Integral truss-type offshore wind turbine support structure

A support structure and offshore wind power technology, applied in wind turbine components, wind turbines consistent with the wind direction, wind power generation, etc., can solve the problem of high stress concentration at the connection between the central column and other rods, and vortex induced by cylindrical towers. Problems such as vibration and stress concentration are outstanding, and the effects of rational distribution of stiffness and strength, reduction of stress concentration and fatigue damage rate, and low construction cost are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

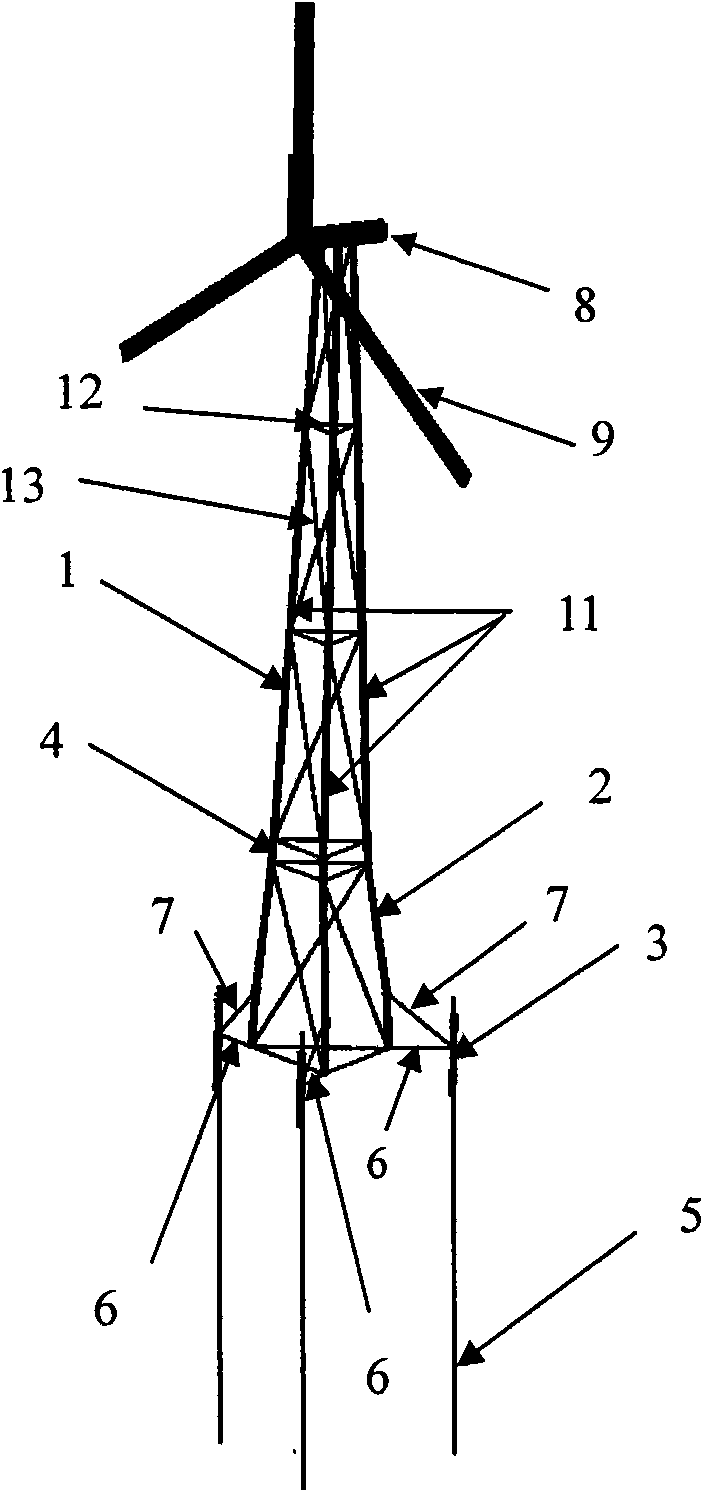

[0033] figure 1 It is a structural schematic diagram of the overall truss-type offshore wind turbine support structure according to the present invention, including three piles 5, and is characterized in that: it also includes a truss-type wind turbine tower 1, a truss-type foundation structure 2, a truss-type wind turbine tower 1, and a truss The basic structure 2 consists of three columns 11 arranged in an equilateral triangle to form an outer frame, and several horizontal struts 12 and diagonal struts 13 are arranged between the columns 11; the truss-type fan tower 1 and the truss-type foundation The flange 4 is connected; the lower end of each column 11 of the truss foundation structure 2 is provided with a leg 3, and the pile leg 3 is connected with the column 11 of the truss foundation structure 2 through the connecting rod A6 and the connecting rod B7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com