Rotor rub-impact acoustic emission recognition method based on modal waves and gauss hybrid models

A technology of Gaussian mixture model and recognition method, which is applied in the direction of vibration measurement in solids, measuring vibration, measuring devices, etc., can solve the problems of difficult recognition, noise interference, and insufficient depth, and achieve the goal of improving recognition rate, good training and recognition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

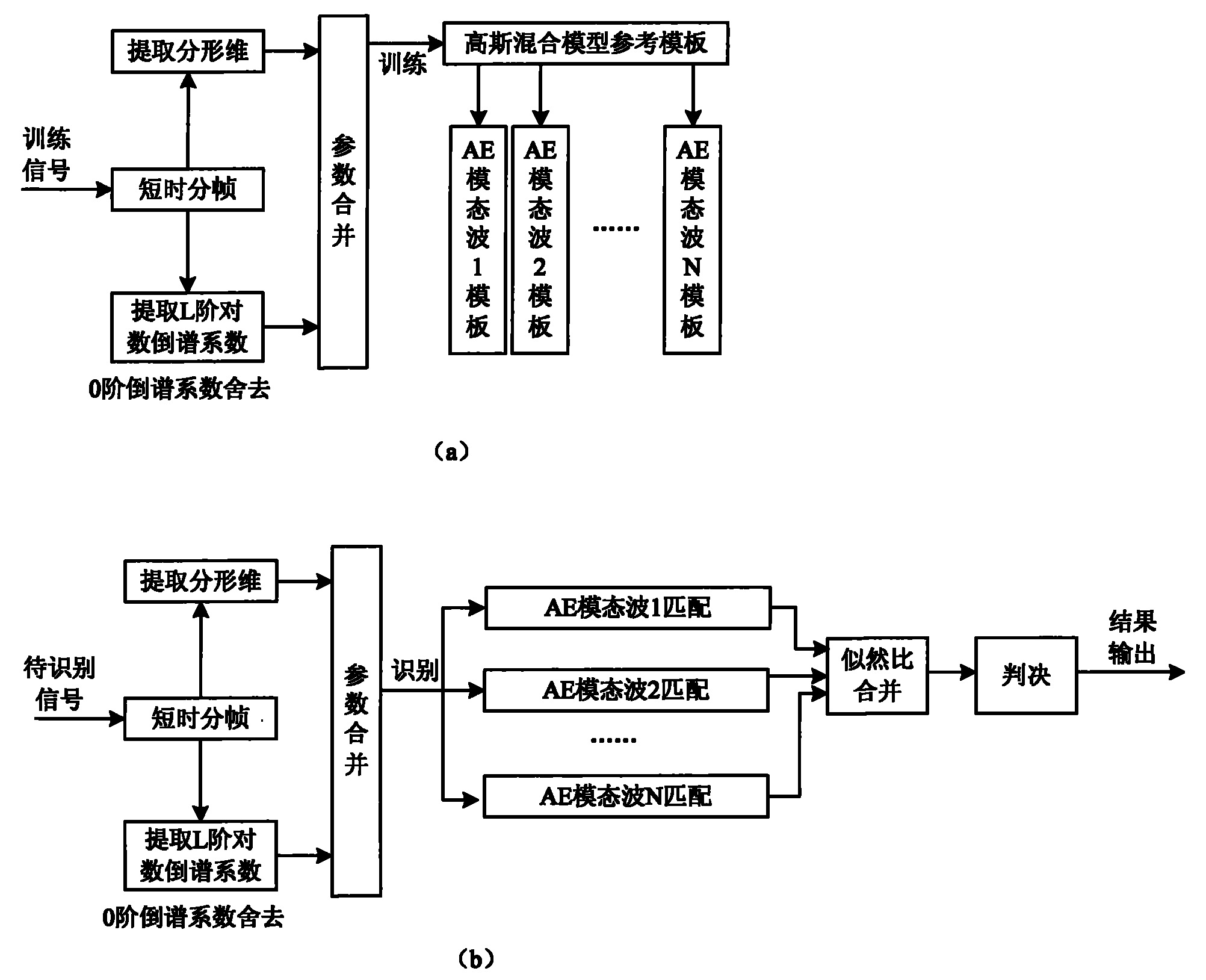

[0025] figure 1 It is an overall flow chart of the AE signal recognition method. The following will follow figure 1 The flow shown in the figure details the specific implementation process and manner of each block diagram.

