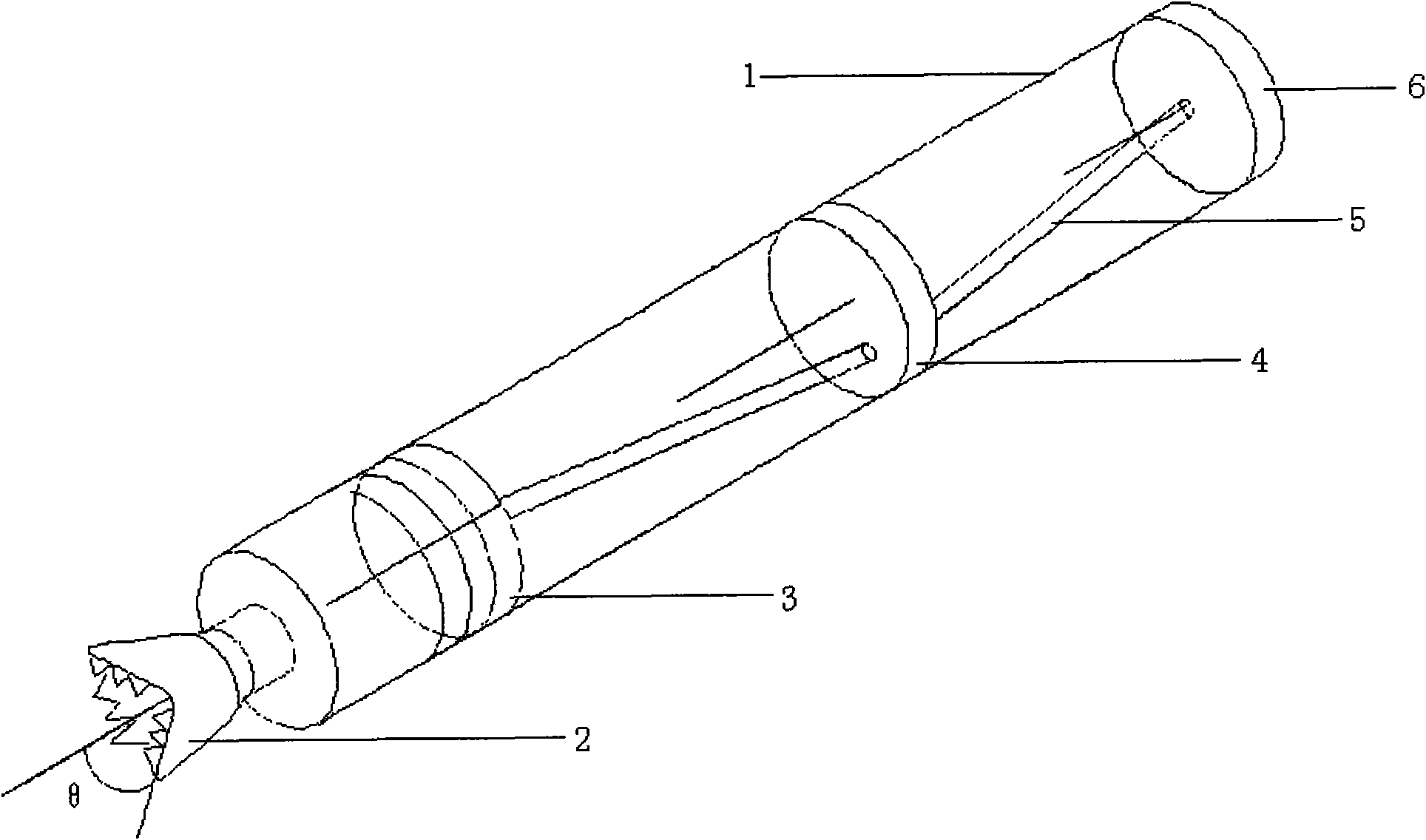

Structure design method for guiding type rotary steering drilling tool

A technology of rotary steerable drilling and structural design, which is applied to drilling equipment and methods, drilling equipment, directional drilling, etc., and can solve problems that have not been studied in depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

