Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, vehicle parts, etc., can solve the problems of unsatisfactory drainage, deterioration of handling stability, uneven wear, etc., and achieve good control. Stability, Maintaining Steering Stability, Ensuring Steering Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

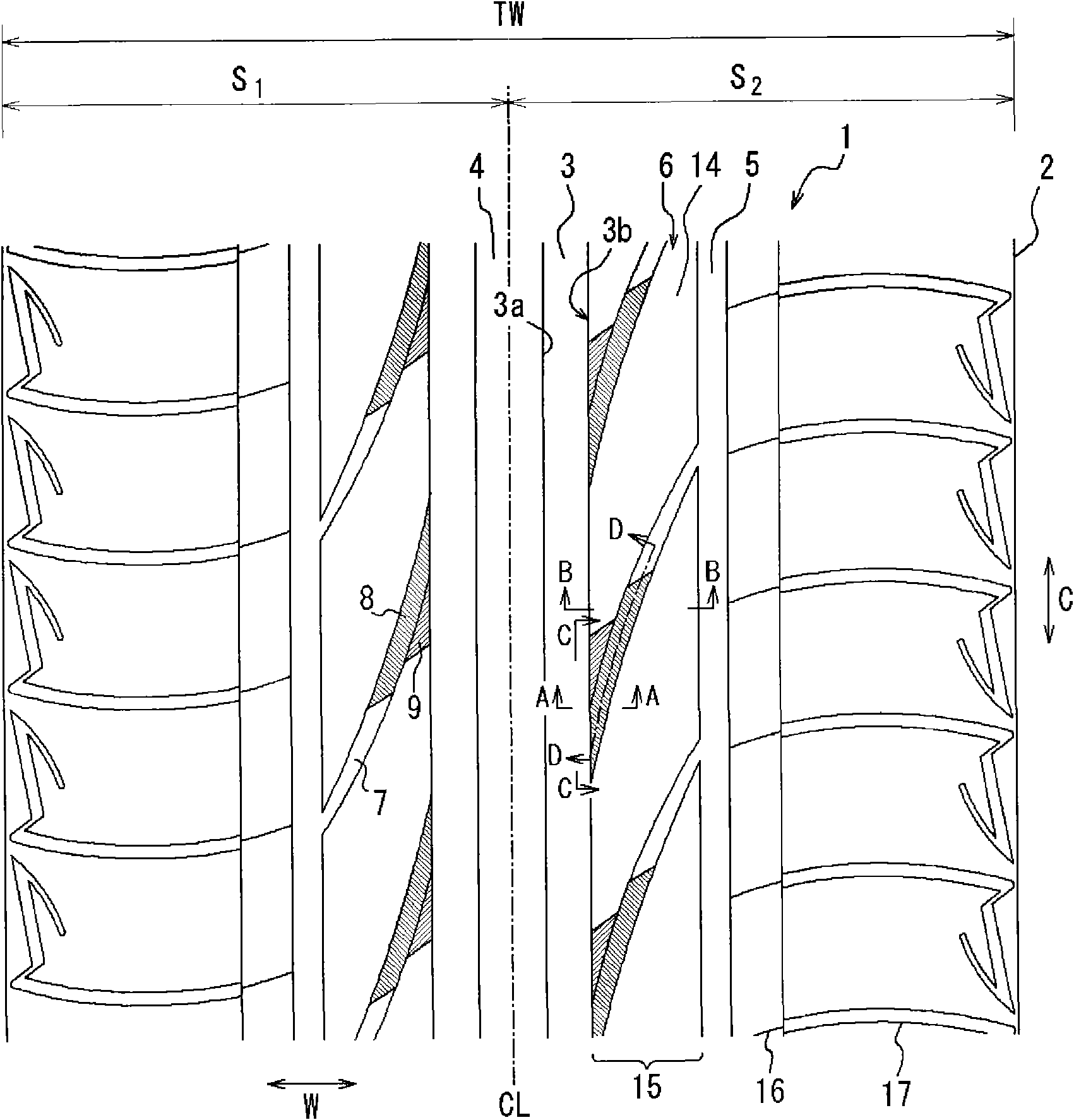

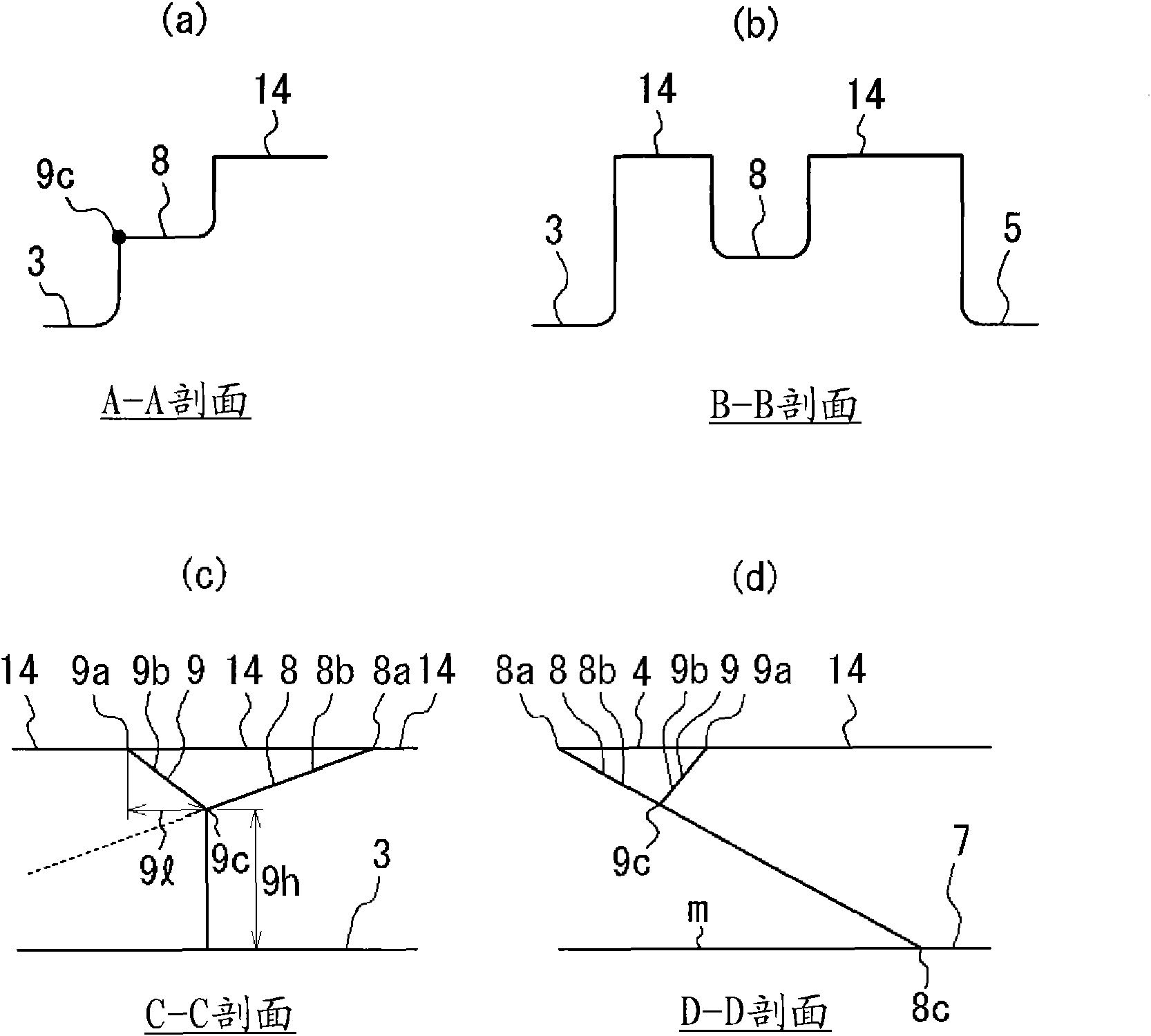

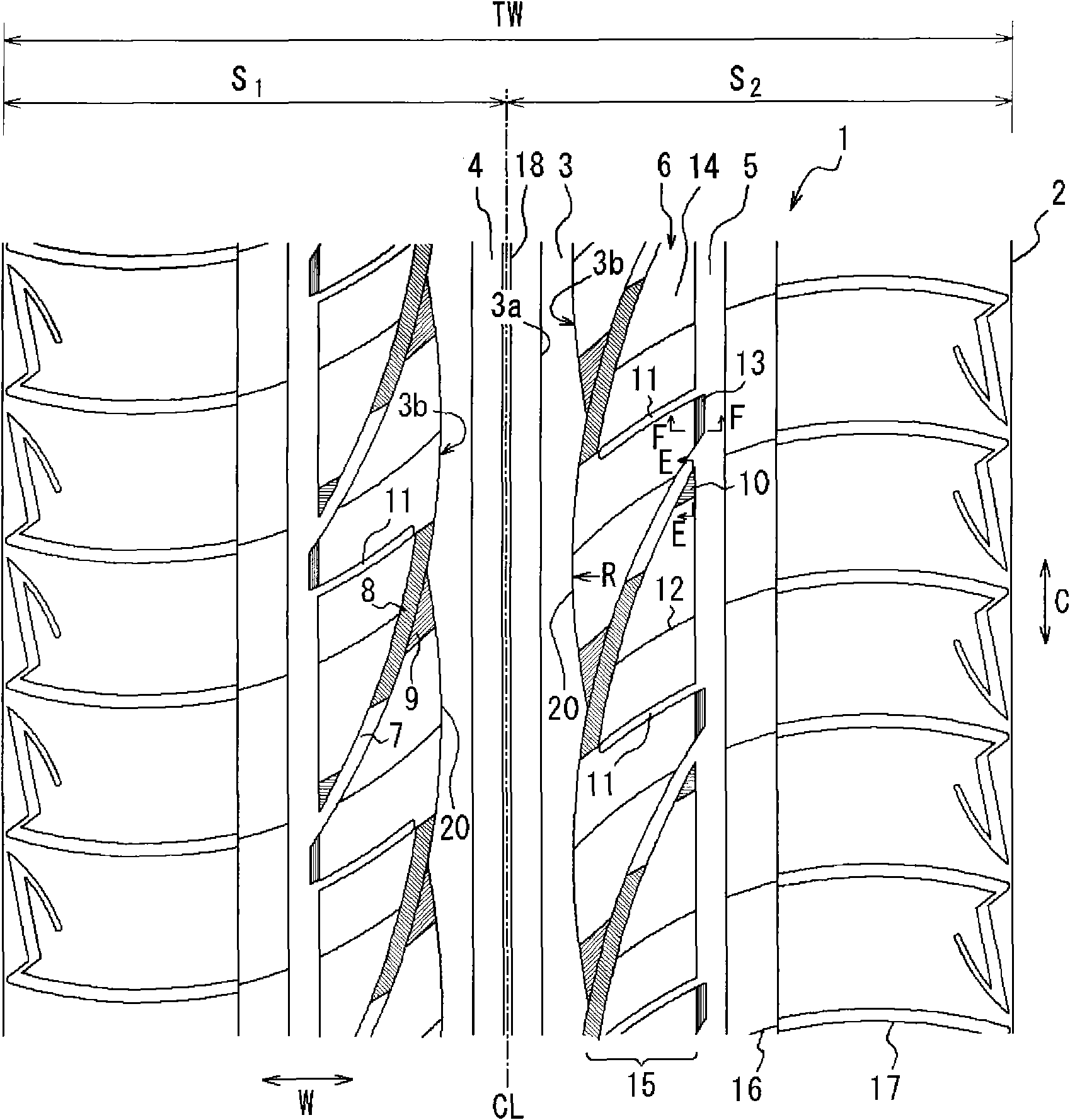

[0120] The tire of Example 1 has such image 3 The tread pattern shown, the sloping groove bottom 8 comprising flat sloping surfaces and as Figure 6 The first chamfer shown in (b), and the tire size of the tire is 195 / 65R15 (tread width TW is 150 mm). Tables 1 to 4 summarize details such as dimensions of the central main groove, side main grooves, steeply inclined grooves, gently inclined grooves, ribbed lands, blocks, etc.

[0121]Since the tire structure other than the tread portion does not need to be changed in the present invention, the tire structure of the tire of Example 1 other than the tread portion is substantially the same as that of a conventional pneumatic tire for passenger cars. The curvature radius R of each arc portion constituting the side wall of the land portion on the side of the central main groove was 165 mm (average).

[0122] Table 1

[0123]

[0124]

[0125] Table 2

[0126] Height of land part (mm)

The width of the land pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com