Coating apparatus capable of controlling mixing ratio and method thereof

A mixing ratio and coating technology, which is applied in the direction of control, coating, and surface coating of liquid using interconnected flow control elements, etc., can solve the problem that the coating agent cannot be used, the pressure and flow rate cannot be controlled, Can not clean paint replacement and other problems, to achieve the effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described with reference to the accompanying drawings which form a part hereof.

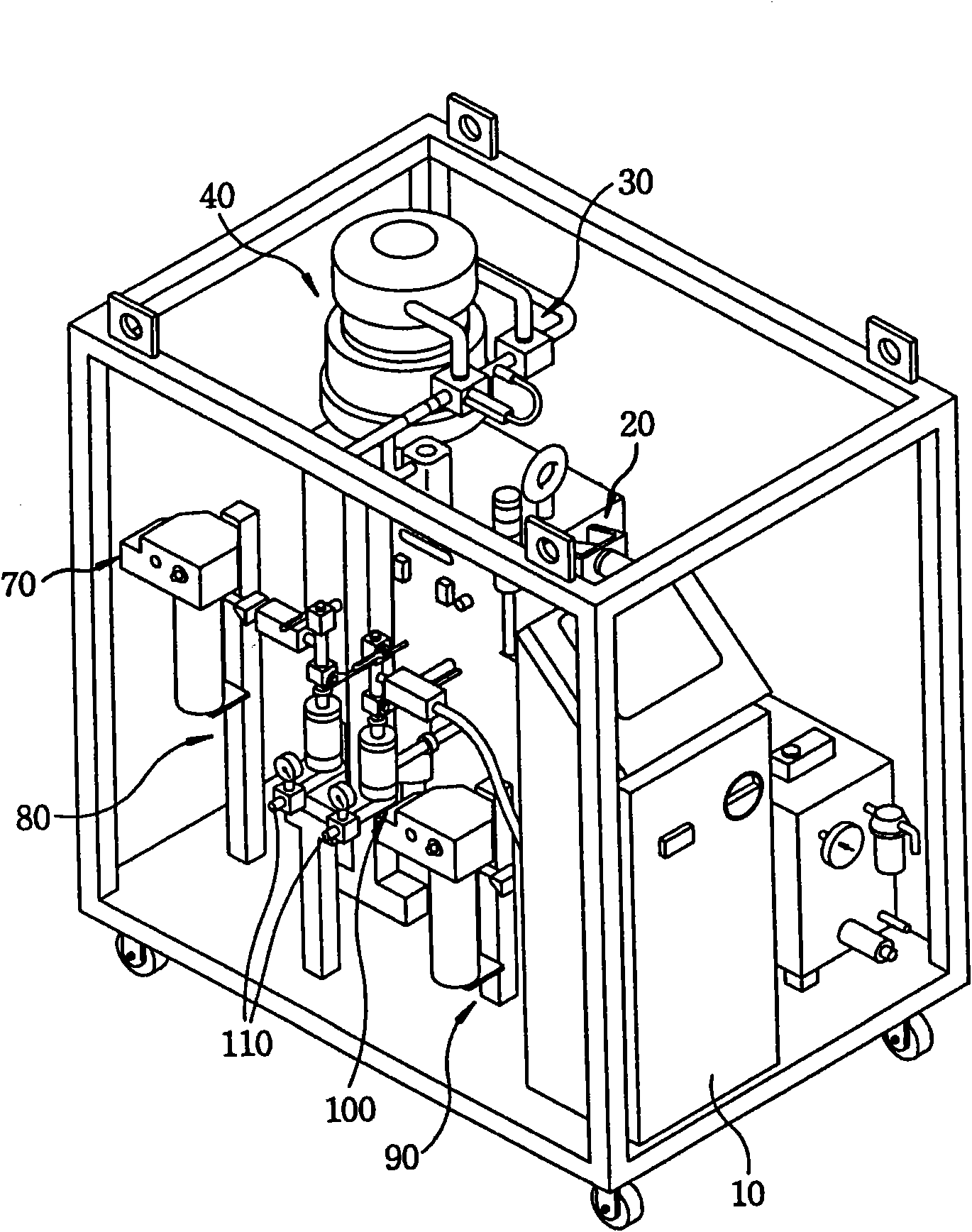

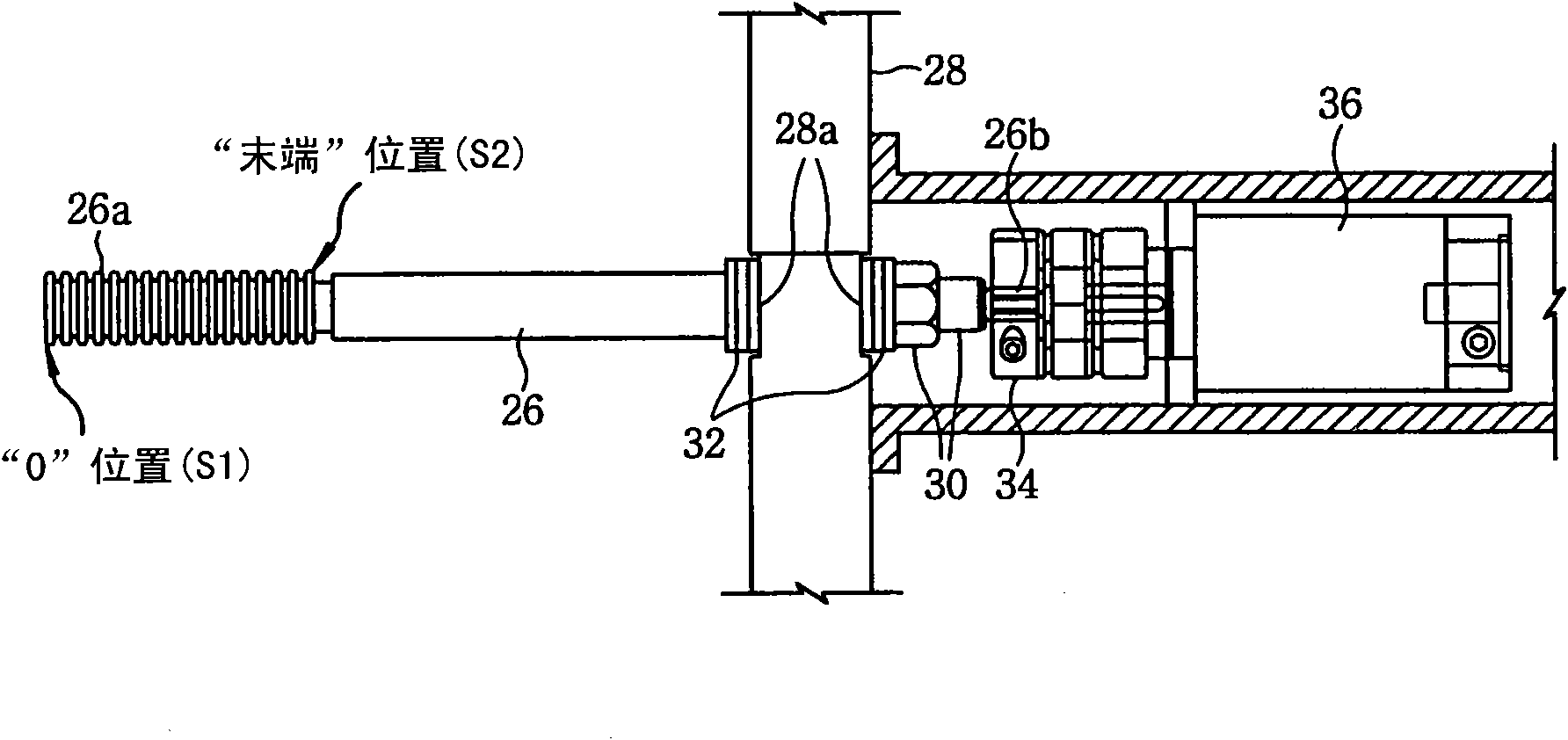

[0021] refer to figure 2 to 6, figure 2 It is a flowchart of a coating device capable of controlling the mixing ratio of a main coating agent and a hardening agent according to an embodiment of the present invention. The coating equipment includes a control unit 10, a spindle motor unit 20, a pressure regulator 30, a main pump 40, a main coating agent inlet 50, a hardening agent inlet 60, a main coating agent heating unit 70, and a main coating agent sensing unit. 80 , hardener heating unit 90 , hardener sensing unit 100 , mixer 110 , high-pressure spray gun 120 and swing device 130 . here, figure 1 show from figure 2 A 3D view of the coating equipment developed from the conceptual flow chart. image 3 provided figure 2 A perspective view of the spindle motor unit 20. exist image 3 In this case, the motor 36 is engaged with the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com