Deep cavity quartz crucible with the thick wall of 26 inches, production method and equipment thereof

A quartz crucible and crucible technology, applied in the 26-inch thick-walled quartz crucible, its production method and production equipment field, can solve the problems of long service life, large volume when melting materials, inability to manufacture thick walls, etc. Uniform wall thickness and good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

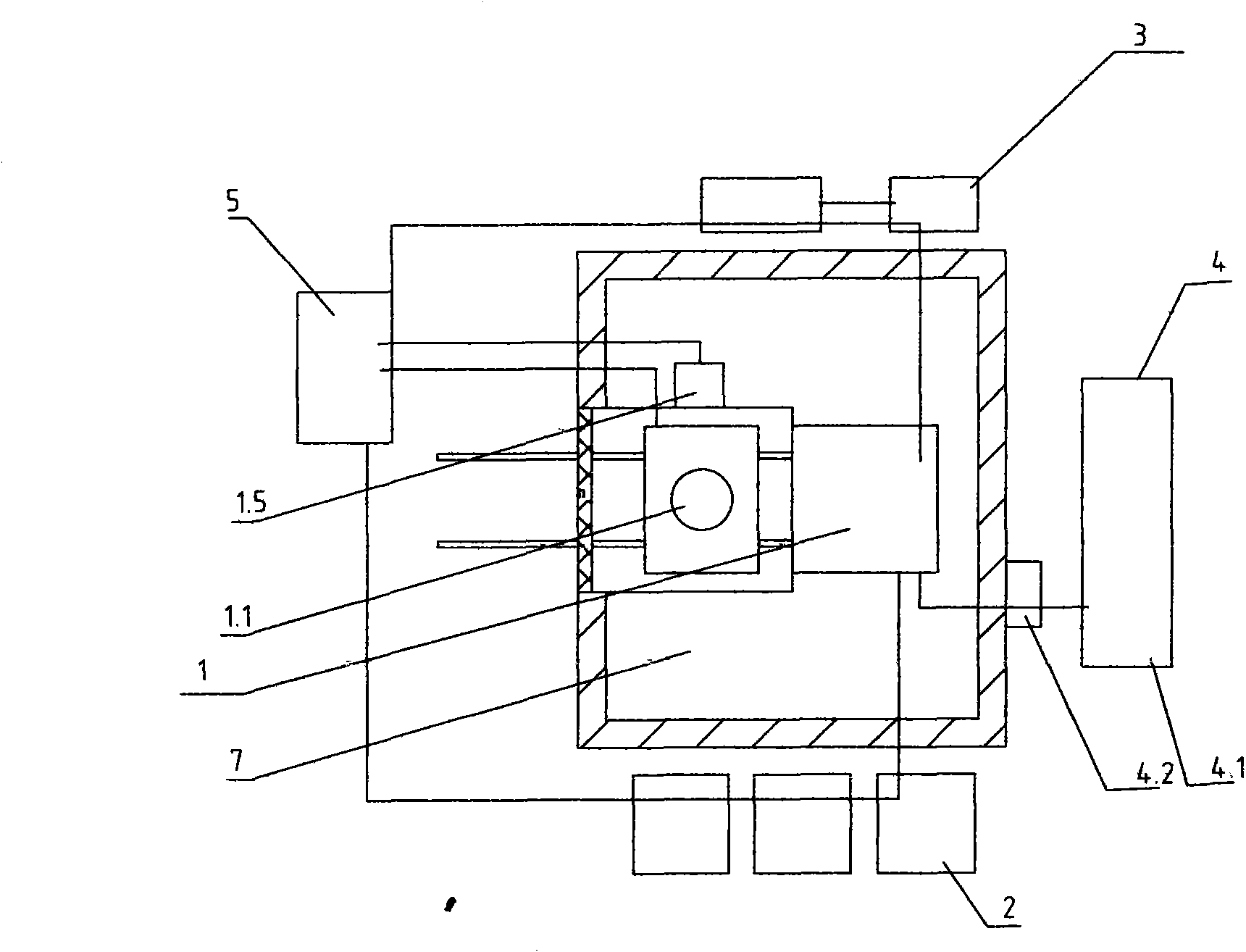

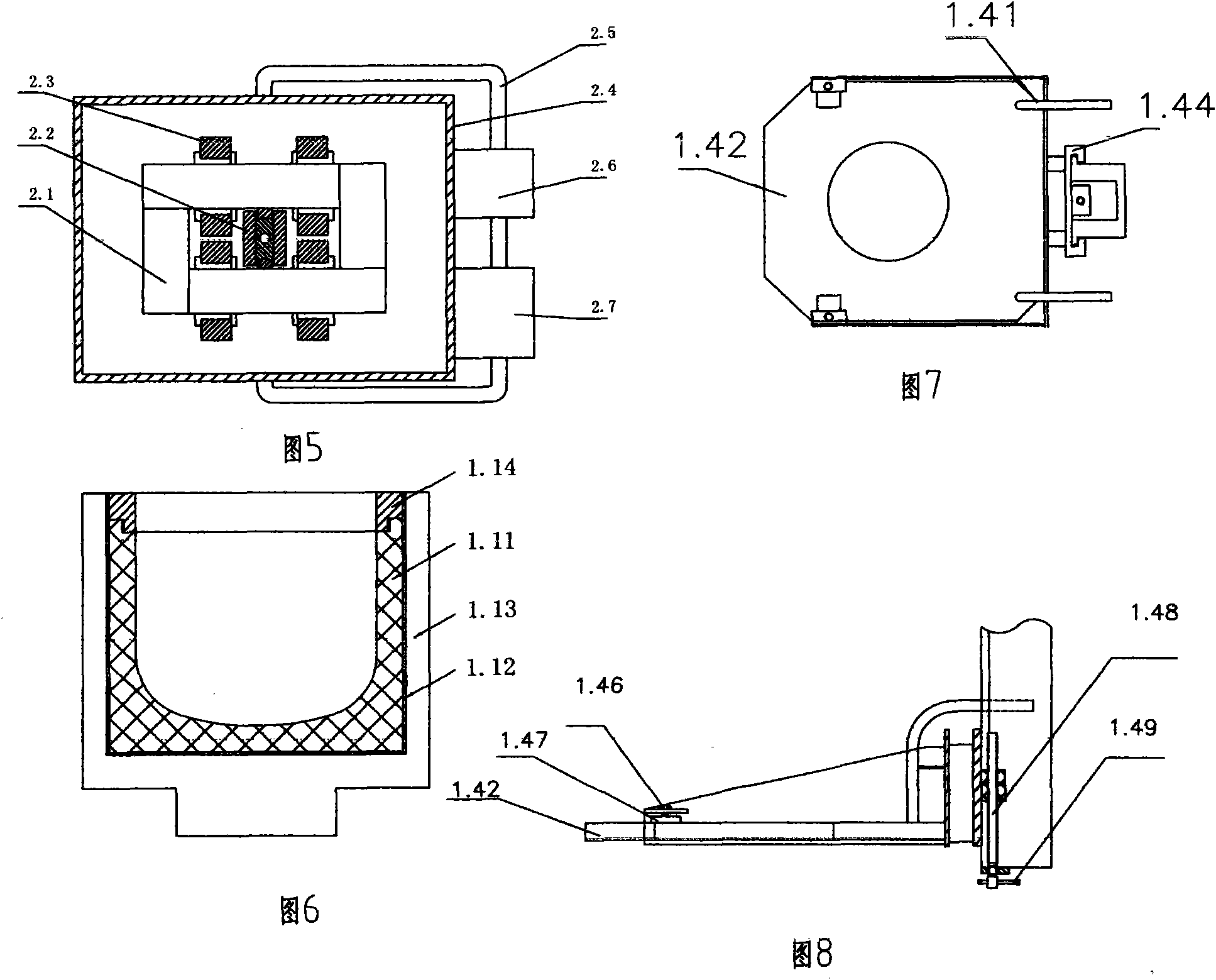

[0053] A 26-inch thick-walled quartz crucible:

[0054] Crucible size: outer diameter: 655mm, height: 600mm, thickness: 22mm, raw material: high-purity quartz sand (sio2 content 99.9999%), raw material weight: 260kg.

