Socket type pore-forming mold, socket type pore-forming device and method for preparing porous brick thereof

A hole-forming device and hole-forming technology, used in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of high requirements for manufacturing materials and processes, insufficient product compactness, poor impermeability and crack resistance, etc. The effect of small pore resistance, beautiful product, and enhanced impermeability and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

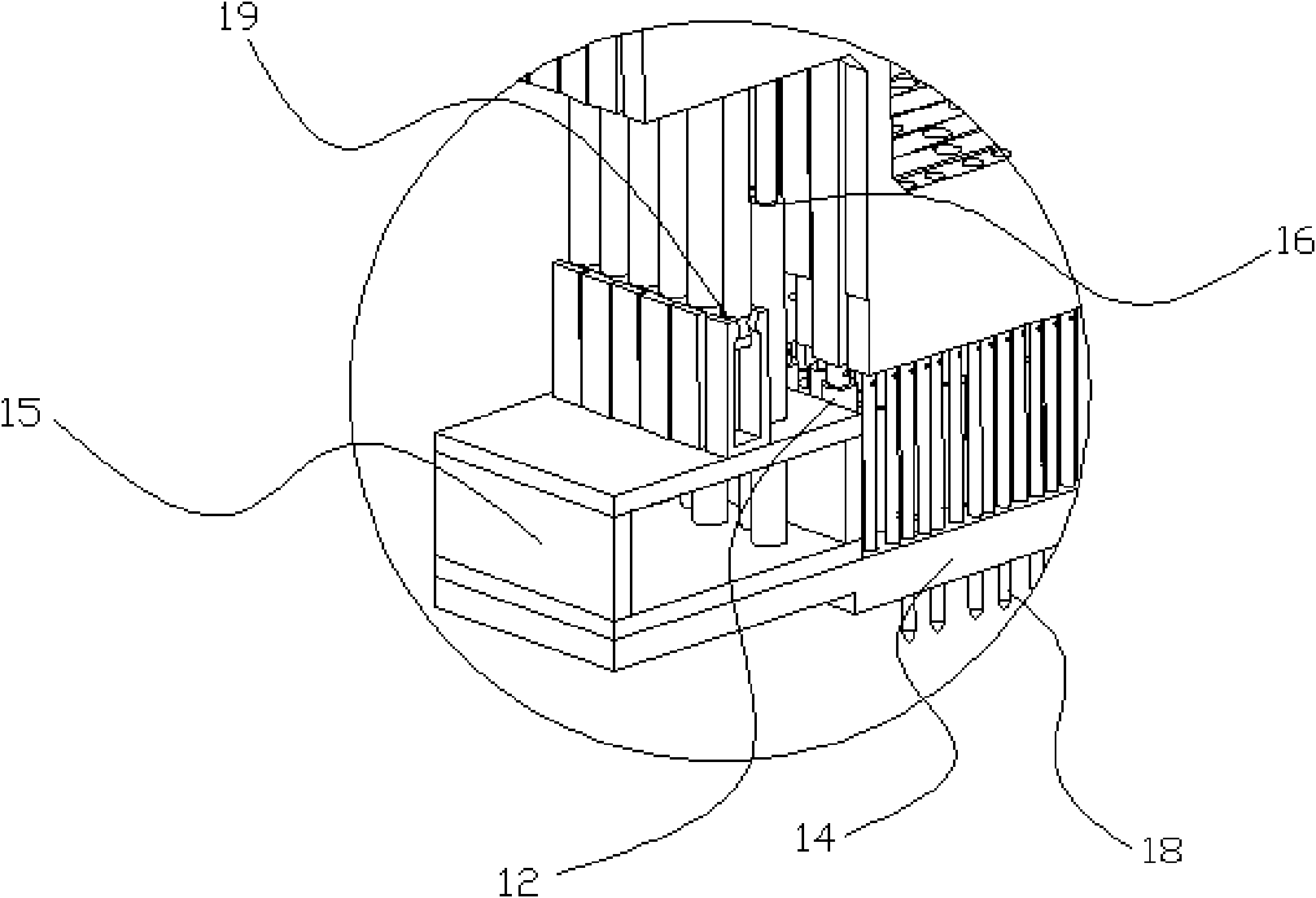

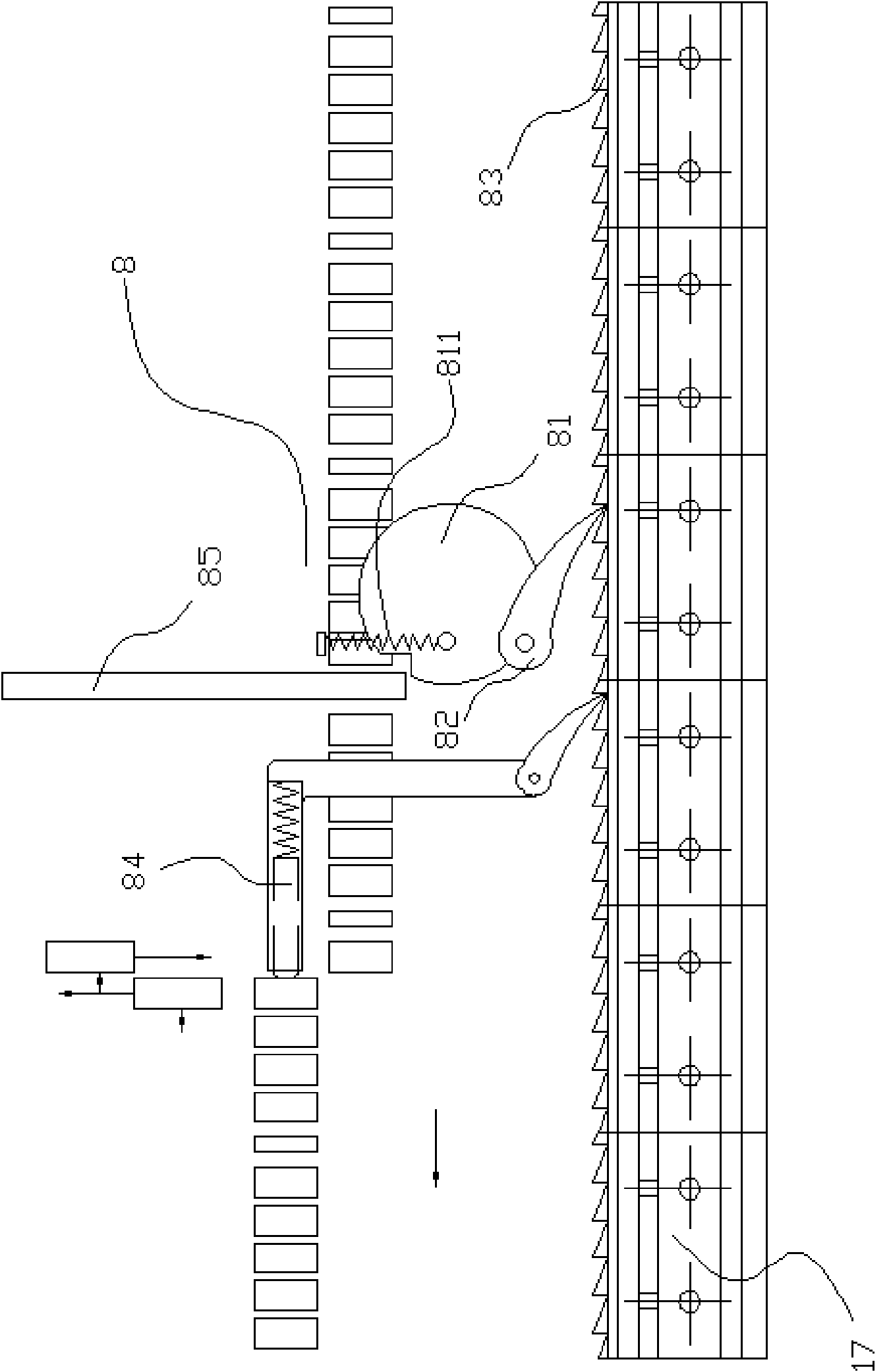

[0042] The plug-in hole-forming die of the present invention includes an upper die 1 and a lower die 2, referring to Figure 1 ~ Figure 2 , the upper mold 1 is formed by arranging a plurality of plunger beams 13 provided with hole-forming plungers 12, the hole-forming plungers 12 are distributed in rows below the plunger crossbeams 13, and the bottom of the plunger crossbeams 13 is arranged There is a jacking plate 14 corresponding to the hole-forming inserting rod 12, the two ends of the several inserting rod beams 13 are assembled together through the assembly body 15, and a guide device 16 is provided between the inserting rod beam 13 and the assembly body 15, Wherein, guide device 16 can adopt the structure that conduit and guide rod cooperate with each other, promptly conduit and guide rod are respectively installed on inserting rod crossbeam 13 and assembly 15, and guide rod is sleeved in conduit, like this when working, inserting rod crossbeam The motion of 13 is just l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com