Continuous pressure detection device for electric pressure cooker

An electric pressure cooker and detection device technology, which is applied to pressure cookers, fluid pressure measurement involving magnet displacement, and transmission of sensing components using an electric/magnetic device, can solve the problem of high cost of pressure detection devices, inconvenient installation and debugging, and large time drift. and other problems to achieve the effect of satisfying the maximization of food cooking nutrition, simple structure and satisfying taste requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

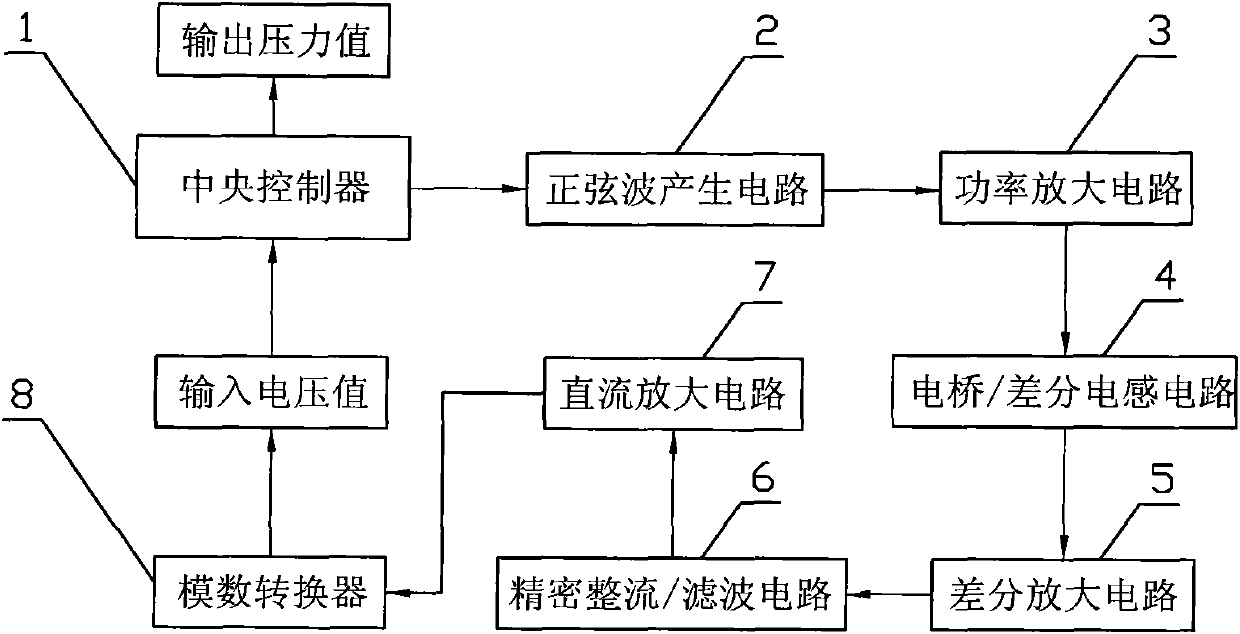

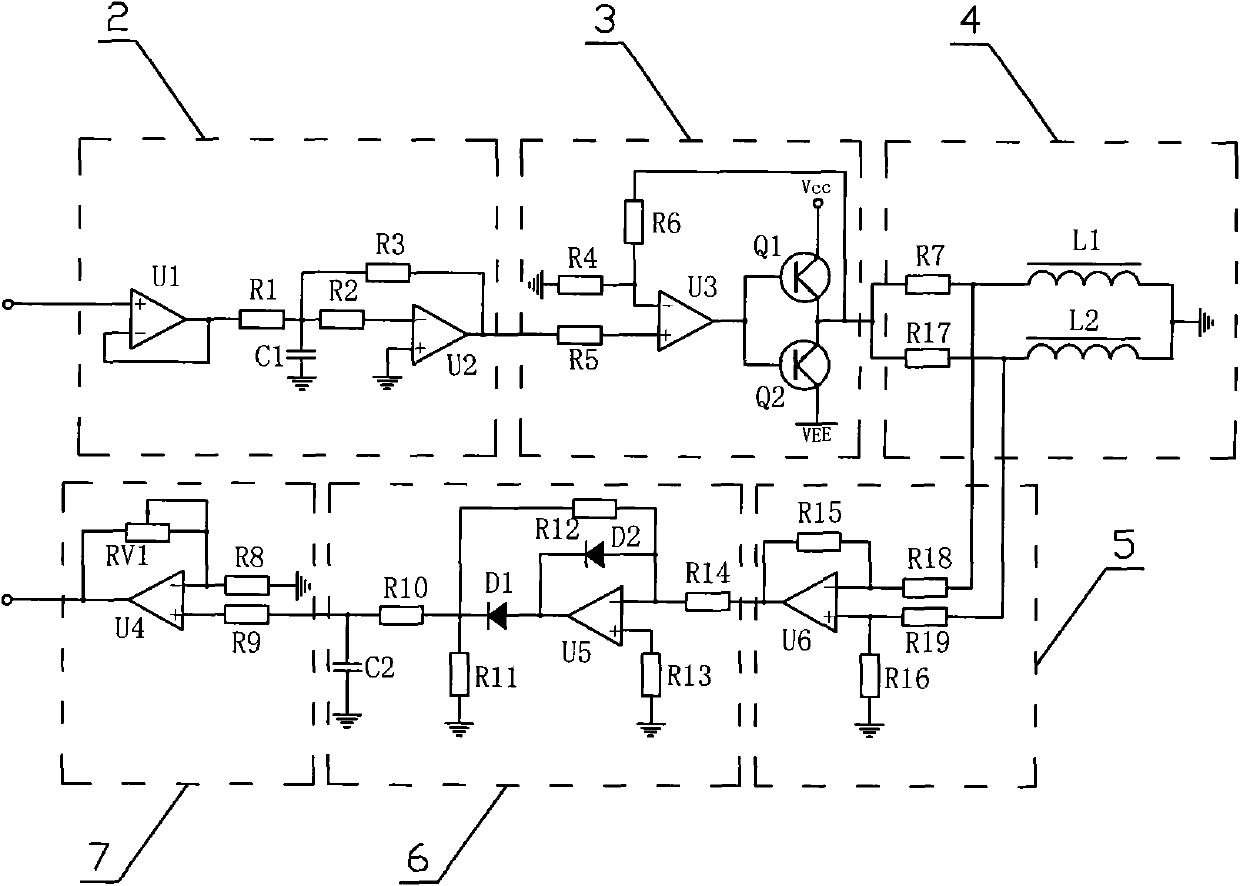

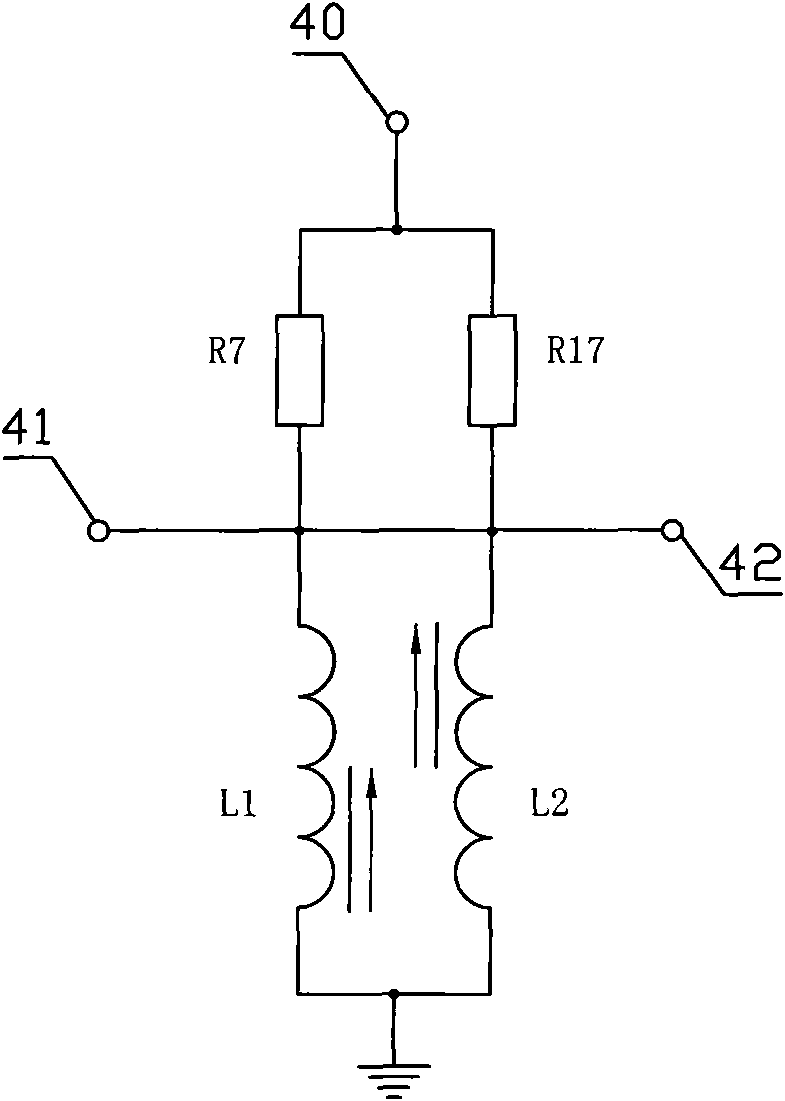

[0035] Example: such as Figure 1 to Figure 4 As shown, the pressure continuous detection device of the electric pressure cooker includes a circuit control part and a mechanical execution part, and the circuit control part includes a central controller 1, and the central controller 1 is connected with a sine wave generating circuit 2, the sine wave generating circuit 2, power Amplifying circuit 3, electric bridge and differential inductance circuit 4, differential amplifying circuit 5, precision rectification and filtering circuit 6, DC amplifying circuit 7 and analog-to-digital converter 8 are connected in sequence, and the signal processed by DC amplifying circuit 7 enters the analog-to-digital converter 8, the input voltage value is generated and entered into the central controller 1, and the central controller 1 can convert the input voltage value into an output pressure value; the mechanical execution part includes a magnetic core 9 connected to the bottom of the outer pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com