Method for eliminating heat exchanging corner and air condenser thereof

An air condenser and dead angle technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of not effectively improving the heat exchange capacity and efficiency at the dead ends of the heat exchange tubes, increasing investment costs and operating costs, and affecting environment and other issues, to achieve the effect of reducing investment costs, reducing operating costs, and improving air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A method for eliminating heat exchange dead ends and an air condenser of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

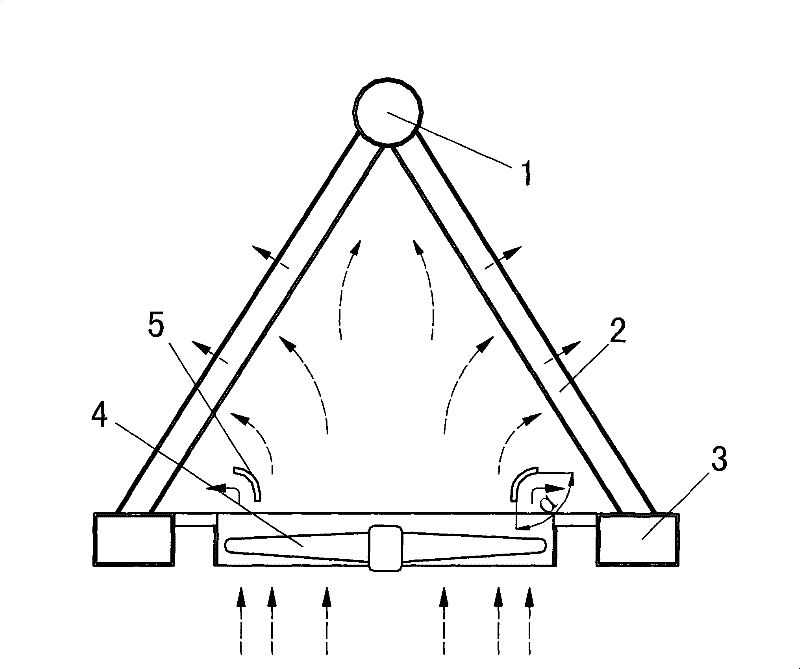

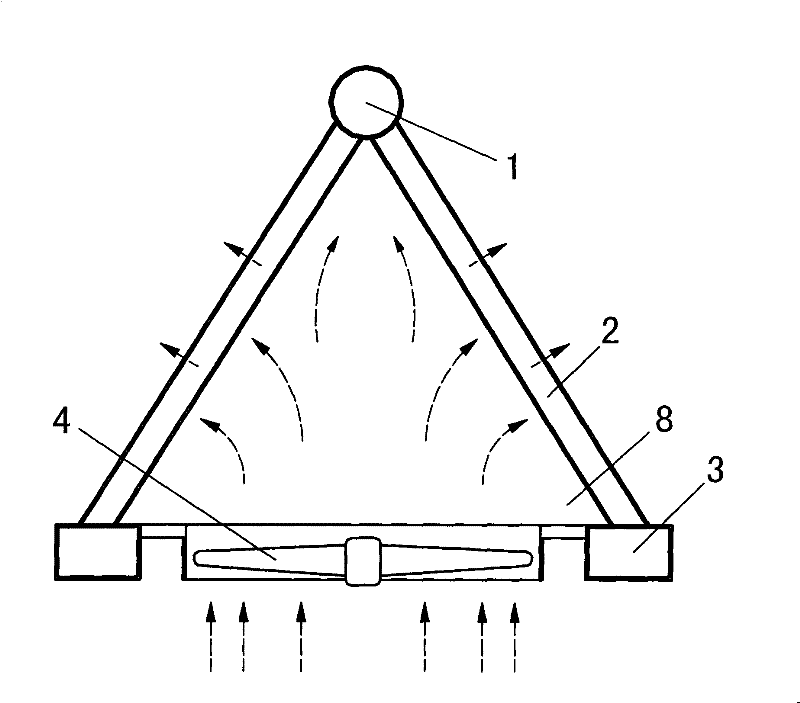

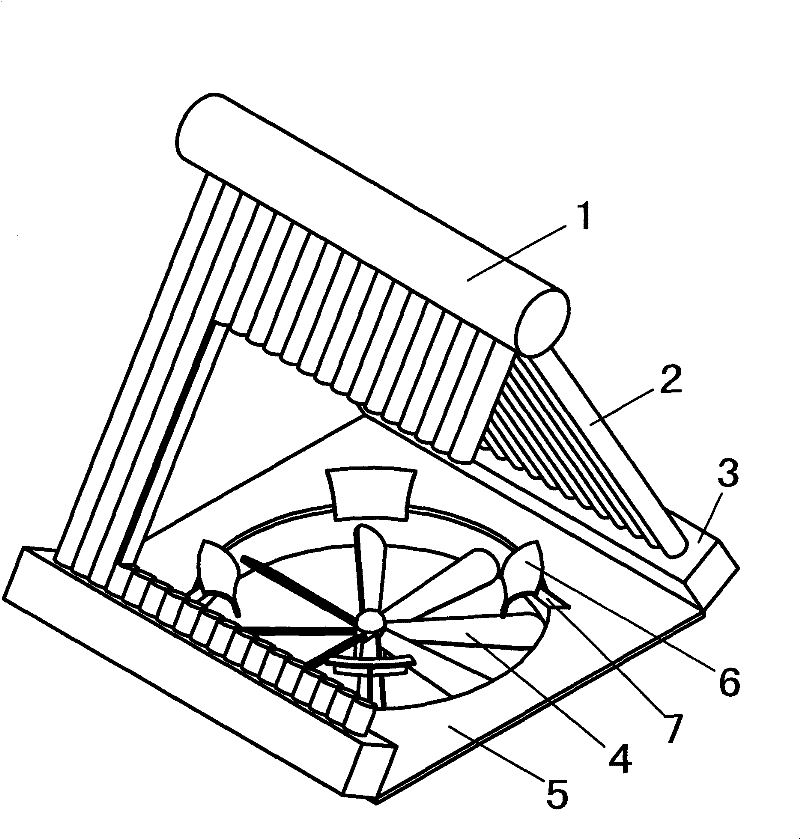

[0017] Example. The existing air condenser principle such as figure 2 as shown, figure 2 The direction of the arrow in indicates the direction of wind flow. From figure 2 It can be seen that there is a heat exchange dead angle 8 at the bottom of the heat exchange tube 2 . The method for eliminating the heat exchange dead angle of the present invention, such as figure 1 as shown, figure 1 The direction of the arrow in indicates the direction of wind flow. Depend on figure 1 It can be seen that because a group of guide plates 5 are set at the air outlet of the axial flow fan 4, the wind direction changes after the wind meets the guide plates 5, and the guide angle of the guide plates is 80-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com