Soil sampler

A sampler and soil sample technology, applied in the direction of sampling devices, etc., can solve the problems of limited soil quality, slippage, unsuitable for field carrying and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

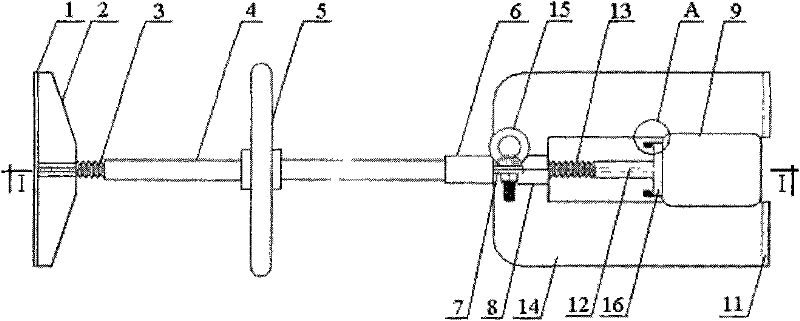

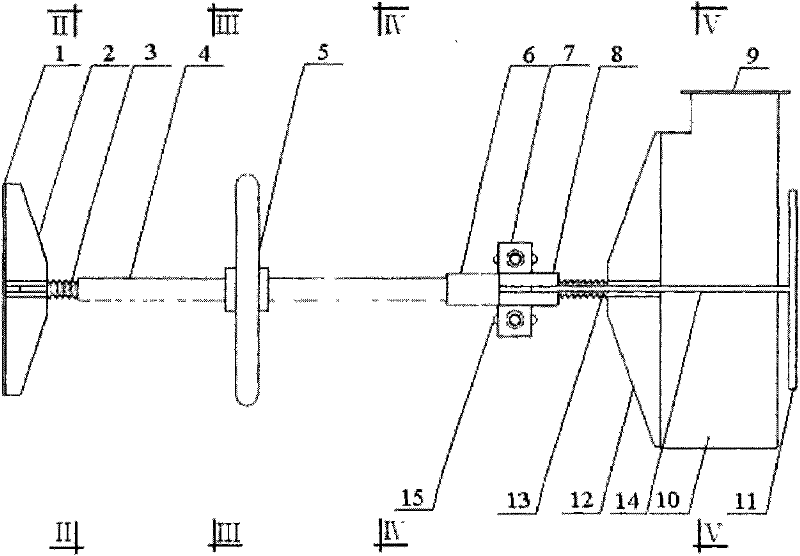

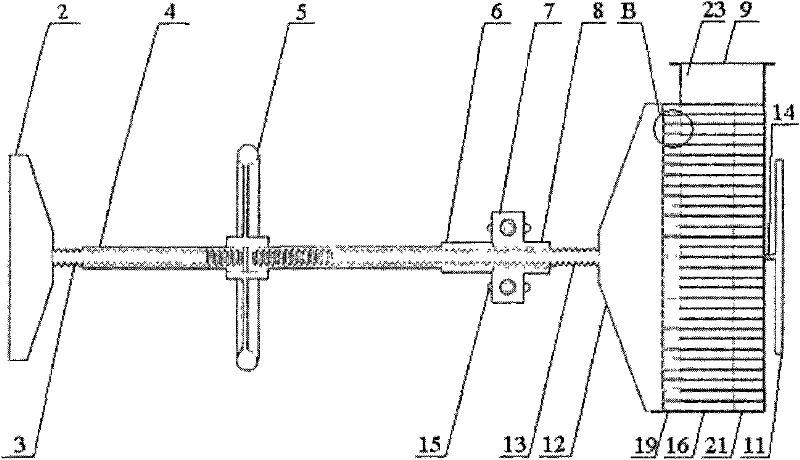

[0038] The soil sampler provided by the present invention is composed of a rear abutment, a transmission unit, a sampling head and a front abutment;

[0039] In particular, in the present invention, the direction of one end of the sampling box 21 is the front end of the present invention and its components along the horizontal direction, and the direction of one end of the rear abutment plate 1 is the rear end of the present invention and its components along the horizontal direction. At the same time, when it comes to the clockwise and counterclockwise rotation directions of the transmission handwheel 5, the user's line of sight is based on the direction from the front end to the rear end of the present invention.

[0040] Such as figure 1 , 2 , 3, and 6, the back-arresting piece is composed of a back-arriving piece abutment plate 1 and a back-arriving piece transmission rod 3; the back-arriving piece abutment plate 1 is a circular plate, and the cylindrical back-arriving pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com