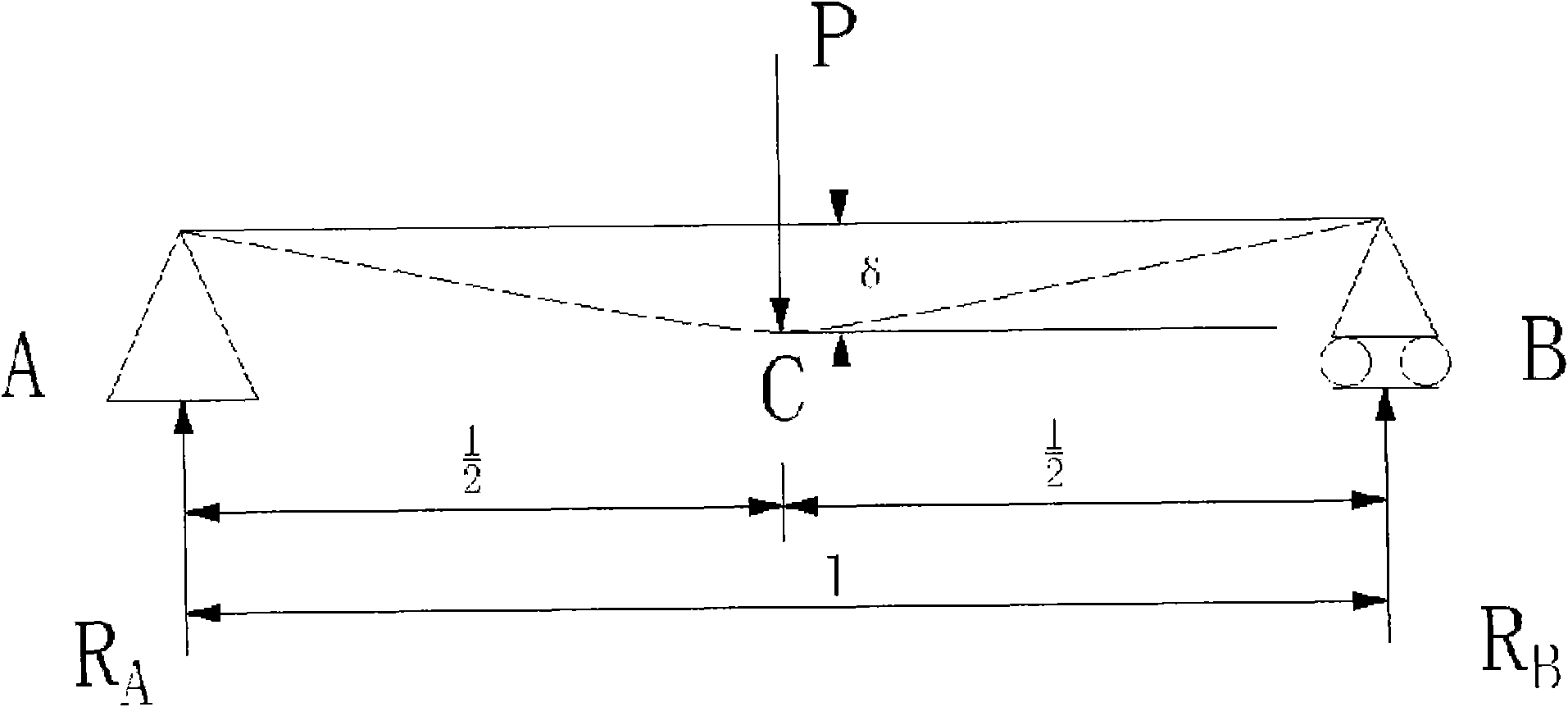

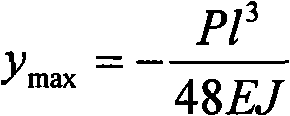

[0103] Example 1: The R of the mandrel 5 in the pointing rotary steerable drilling tool 外径 and R 内径 are 9.5cm and 4.5cm respectively, and the length l of the mandrel 5 is 400cm, the bias mechanism 4 is located at the midpoint of the mandrel 5, that is, AC=200cm, and the maximum deflection y of the mandrel 5 is set max = 2cm, the variation law of the axial displacement λ of the mandrel 5 after bending and the stress σ produced by the mandrel 5 is as follows, as shown in Table 1:

[0104] Table 1

[0105] Preface

No

R 外径

R 内径

J

E

y

l

P

σ

1

9.5

4.5

379.5

2100000

1

400

597.7

0.017

90.563

2

9.5

4.5

379.5

2100000

2

400

1195.4

0.069

362.250

3

9.5

4.5

379.5

2100000

3

400

179...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com