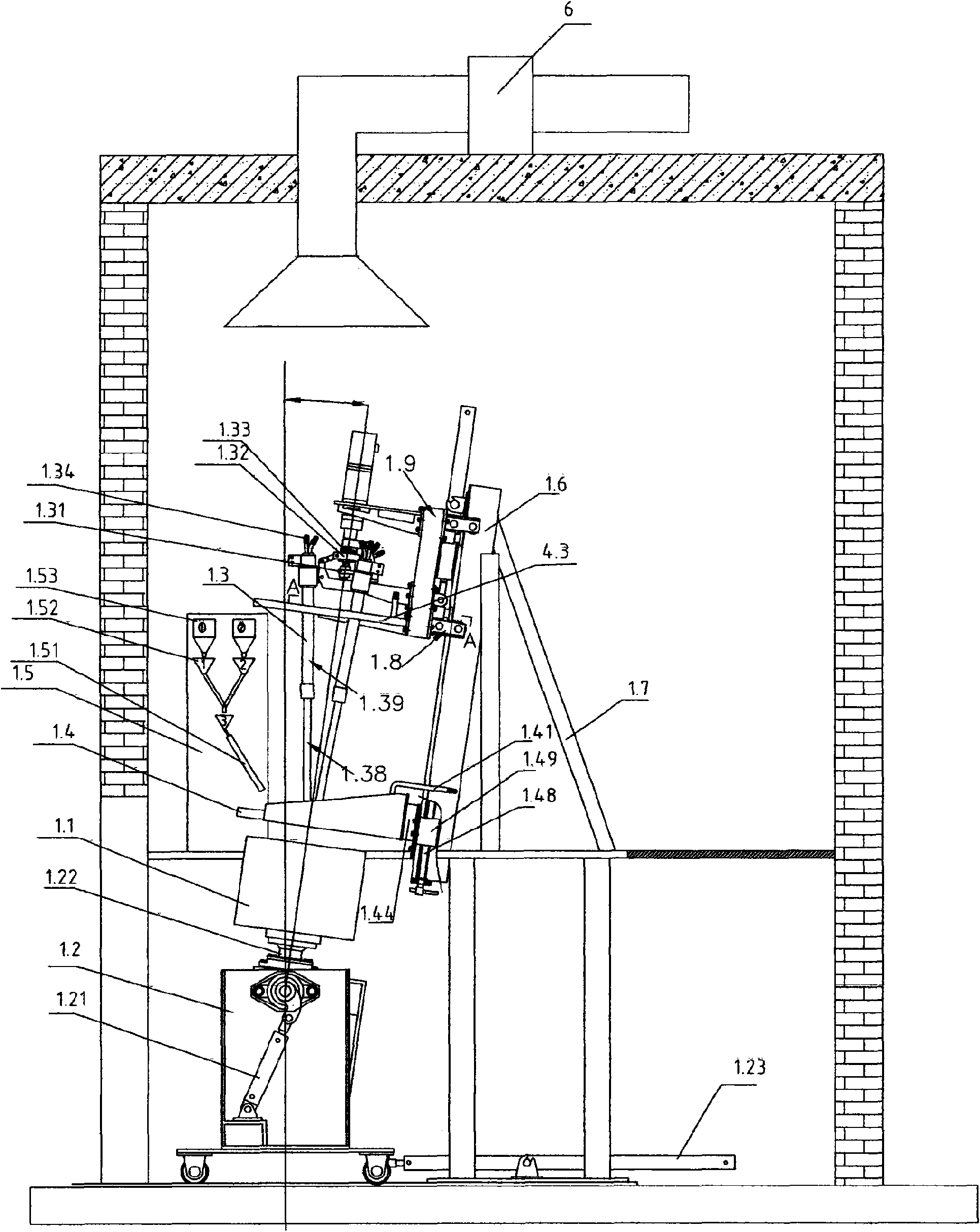

[0055] Manufactured by:

[0056] 1). Pour the quartz sand into the mold, shape it with a forming rod by centrifugal force, and then pull the mold into the melting chamber;

[0057] 2). The graphite electrode is energized and arced, and melted at a high temperature of 3500 ° C for 60 minutes;

[0058] 3). Cool naturally for 5 minutes, take it out and polish it.

Embodiment 2

[0060] A 26-inch thick-walled quartz crucible:

[0061] Crucible size: outer diameter: 665mm, height: 900mm, thickness: 50mm, raw material: high-purity quartz sand (sio2 content 99.9999%), raw material weight: 300kg;

[0062] Manufactured by:

[0063] 1). Pour the quartz sand into the mold, shape it with a forming rod by centrifugal force, and then pull the mold into the melting chamber;

[0064] 2). The graphite electrode is energized and arced, and melted at a high temperature of 3300 ° C for 90 minutes;

[0065] 3). Let it cool naturally for 10 minutes, take it out and polish it for shaping.

Embodiment 3

[0067] A 26-inch thick-walled quartz crucible:

[0068] Crucible size: outer diameter: 660mm, height: 800mm, thickness: 40mm, raw material: high-purity quartz sand (sio2 content 99.9999%), raw material weight: 280kg;

[0069] Manufactured by:

[0070] 1). Pour the quartz sand into the mold, shape it with a forming rod by centrifugal force, and then pull the mold into the melting chamber;

[0071] 2). The graphite electrode is energized and arced, and melted at a high temperature of 3400 ° C for 75 minutes;

[0072] 3). Cool naturally for 15 minutes, take it out and polish it for shaping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com