Continuous casting steel billet online hot-wire jet printing machine

A technology of hot metal and jet printing machine, applied in metal material coating process, fusion spraying, coating, etc., can solve problems such as blurred billet information, high loss of font cutting heads, and paint peeling off, etc., to achieve information Clear and recognizable, ideal marking effect, convenient quality tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

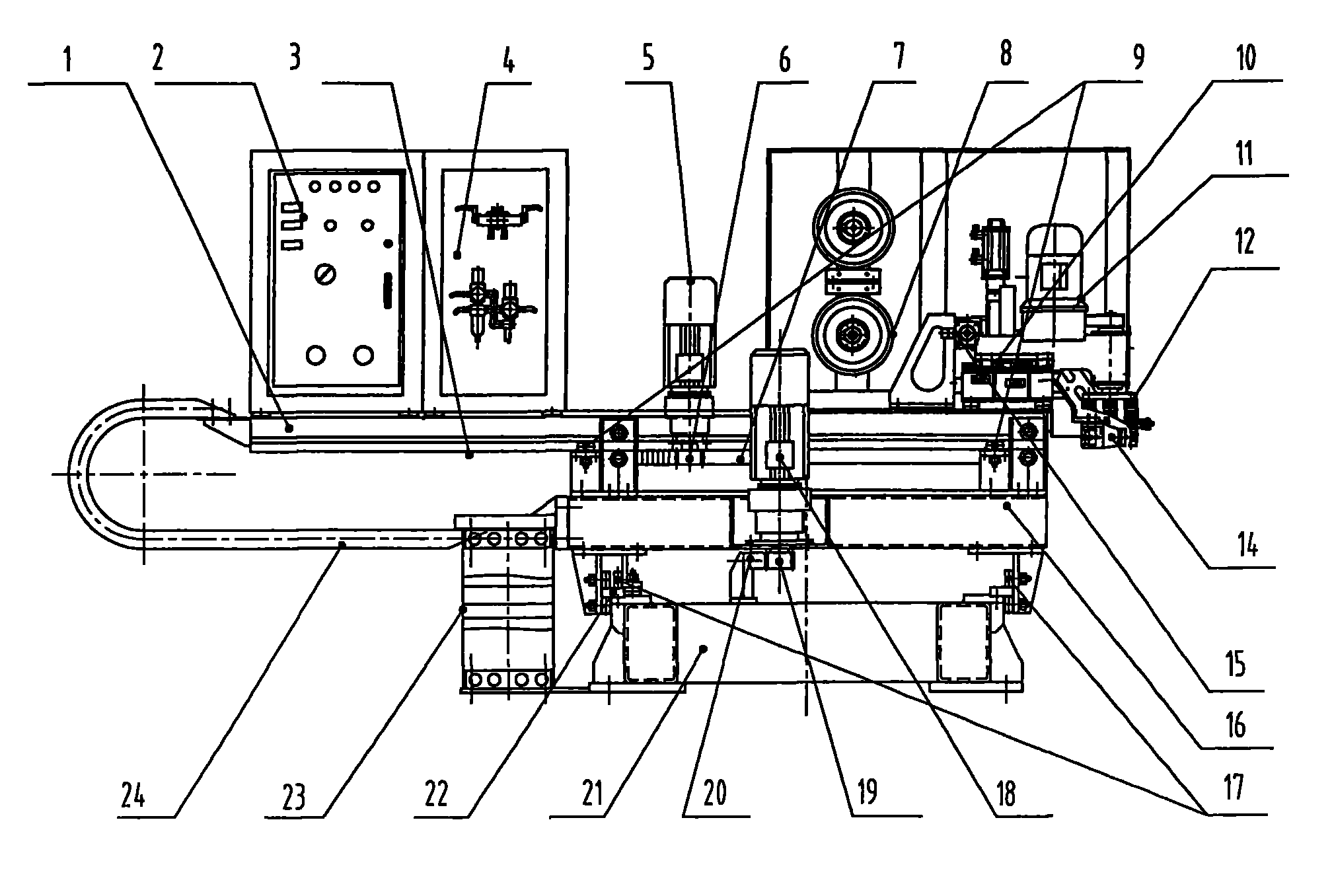

