Bidirectional choke plug

A plug and closed structure technology, applied in the direction of pipes/pipe joints/fittings, pipe components, valve details, etc., can solve problems such as hydraulic oil leakage, and achieve the effect of convenient production, no need to disassemble pipelines, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

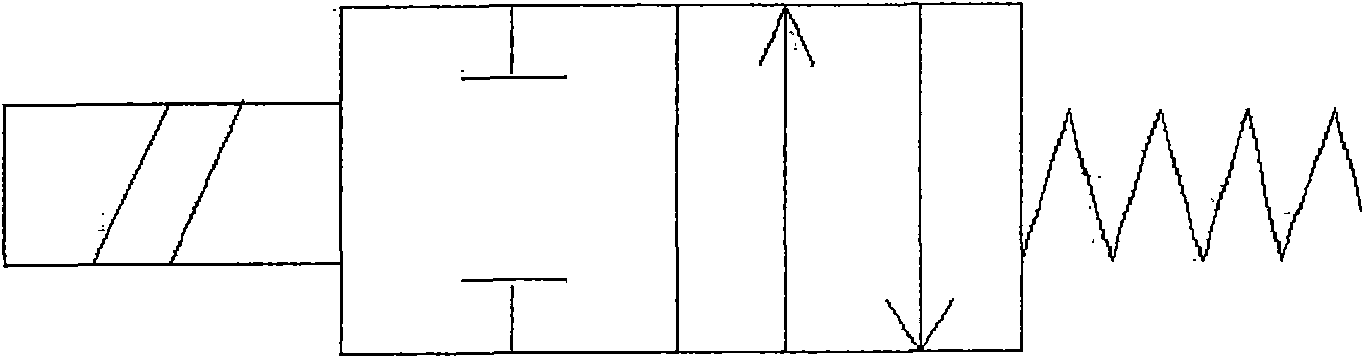

[0047] A common two-way plug, such as figure 2 As shown, the two ends connected with the oil pipe can be threaded, or can be ferrule type, flared sleeve, flared nut and other types like ordinary pipe joints, and the middle part is set as a closed structure.

[0048] An electronically controlled two-way plug, such as image 3 As shown, it is a 2-position, 2-way solenoid valve, and the opening and closing of the plug can be controlled by electrical signals.

[0049] The above-mentioned two-way plugs can be applied to hydraulic system debugging. Electronically controlled two-way plugs with automatic intermediate sealing function are installed at each key component of the hydraulic system, and the hydraulic system is debugged by turning on and off the state of the electronically controlled two-way plugs. When working normally, the two-way plug i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com