Assembly technique for head sealing cover and kettle of stock solution crystallizer

An assembly process and crystallizer technology, applied in the direction of solution crystallization, etc., can solve the problems of adverse effects of head cover joints or pipe joints, large cracks, and poor fit, etc., to shorten the assembly period, reduce the manufacturing cost, and simplify the operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

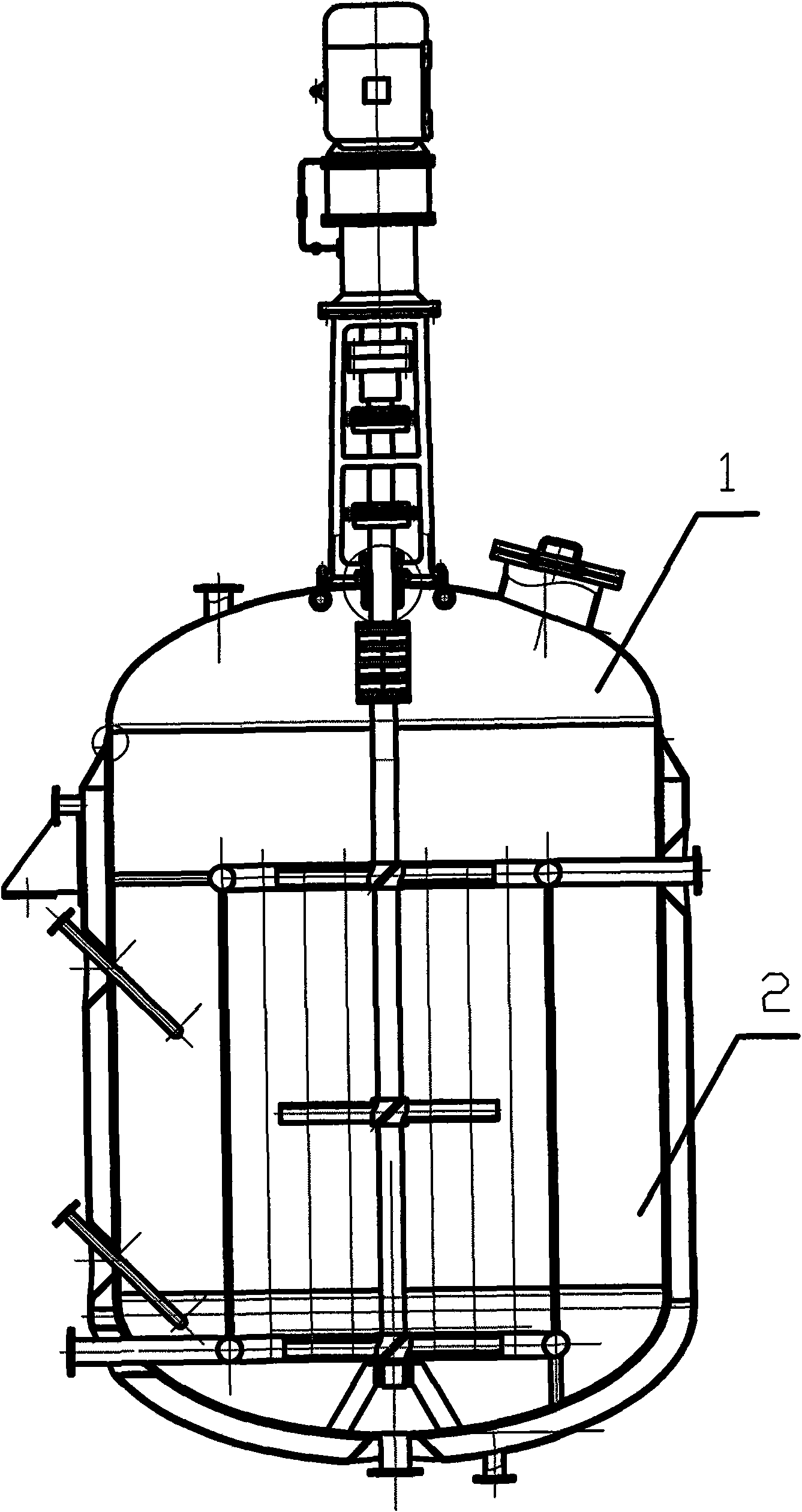

Image

Examples

Embodiment Construction

[0015] The method for assembling the head cover and the still body of the stock liquid crystallizer of the present invention comprises the following steps:

[0016] 1. Make the head cover according to the process requirements;

[0017] 2. According to the shape of the head cover and the arrangement position of the joints or pipe joints on the head cover, make an assembly pallet, and put the head cover upside down on the assembly pallet;

[0018] 3. Make the kettle body composed of inner and outer cylinders according to the process requirements, lift the kettle body with lifting tools, and place the kettle body upside down on the head cover;

[0019] 4. Adjust the position of the kettle body, and rely on the self-weight of the kettle body to make the contact between the kettle body and the head cover fit tightly;

[0020] 5. Welding is carried out according to the process requirements, so that the head cover and the kettle body are connected into one.

[0021] In the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com