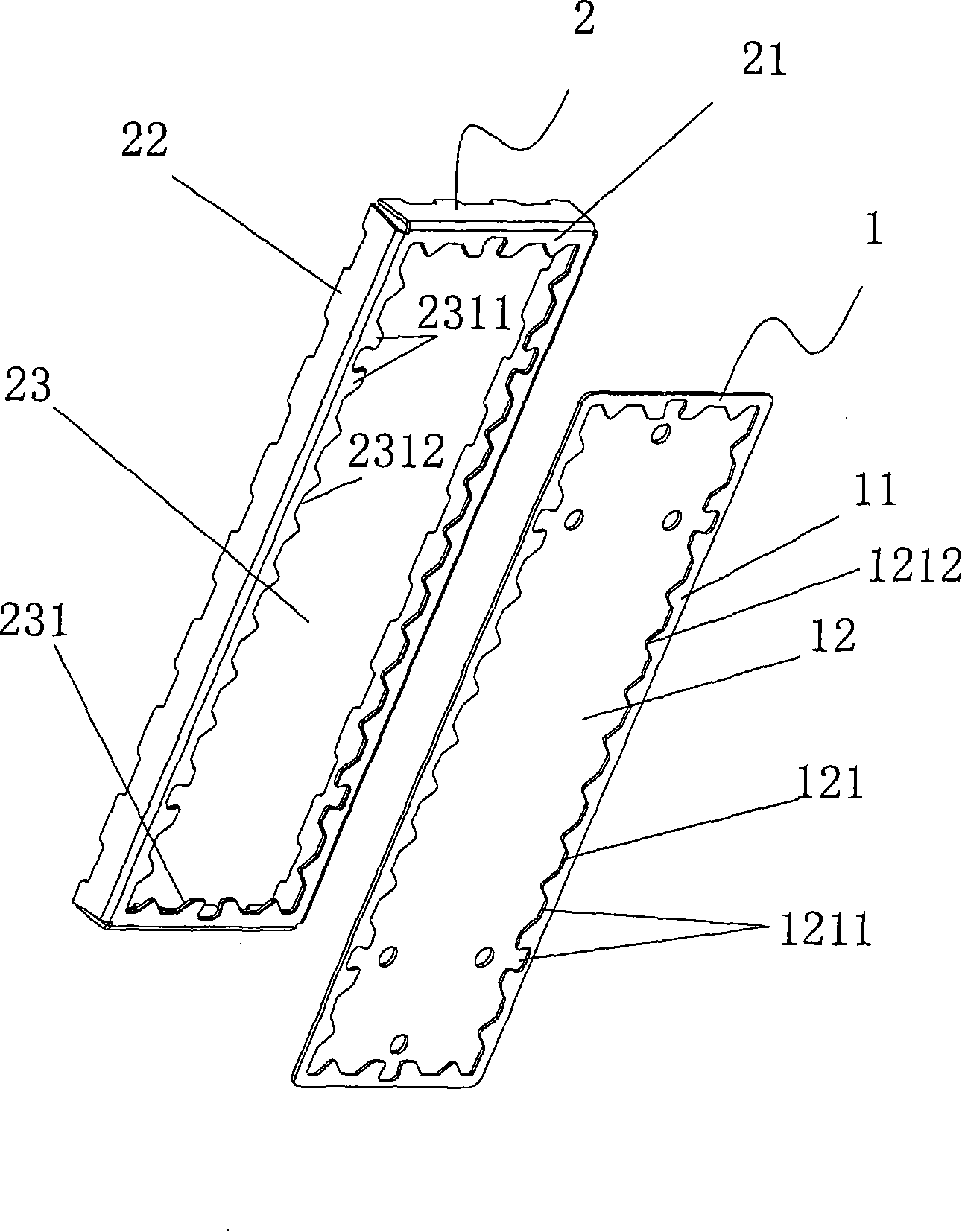

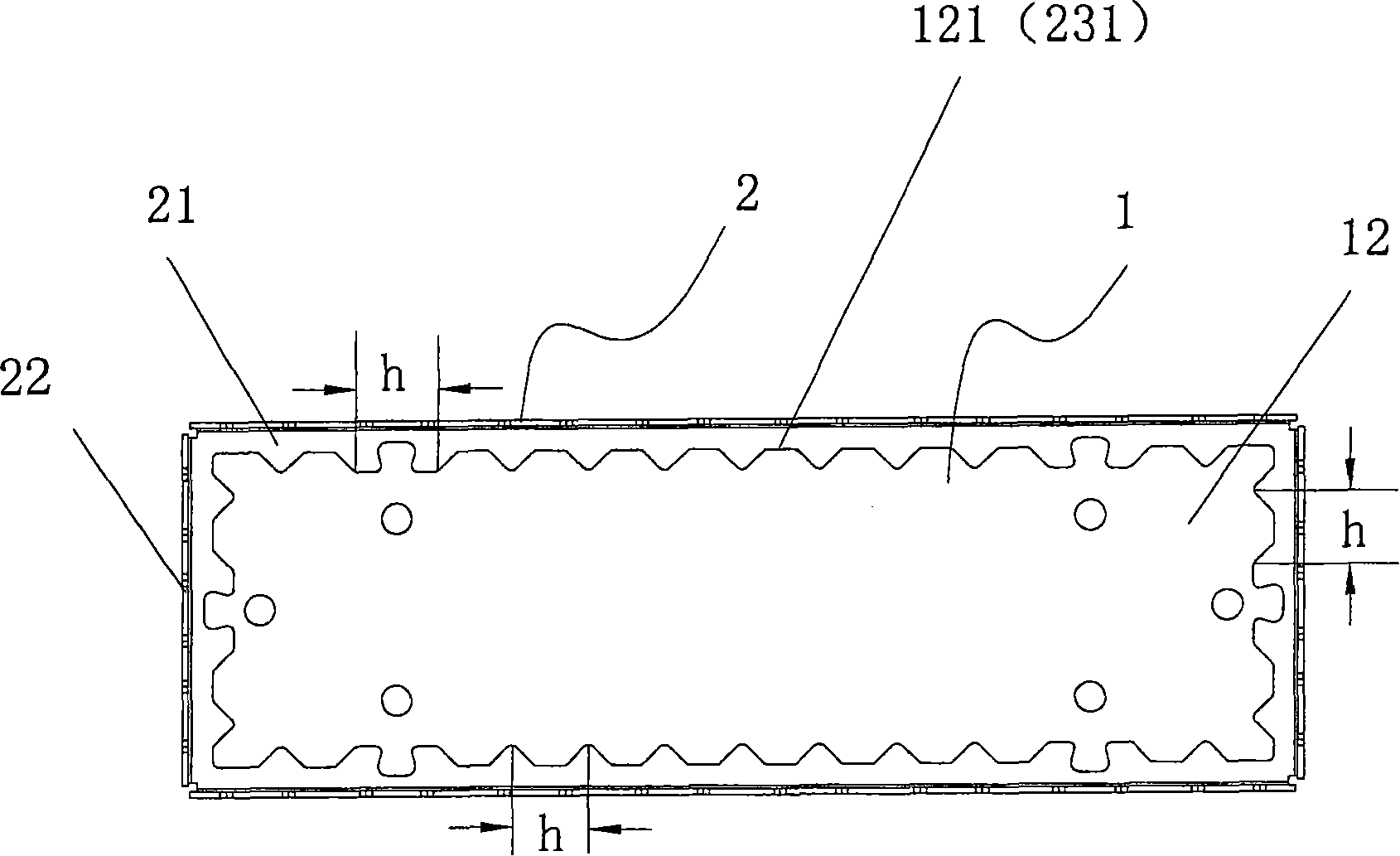

Shielding device and manufacturing method thereof

A technology of shielding device and manufacturing method, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve problems such as difficult to cooperate well, increase assembly clearance, occupy side space of shielding cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The details of the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, it should be noted that the following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or use of the present invention.

[0033] In the description, certain terms used herein are for reference only, and therefore are not meant to be limiting. For example, terms such as "upper", "lower", "above", "below", "top" and "bottom" refer to directions in the drawings to which reference is made. Terms such as "front", "backward", "rear", "bottom" and "side" describe the orientation of each part of a component in a consistent and arbitrary frame of reference, and describe the component in question by contrast The text and related drawings can make this frame of reference clear. Such terms may include the words exactly described above, their derivatives, and words with similar mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com