Yeast extract with seafood flavor and production method thereof

A technology of yeast extract and production method, applied in food science, food preparation, application and other directions, can solve the problems of undisclosed yeast extract and inconspicuous characteristic flavor, so as to enhance aroma and taste, improve characteristic aroma and taste. The effect of applying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The production of seafood-flavored yeast extract in this embodiment includes the following raw materials:

[0051] Abalone 50kg;

[0052] River crab 150kg;

[0053] 20kg of water;

[0054] Papain 1kg;

[0055] Yeast extract 360kg;

[0056] Accessories: hydrolyzed vegetable protein liquid 400kg, monosodium glutamate 8kg, salt 10kg, glucose 10kg, VB 1 2kg, 10.2kg of alanine, and 0.8kg of I+G (a mixture of disodium 5'-inosinate and disodium 5'-guanylate in a weight ratio of 1:1).

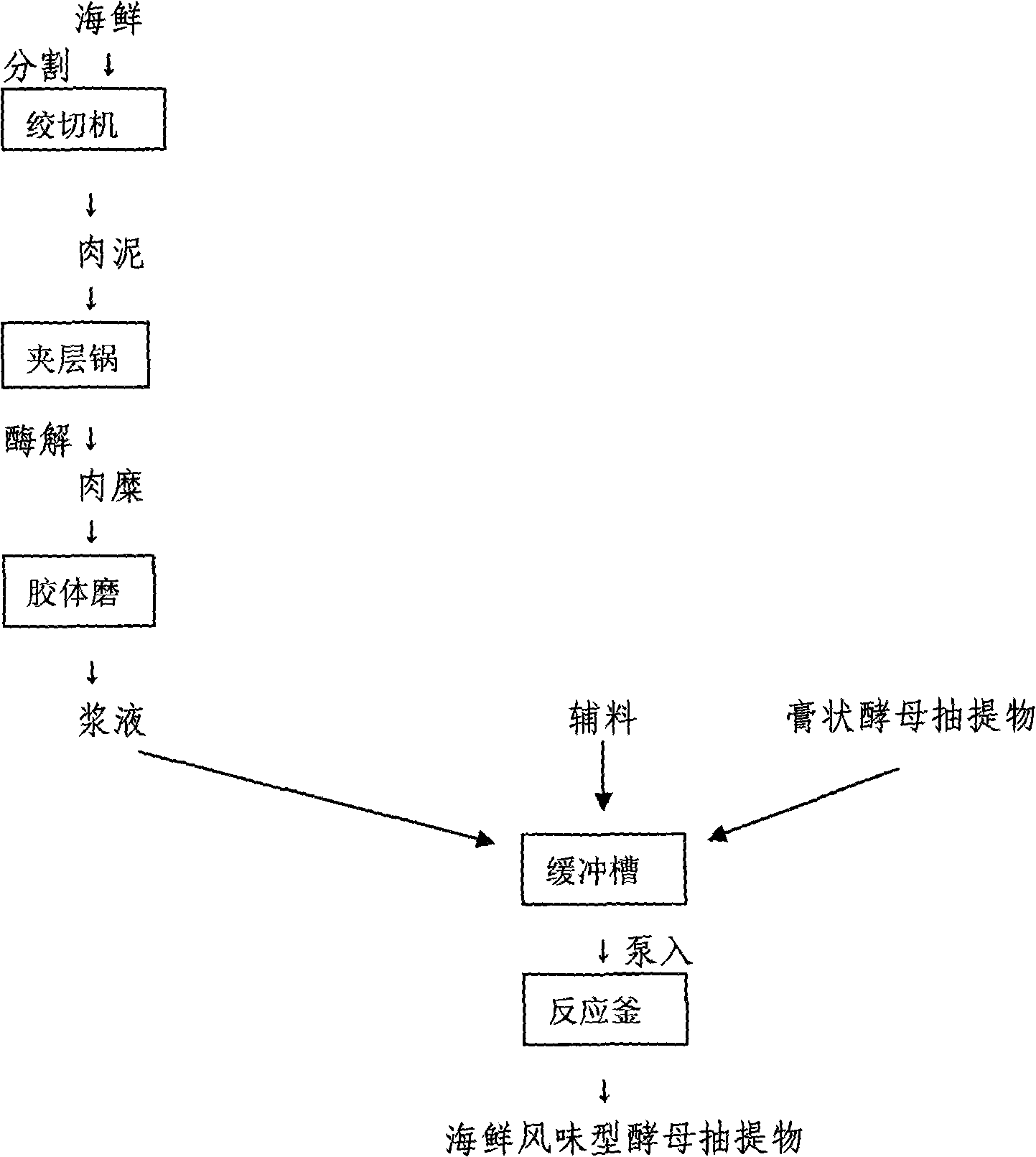

[0057] According to the above-mentioned components by weight, the seafood flavor type yeast extract is prepared, and the specific preparation method (see figure 1 )for:

[0058] (1) Seafood crushing: crush abalone and river crab, put them into a cutter, and grind them into meat paste;

[0059] (2) Enzyme inactivation of seafood: Put the minced meat into the sandwich pot, add water, heat up to 85°C, keep the temperature, make the color of the minced meat completely change from red to light...

Embodiment 2

[0065] The production of seafood-flavored yeast extract in this embodiment includes the following raw materials:

[0066] Abalone 50kg;

[0067] River crab 150kg;

[0068] 10kg of water;

[0069]Papain 1kg;

[0070] Yeast extract 410kg;

[0071] Accessories: hydrolyzed vegetable protein 350kg, monosodium glutamate 8kg, salt 10kg, glucose 10kg, VB 1 2kg, alanine 10kg, I+G (the mixture of disodium 5'-inosinate and disodium 5'-guanylate in a weight ratio of 1:1) 1kg.

[0072] According to the above-mentioned components by weight, the seafood flavor type yeast extract is prepared, and the specific preparation method (see figure 1 )for:

[0073] (1) Broken seafood: Abalone and river crab need to be crushed to form meat paste;

[0074] (2) Enzyme inactivation of seafood: Put the minced meat into the sandwich pot, add water, heat up to 95°C, keep the temperature, make the color of the minced meat completely change from red to light, then stop, and lower the temperature to belo...

Embodiment 3

[0080] The production of seafood-flavored yeast extract in this embodiment includes the following raw materials:

[0081] Abalone (50kg), river crab (150kg);

[0082] 20kg of water;

[0083] Protease 1kg;

[0084] Yeast extract 380kg;

[0085] Accessories: hydrolyzed vegetable protein 380kg, monosodium glutamate 8kg, salt 10kg, glucose 10kg, VB 1 2kg, alanine 12kg, I+G (the weight ratio of 5'-inosinate disodium and 5'-guanylate disodium is 1:1 mixture) 1kg.

[0086] According to the above-mentioned components by weight, the seafood flavor type yeast extract is prepared, and the specific preparation method (see figure 1 )for:

[0087] (1) Broken seafood: Abalone and river crab need to be crushed to form meat paste;

[0088] (2) Enzyme inactivation of seafood: Put the minced meat into a jacketed pot, add water to heat up to 90°C, keep the temperature, stop the color of the minced meat from red to light, and lower the temperature to below 60°C. (3) Enzymolysis of seafood: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com