Die cushion device comprising a hybrid drive unit

A drive device and hybrid drive technology, applied in the field of stretch pad devices, can solve the problems of destroying the force transmission mechanism and not having overload protection performance, and achieve the effects of compact structure, small moment of inertia, and reduced structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

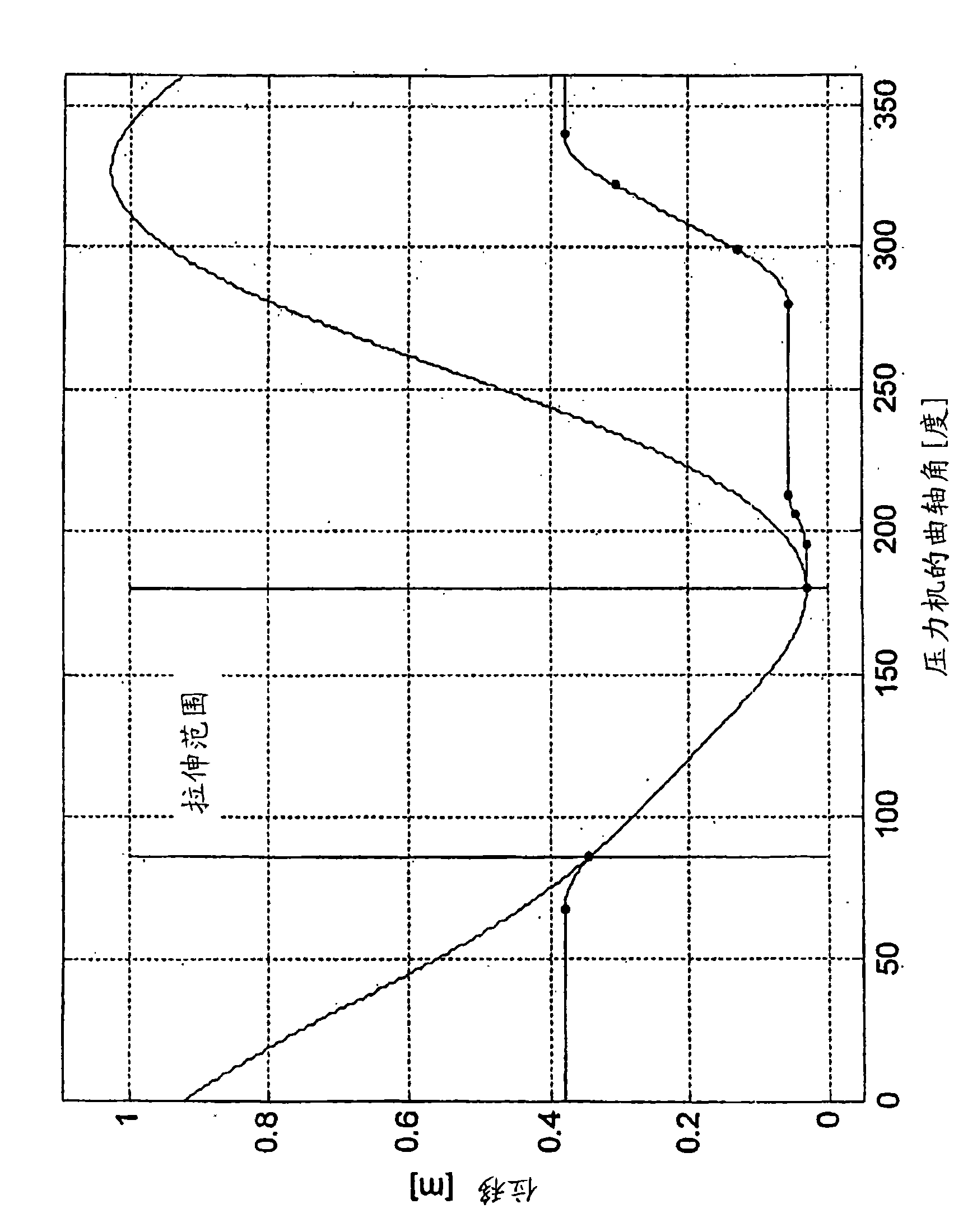

[0025] figure 1 The schematic design of a forming press 51 for stretching large-area components 10 , for example in the form of blanks 53 or sheets of synthetic material, is shown. The press has a mechanical drive 1 which moves the punch 2 together with the upper die 3 up and down. Arranged in the press table 8 is a stretching pad arrangement 50 with a hybrid drive 52 comprising a compression yoke (Druckwange) 7 and a A plurality of stretch mat modules 9 or a hybrid drive 52 . Standing on the pressing yoke 7 is a pressing bolt 6 which holds the blank carrier 4 together with the drawing workpiece 10 and acts on the drawing workpiece 10 from below with a blank holding force F53 . After placing the punch 2, the upper mold 3 is connected to the slab support 4 through the drawing workpiece 10 and pulls the slab support 4 toward the pressing bolt 6, the pressing yoke 7 and Pad modules 9 press, said tension pad modules 9 support said compression yoke 7 . Each stretching pad modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com