Gearbox for a motor vehicle

A technology for gearboxes and motor vehicles, applied in the field of gearboxes, can solve problems such as intensification, large space, occupation, etc., and achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

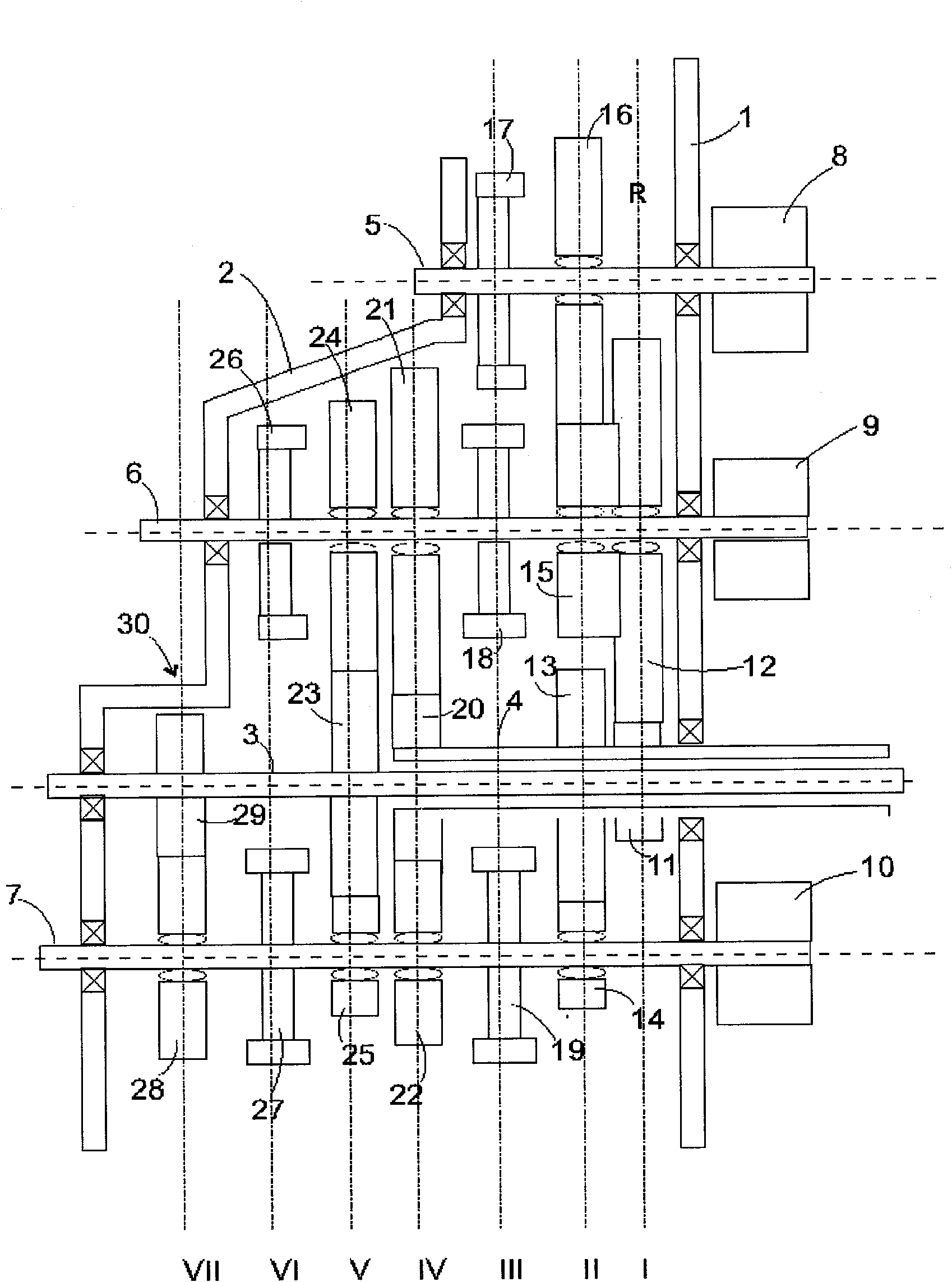

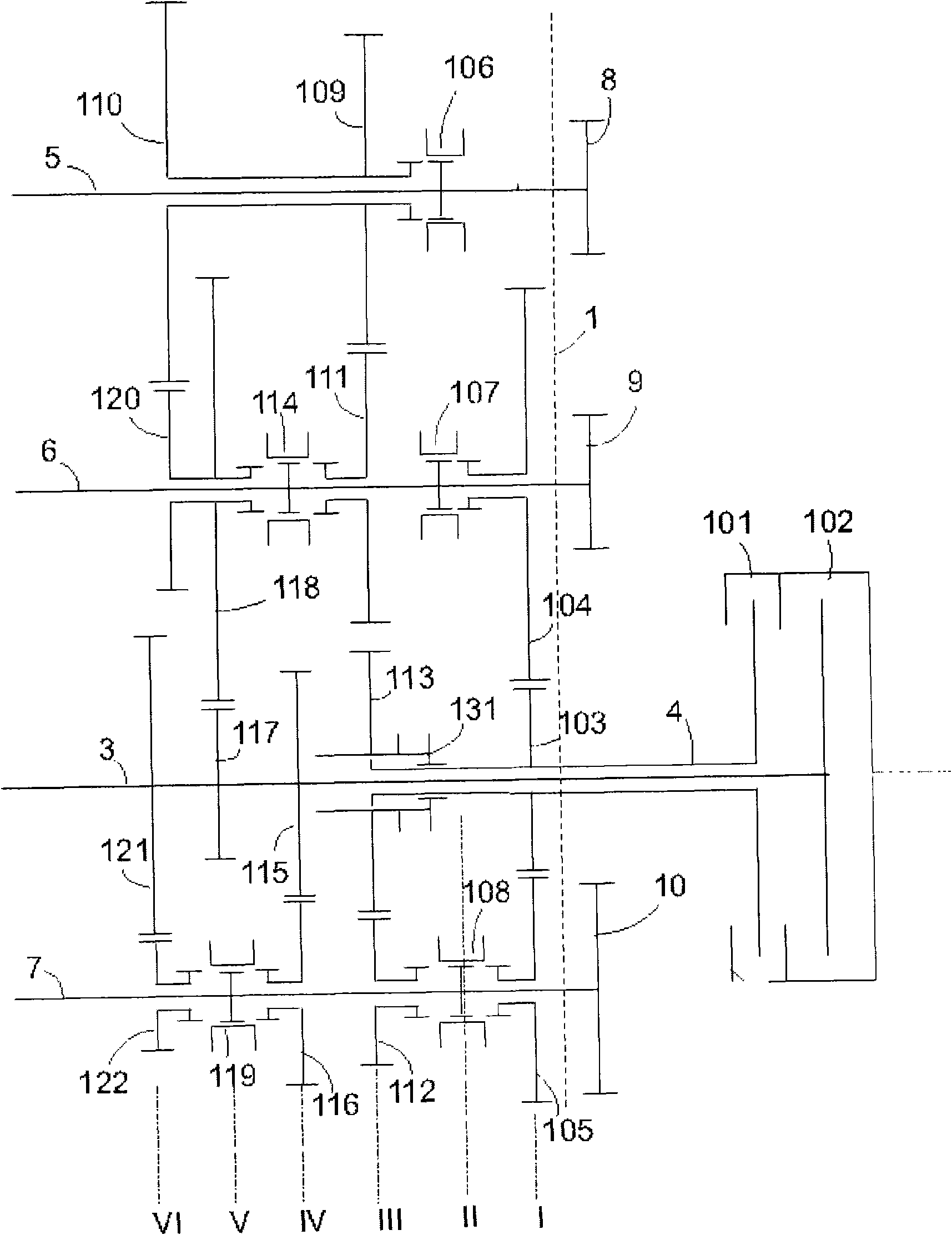

[0044] figure 1 The gearbox shown has a housing whose front and rear walls 1, 2 are shown in the figure. The front wall 1 faces a not shown double clutch, by means of which a solid input shaft 3 or a hollow input shaft 4 extending coaxially along the solid input shaft 3 is selectively driven. The secondary shafts 5 , 6 , 7 are rotatably supported in the walls 1 , 2 . Each layshaft extends partly from the gearbox, over the front wall 1, and carries a pinion 8, 9, 10 respectively. All three pinions 8, 9, 10 mesh with the same output differential not shown.

[0045] On the inside of the gearbox housing, immediately adjacent to the plane I of the front wall 1 , a gear wheel 11 is mounted in a torque-proof manner on the input shaft 4 . Gear 11 drives in rotation a gear 12 mounted on layshaft 6 . Gear 11 is the smallest of all the gears in the gearbox, while gear 12 is the largest.

[0046] On the second plane II of the gearbox, next to the plane I of the gears 11, 12, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com