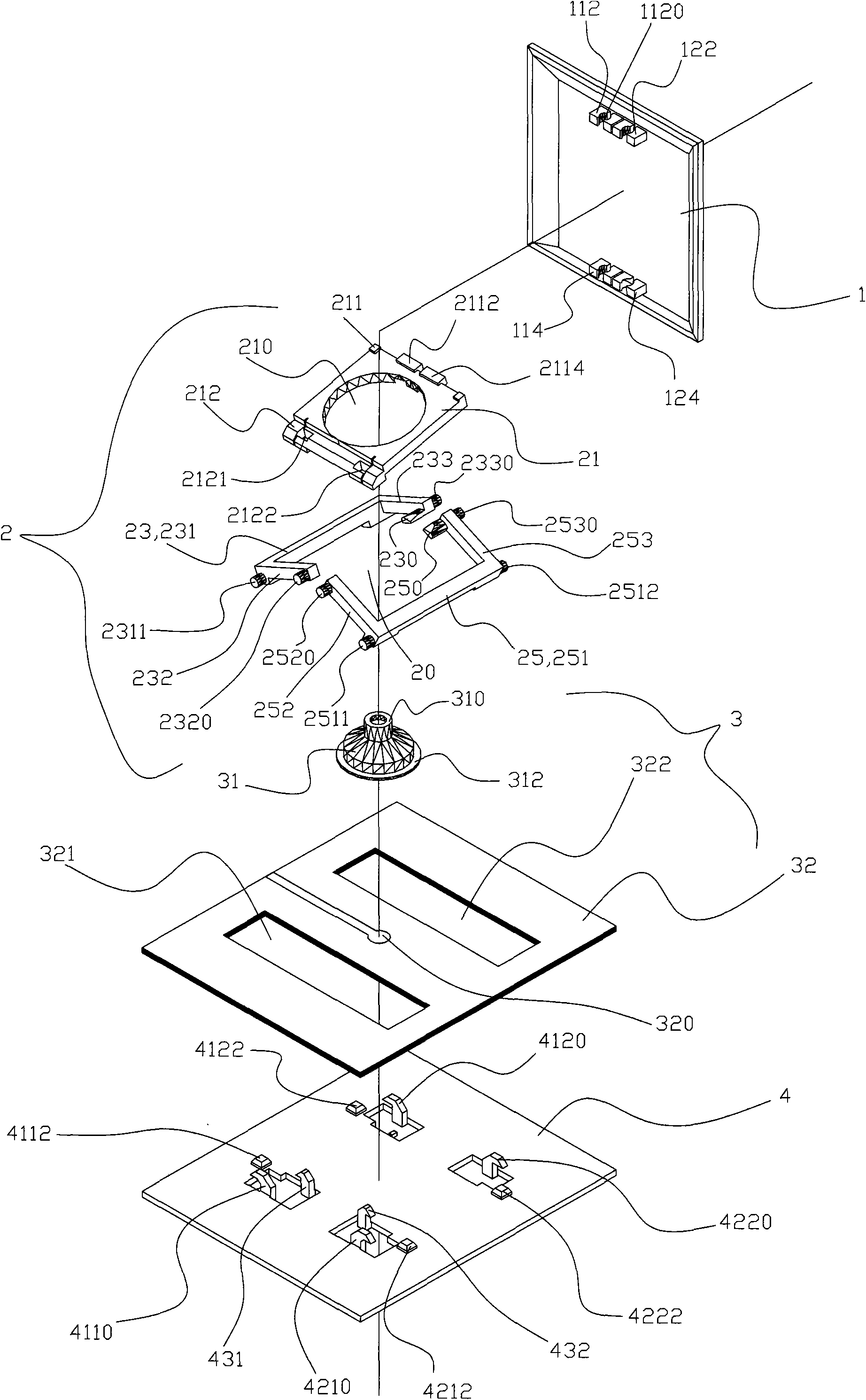

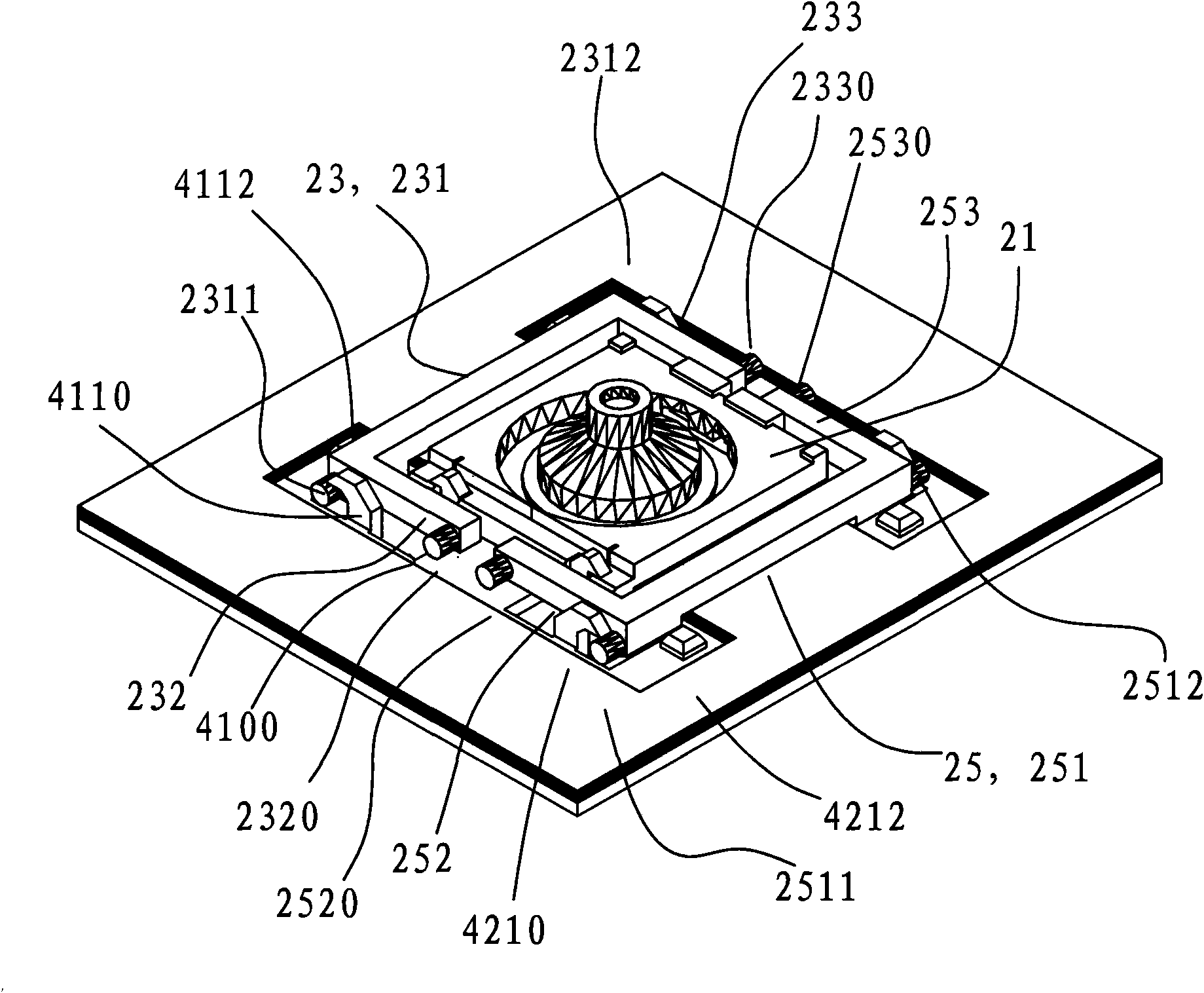

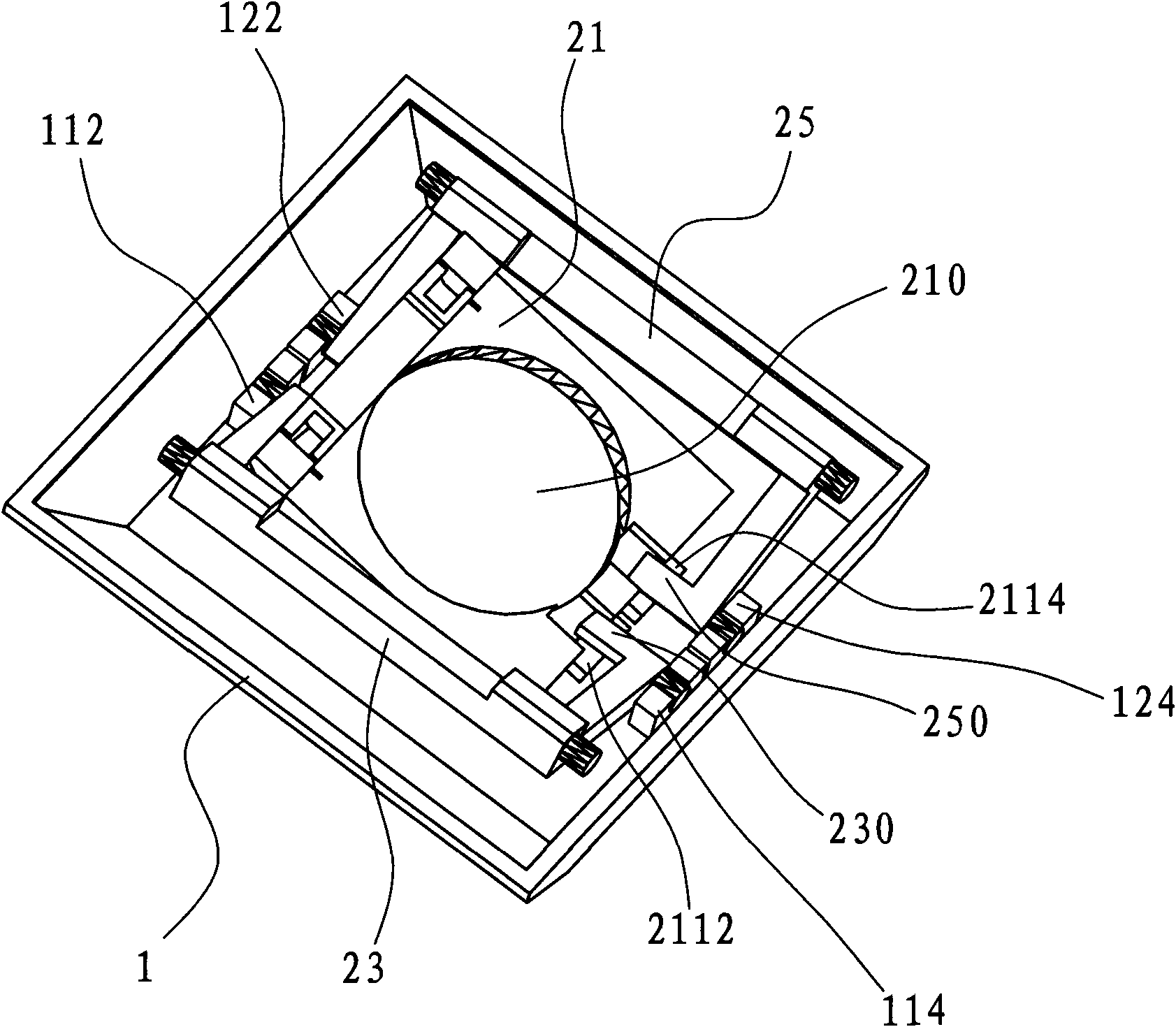

[0055] refer to figure 1 As shown, the key lifting switch device of the present invention is composed of a keycap 1, a telescopic assembly 2, a switch mechanism 3 and a support plate 4. The main improvement of the key lifting switch device of the present invention will be disclosed as follows—the telescopic assembly 2 and some components on the bottom surface of the keycap 1 and the upper surface of the support plate 4 related to the improvement of the telescopic assembly 2 .

[0056] Please first understand the specific structure of the telescopic assembly 2 of the present invention:

[0057] combine figure 1 and figure 2 , the telescopic assembly 2 of the present invention includes a pair of U-shaped frames 23 and 25 with a symmetrical structure and a plate-shaped synchronous slide 21 .

[0058] The U-shaped frame 23, 25 includes figure 1 The first fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com