Sewing machine

A sewing machine and machine frame technology, which is applied to sewing machine components, sewing machine needle holders, sewing equipment, etc., can solve problems such as increased resistance, embroidery pattern damage, and difficulty in stabilizing immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

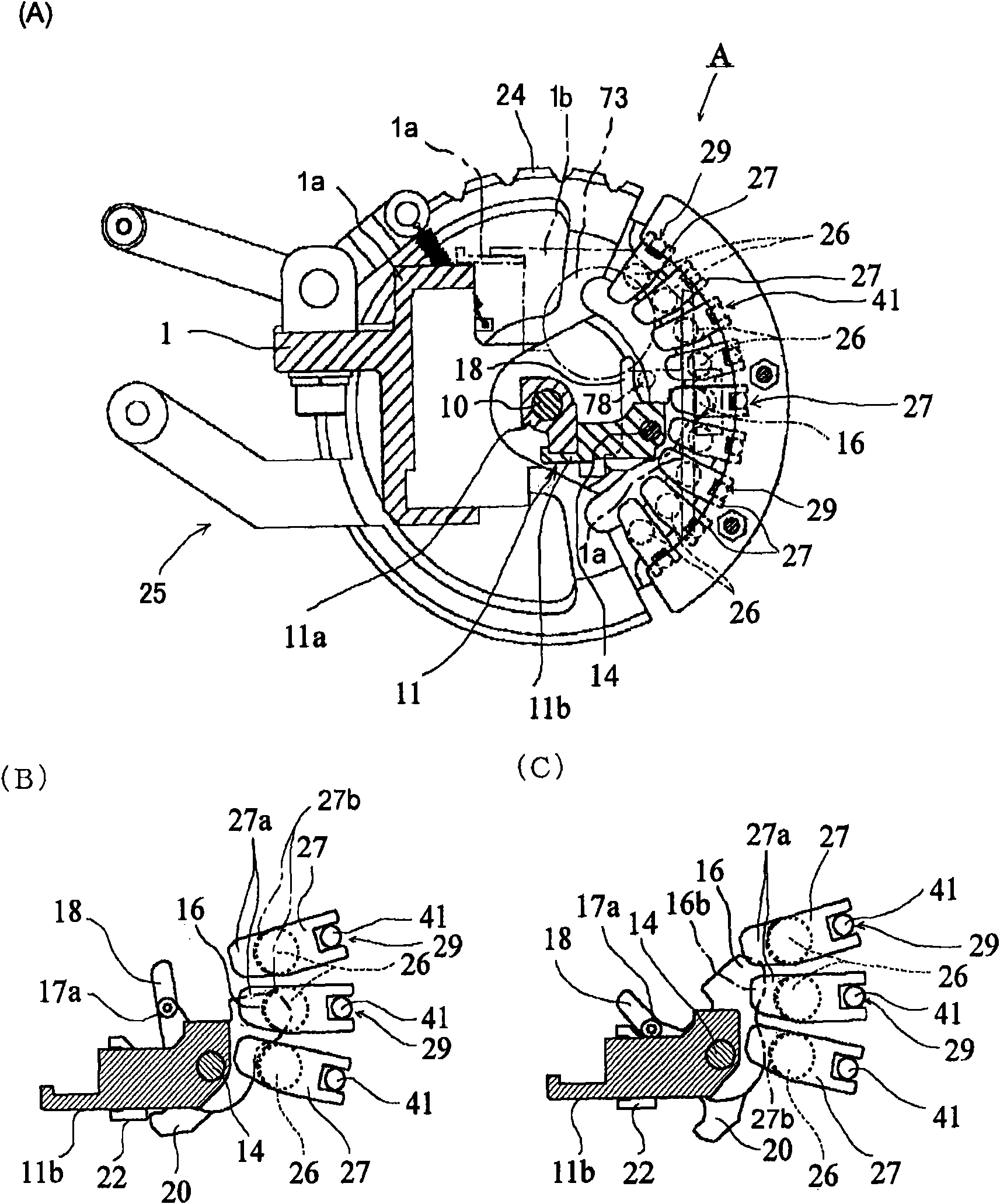

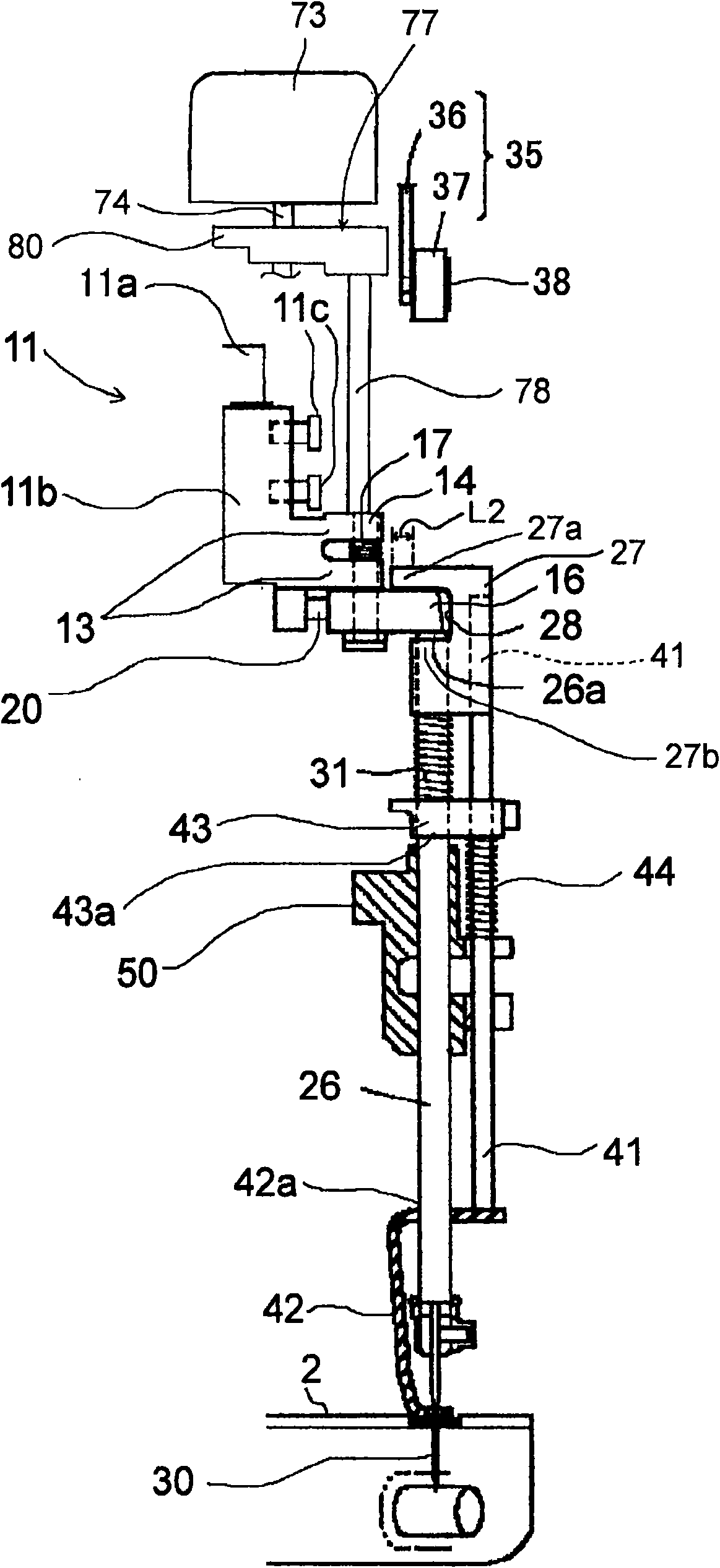

[0054] Embodiments of the present invention will be described below using the drawings. exist figure 1 , figure 2 Among them, frame 1, thread take-up lever 3, parts 24-31 related to the needle bar, parts 35-38 related to the needle bar stopper, parts 41-44 related to the cloth presser foot, parts related to the lifting body Parts 5-22, parts related to the jump mechanism 70 (however, the novelties added in the following explanations related to parts such as the hooking part 27 of the needle bar, the second engaging claw 16b of the lifting body, and the action part 78 The configuration of the technical solution (component configuration, combination and function, etc.) except for the description of related matters) represents an example of the component configuration of a conventionally known known sewing machine. figure 1 An example of the same operation and function as the sewing machine shown in .

[0055] Reference numeral 1 denotes a frame (also referred to as a bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com