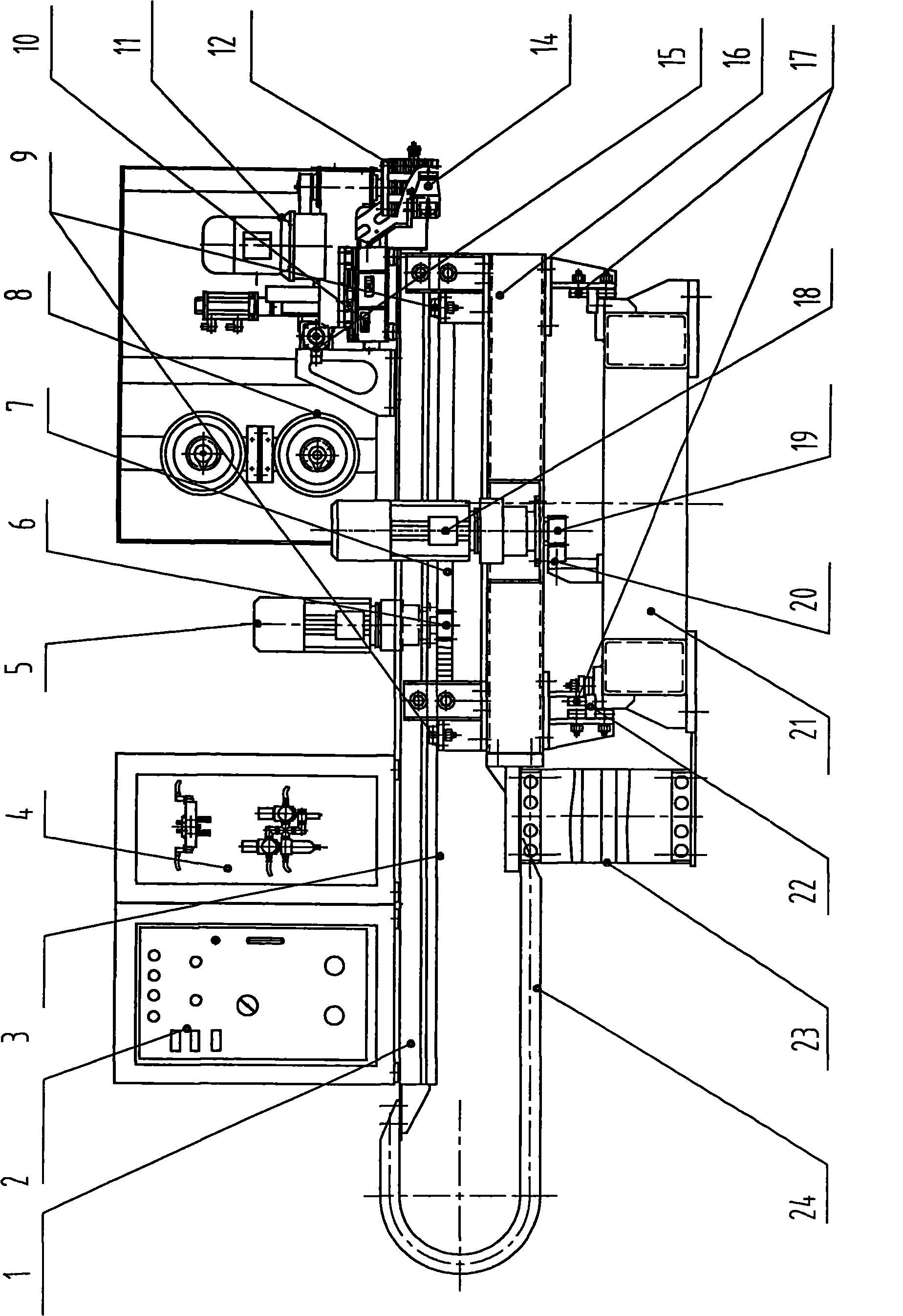

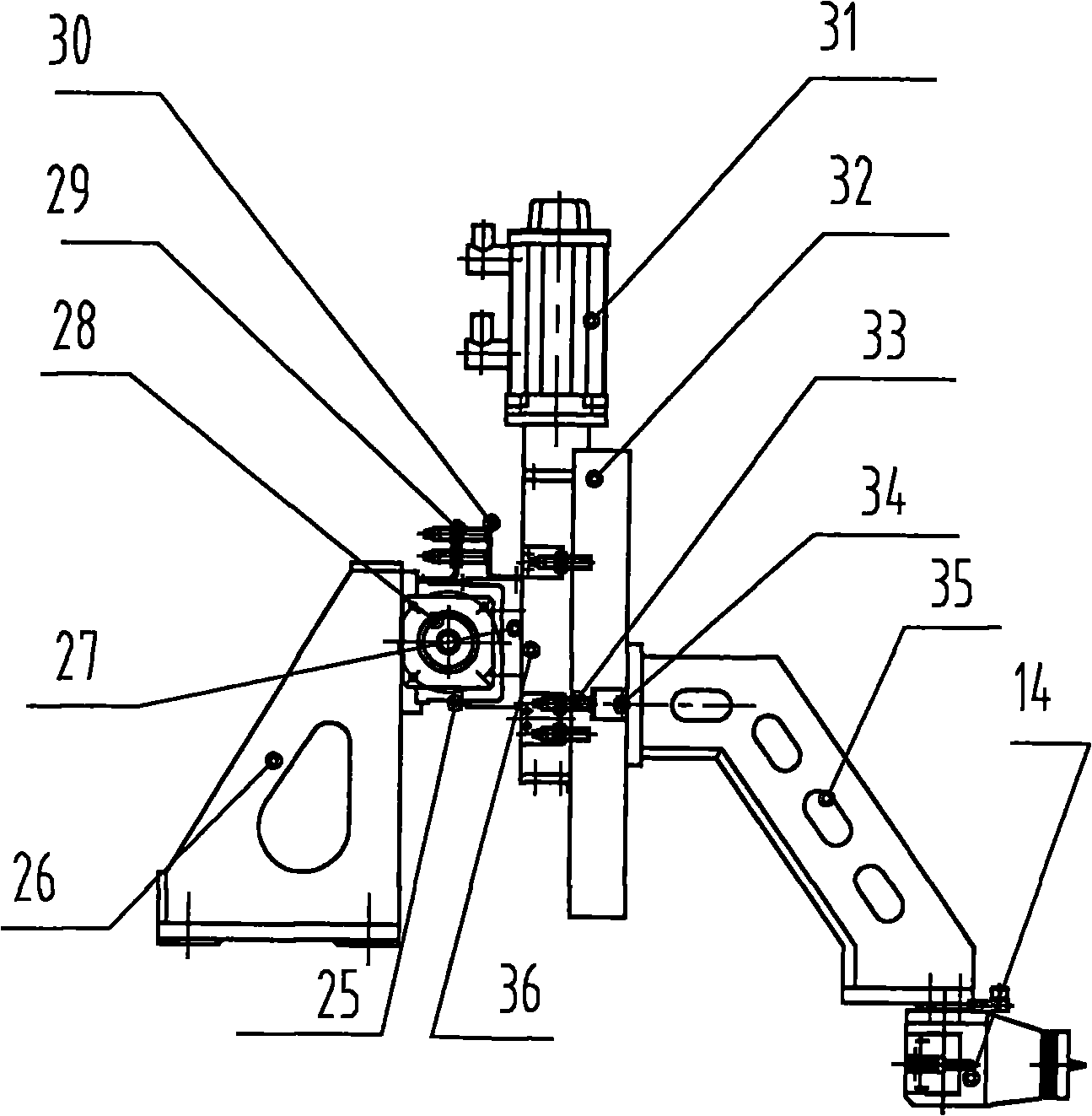

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] The invention includes a transverse movement mechanism, a longitudinal movement mechanism, an X / Y two-dimensional writing mechanism, an arc spraying system, a descaling mechanism and a pneumatic system; the base of the transverse movement mechanism is the installation basis of the equipment, and the longitudinal movement mechanism is installed on the On the vertical and horizontal moving support, the spraying power supply in the arc spraying system, the pneumatic system, the wire reel in the arc spraying system, the X / Y two-dimensional writing mechanism, and the descaling mechanism are installed on the vertical moving mechanism from left to right along the longitudinal drag chain. on the vertically movable support.

[0024] As shown in Figure 1, the described transverse mechanism: the transverse guide rail 22 and the transverse roller group 17 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com