Temperature control system and temperature control method of machine cabinet

A temperature control system and cabinet technology, applied in ventilation systems, heating methods, lighting and heating equipment, etc., can solve the problems of large impact on heat dissipation efficiency, equipment overcooling, condensation in the inner cavity, etc., to achieve a wide range of temperature adaptation, heat dissipation High reliability and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

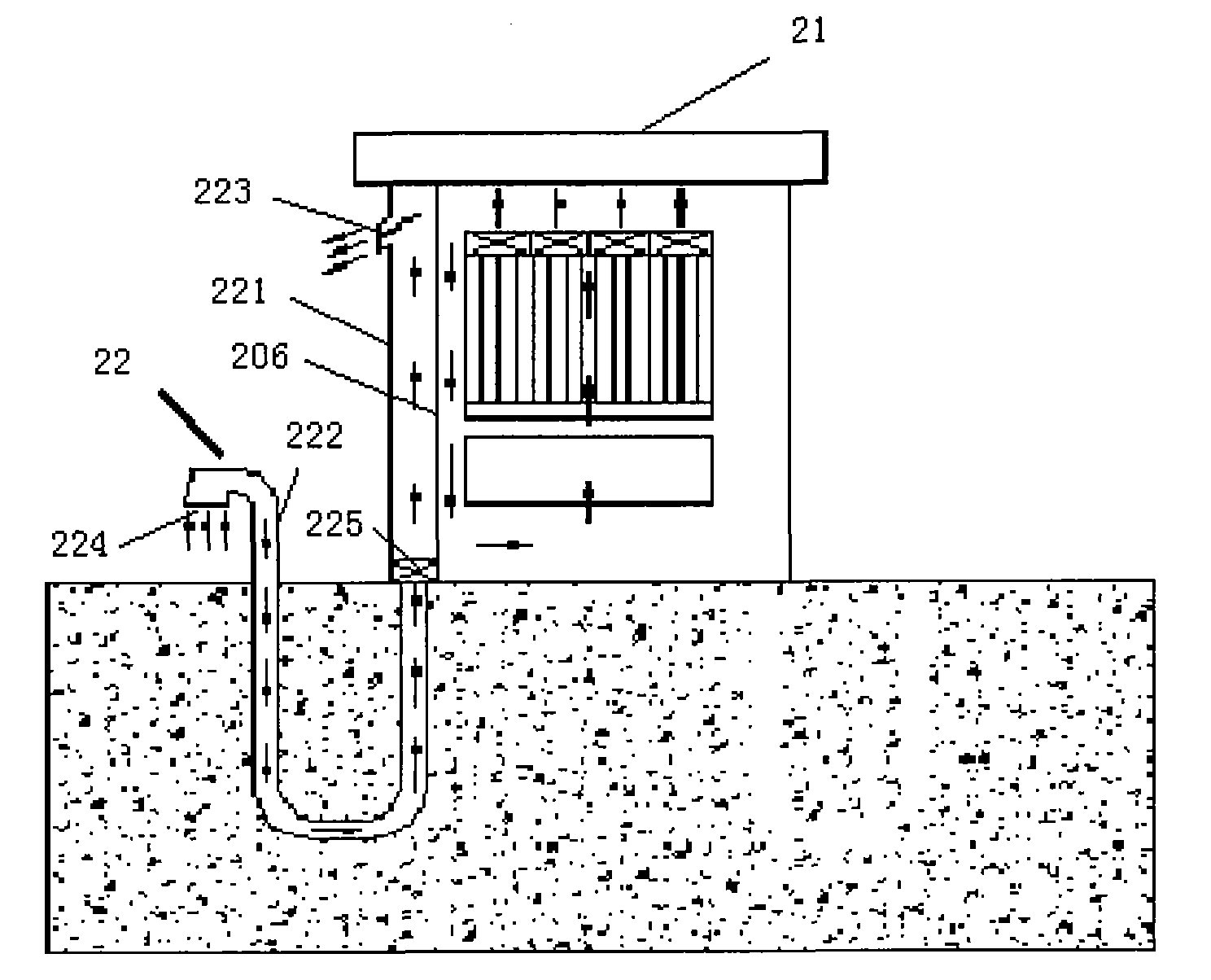

[0027] refer to figure 2 As shown, the cabinet temperature control system of the first embodiment of the present invention includes: a cabinet 21 and a heat dissipation pipeline 22 that communicates with the cabinet and runs through the ground.

[0028] A sealed internal circulation cavity is formed inside the cabinet 21, and the internal circulation is formed by the air drive system of the equipment in the cabinet itself. The circulation cavity in the cabinet is completely sealed, which is beneficial to dustproof, waterproof and humidity control.

[0029] The heat dissipation pipeline 22 includes a first pipeline 221 located in the cabinet and a second pipeline 222 buried underground; the first pipeline includes an air outlet 223 located at the upper part of the cabinet and communicated with ambient air ; The second pipeline includes an air inlet 224 communicating with ambient air. The inner wall of the first pipeline is a heat exchange wall 206, and the outer circulation ...

