Direct-drive oil parallel sewing machine

A technology of lockstitch sewing machines and couplings, which is applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., which can solve the problems that the outer circle is not closed, easily deformed, and affects sewing performance, so as to ensure sewing performance and ensure The effect of connection rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

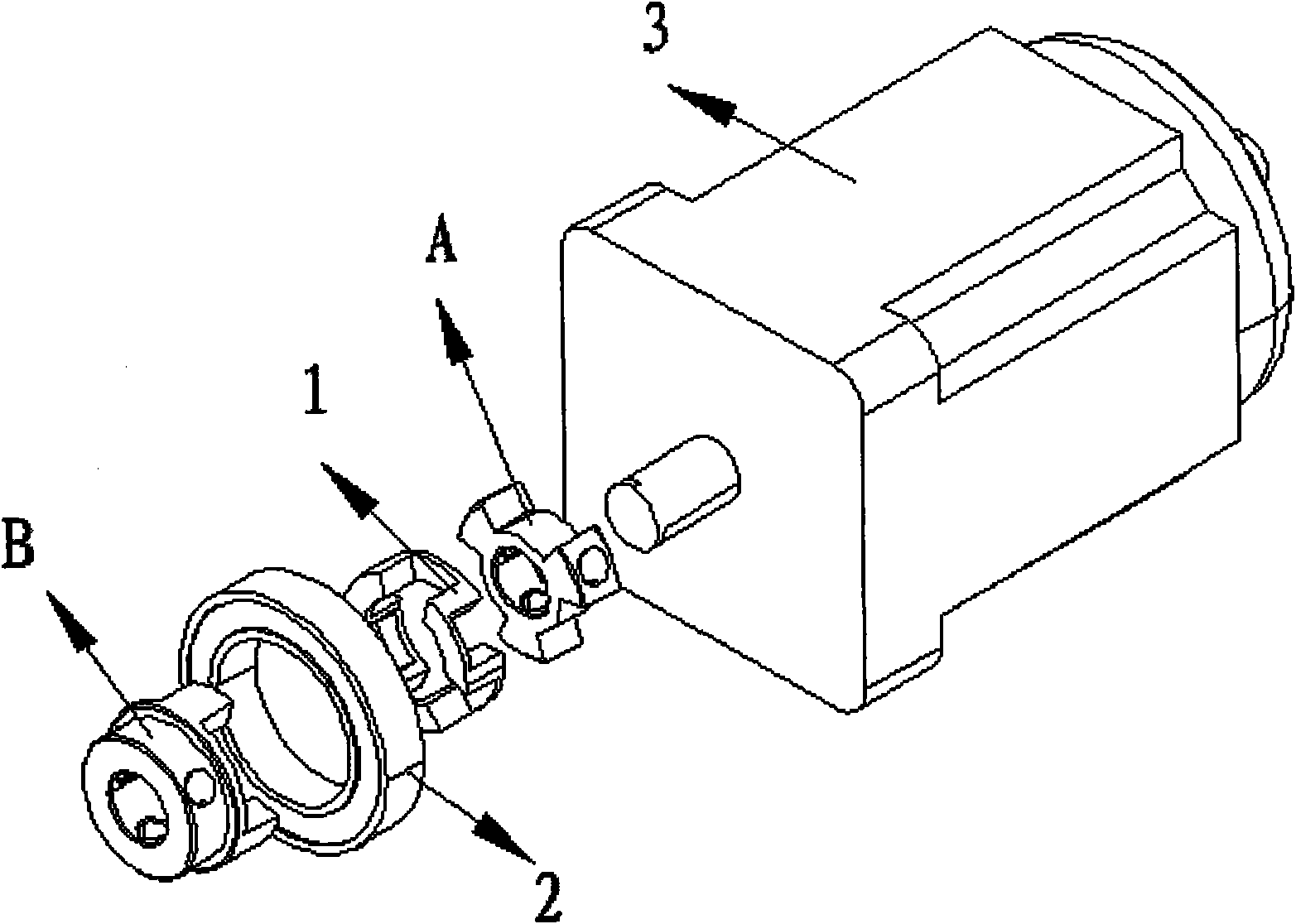

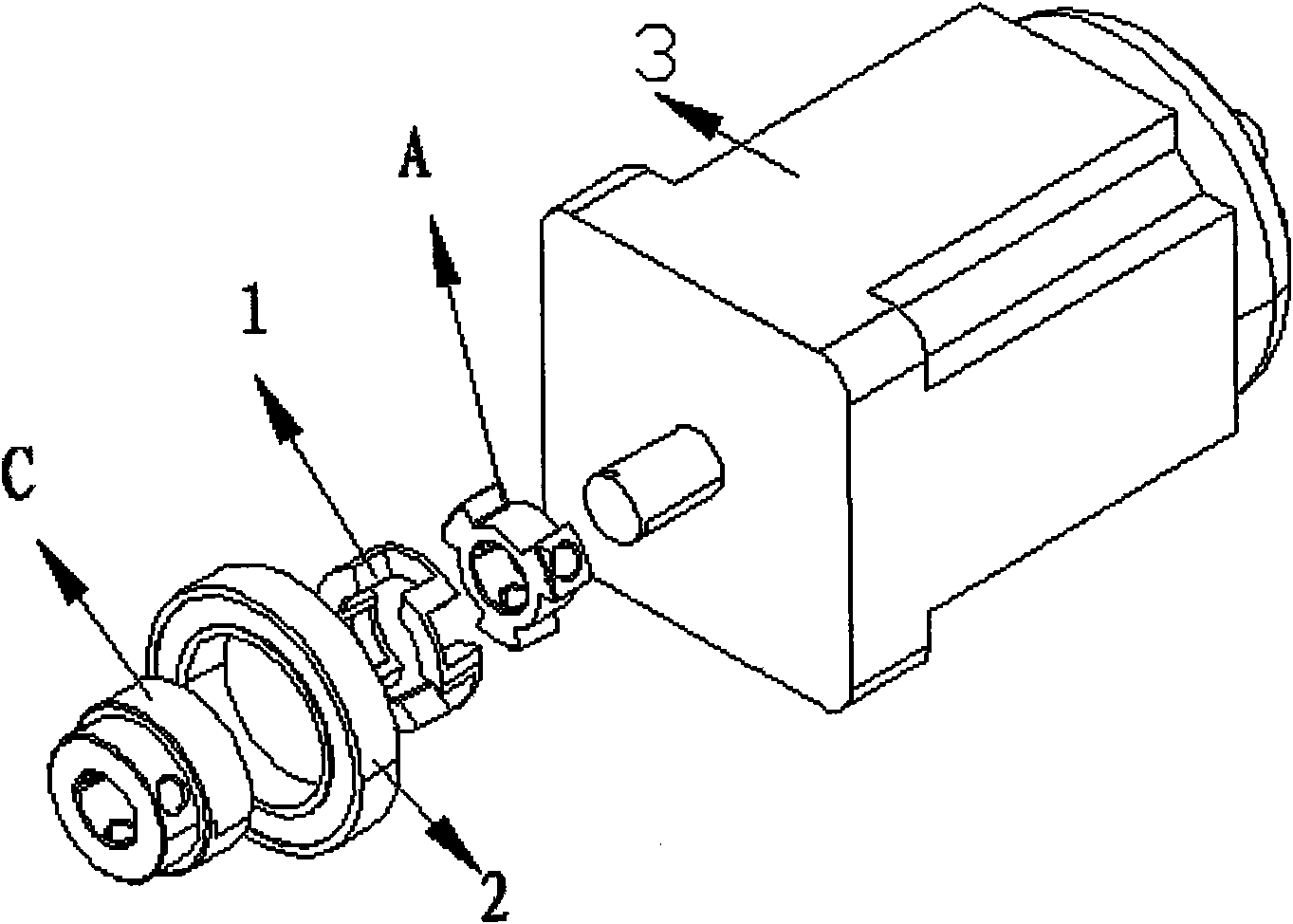

[0012] Depend on figure 2 It can be seen that the present invention includes: motor 3, bearing 2; also includes: first coupling A, coupling rubber 1, and second coupling C between the motor 3 and bearing 2; the first coupling The shaft joint A is connected with the shaft of the motor 3, and on the outer side of the first joint joint A are the joint joint rubber 1 and the second joint joint C; The outer circle around the rubber 1 is a closed ring structure.

[0013] The outer circle of the shaft coupling C in the present invention has been changed into a whole, and no deformation will occur in the process of pressing into the bearing, so that the rigidity is improved, and there will be no relative rotation between the two; due to the adoption of this The structure ensures the rigidity of the connection and indirectly guarantees the sewing perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com