Sliding cylinder external-open gas distribution engine

An engine and sliding cylinder technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of airflow fluidity, airflow flow area and gas distribution opening time limit, etc., to achieve simple structure, improved efficiency, and airflow flow The effect of improving the degree of mixing with gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

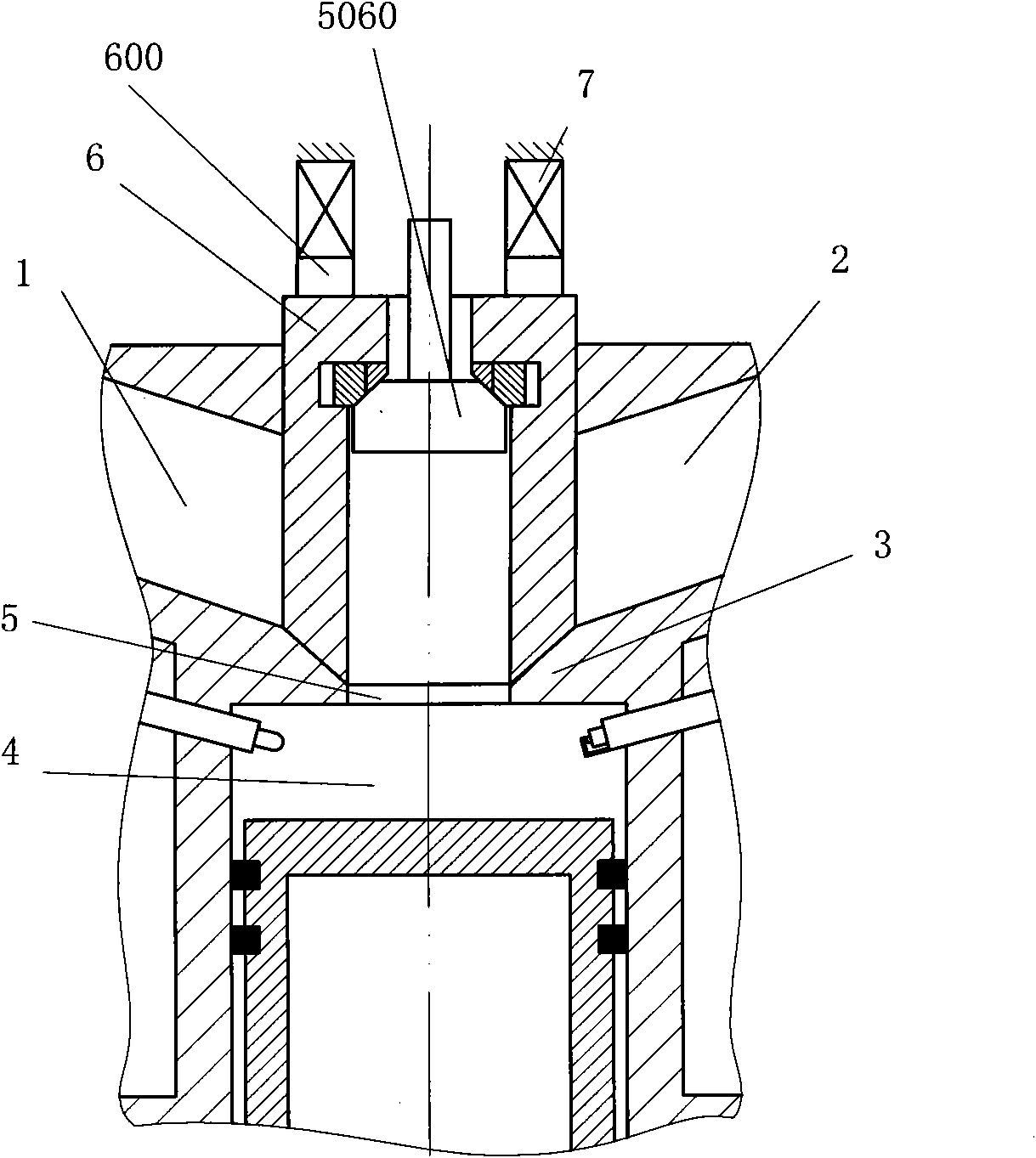

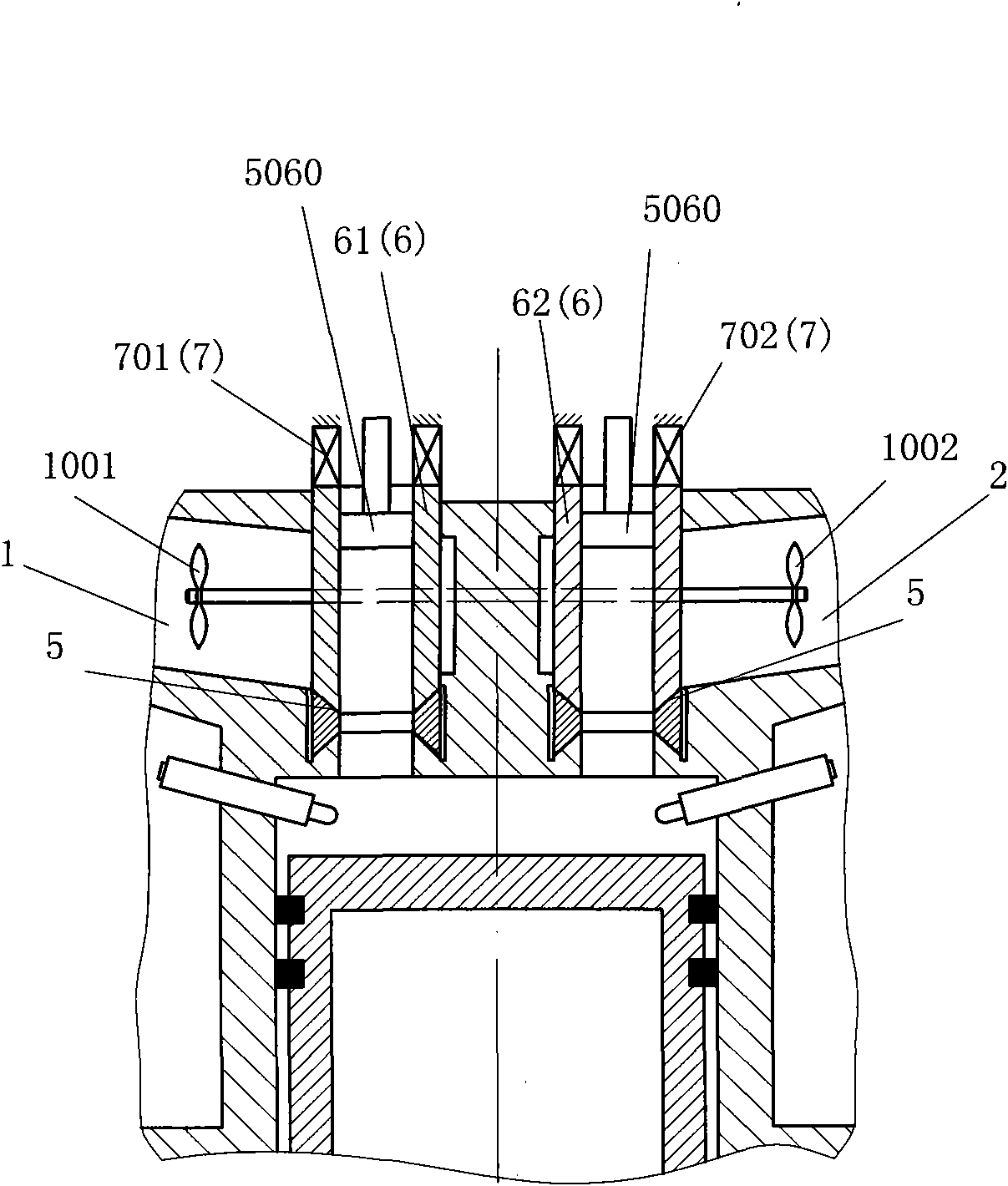

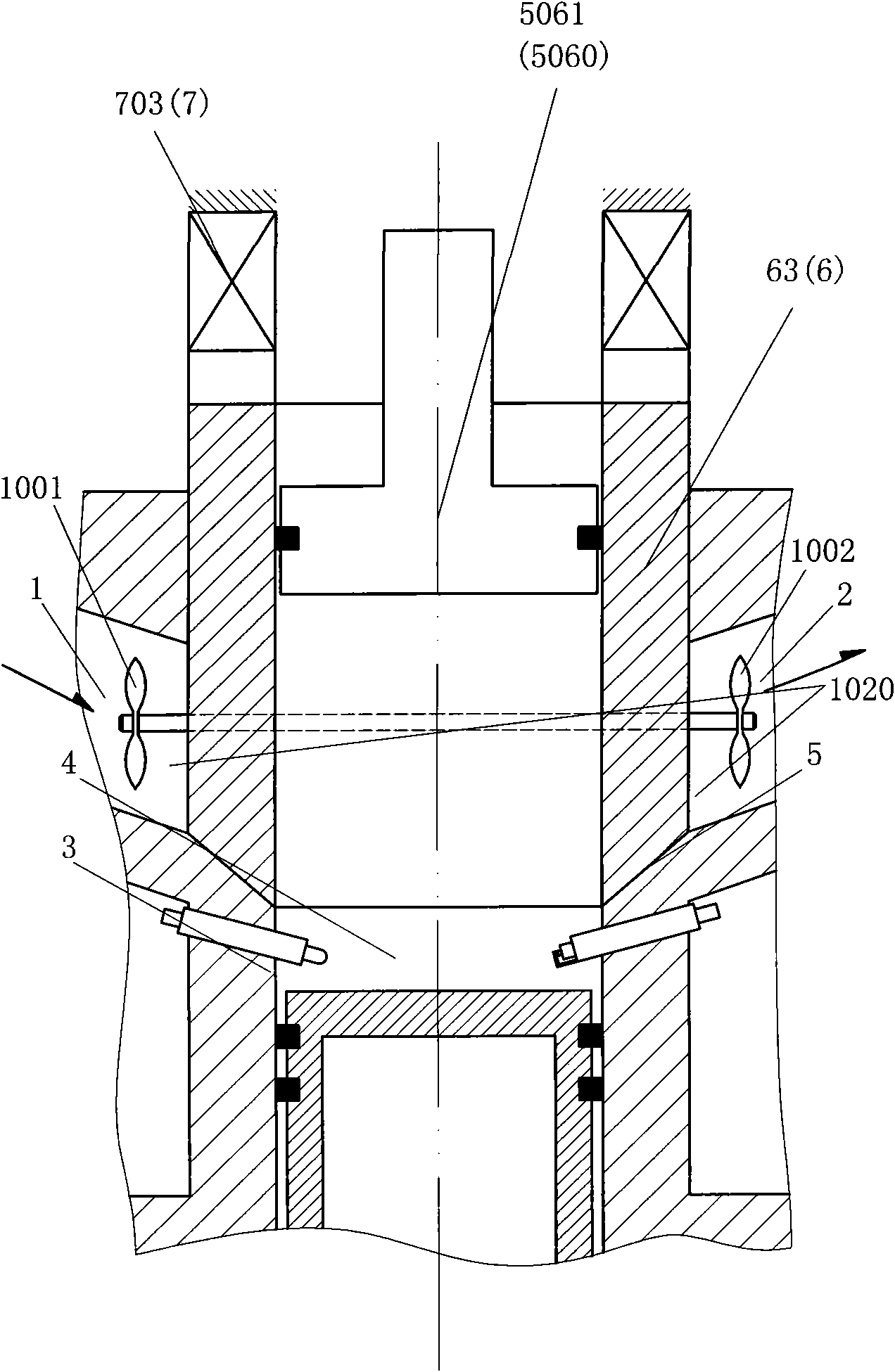

[0049] Such as figure 1 The shown sliding cylinder outwardly opening gas distribution engine includes an intake port 1, an exhaust port 2, an outer wall of the combustion chamber 3 and a combustion chamber 4, and one or more outer air distribution seats are arranged on the outer wall of the combustion chamber 3. (5), the outwardly opening gas distribution seat opening 5 communicates with the combustion chamber 4 respectively or simultaneously with the air intake passage 1 and the exhaust passage 2, and each of the outwardly opening air distribution seat openings 5 Correspondingly set an outward matching cylinder liner 6, a sealing body 5060 is arranged inside the outward opening matching cylinder liner 6, and the outward opening matching cylinder liner 6 is controlled by the timing control device 7 of the matching cylinder liner directly or through the connecting piece 600 The engine timing requires opening and closing the corresponding outward opening valve seat port 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com