Defect detection system of panel component

A technology for defect detection and components, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as light intensity attenuation, energy consumption, production costs, light box thickness and bulky volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

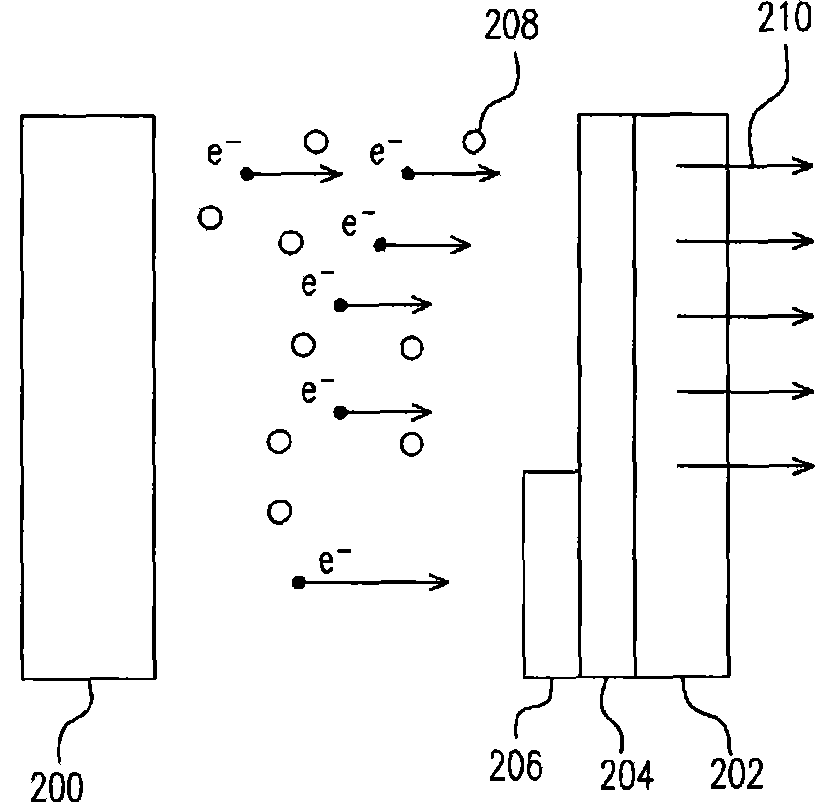

[0034] For example, the present invention can be applied to the product inspection planar light source equipment required on the production line. For the light source part of the detection light box, the present invention proposes an electron emission type flat light source (Flat electron emission lamp, FEEL) as the detection light source. Here, the planar light source refers to a planar light source, which can be a curved surface or a planar surface as required.

[0035] The light source of the detection light box is changed to an electron-emitting planar light source. Because it is a planar light source, there is no need to use a diffuser, which can reduce light loss. In addition, the light source device of the present invention can be manufactured into light sources of different sizes and shapes as required, for example, rectangular or circular as shown in FIG. 8 . The reflective mechanism only needs a flat reflective surface, and the overall detection equipment can be thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com