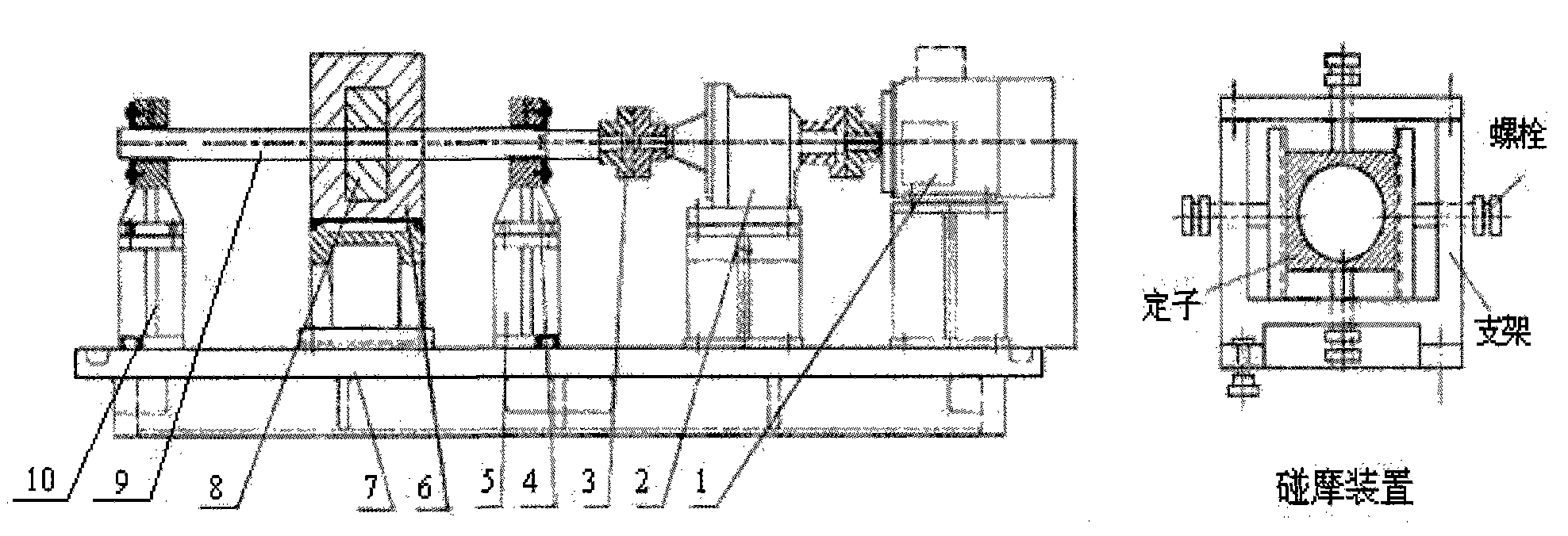

[0026] 1. Obtaining and framing of rubbing signals

[0027] Rotor rubbing test bench such as figure 2 shown. The static and dynamic rubbing is simulated by a movable rubbing bracket installed on the base of the rotor table. The rubbing bracket is installed between the bearing housings 1 and 2, and telescopic bolts are installed on the bracket, facing the center of the rotating shaft radially along the rotating shaft, and rubbing is generated by adjusting the bolts. The test system uses the SR150 sensor with a frequency range of 20-300kHz; the bandwidth of the preamplifier is 20kHz-2000kHz, and the gain is 40dB; the gain of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com