Embodiment 2

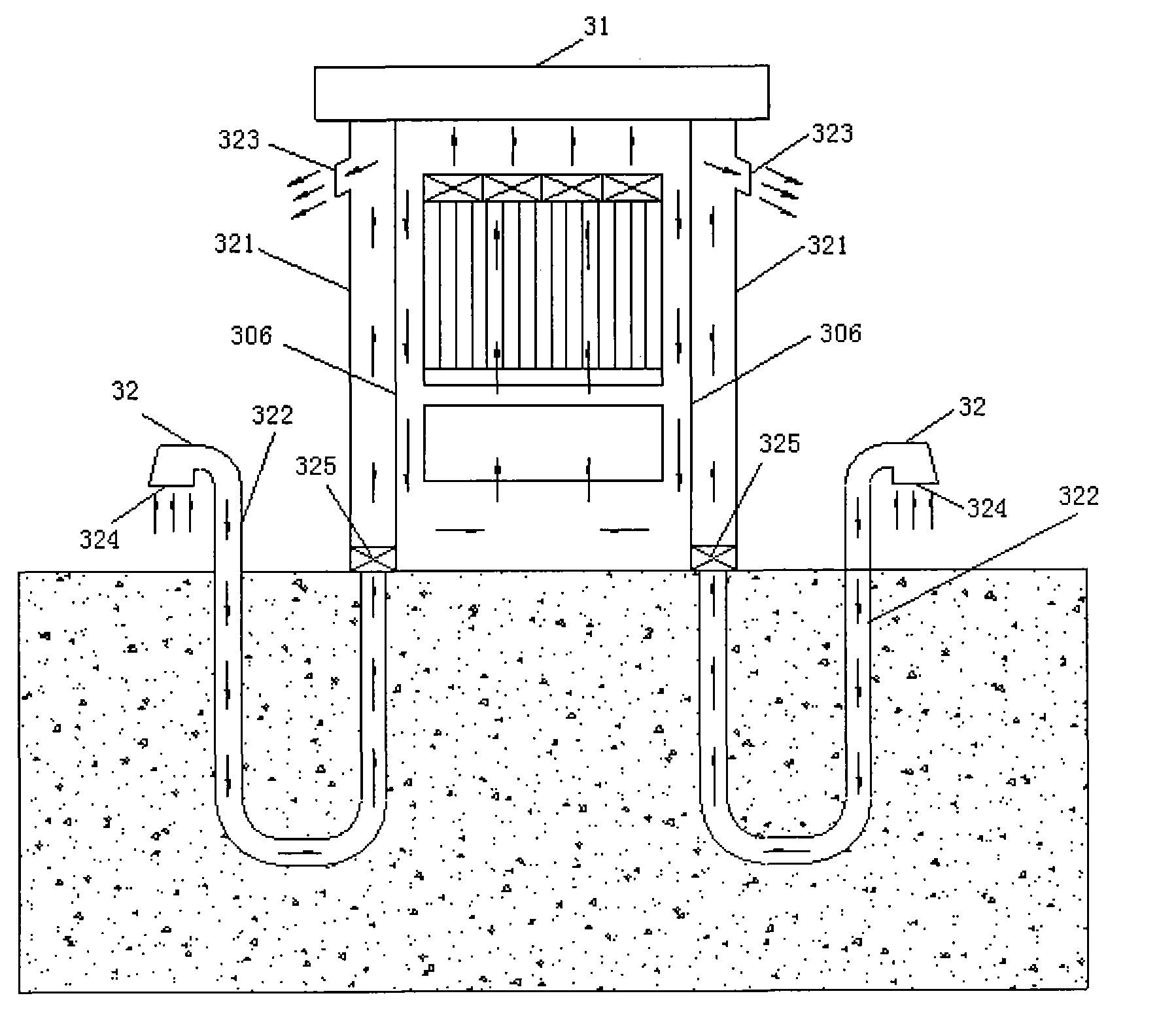

[0040] Such as image 3 As shown, the cabinet temperature control system in the embodiment of the present invention includes a cabinet 31 and two temperature control heat dissipation pipelines 32 that communicate with the cabinet and run through the ground.

[0041] A sealed internal circulation chamber is formed inside the cabinet 31, and the internal circulation is formed by the air drive system of the equipment in the cabinet itself. The circulation cavity in the cabinet is completely sealed, which is beneficial to dustproof, waterproof and humidity control.

[0042] The two heat dissipation pipelines 32 are arranged on the left and right sides of the cabinet respectively; each heat dissipation pipeline 32 includes a first pipeline 321 located in the cabinet and a second pipeline 322 buried underground; the first pipeline The path 321 includes an air outlet 323 located at the upper part of the cabinet and communicates with the ambient air; the second pipeline includes an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com