Process for preparing atazanavir bisulfate and novel forms

A technology of atazanavir and bisulfate, applied in the field of preparing HIV protease inhibitor atazanavir bisulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

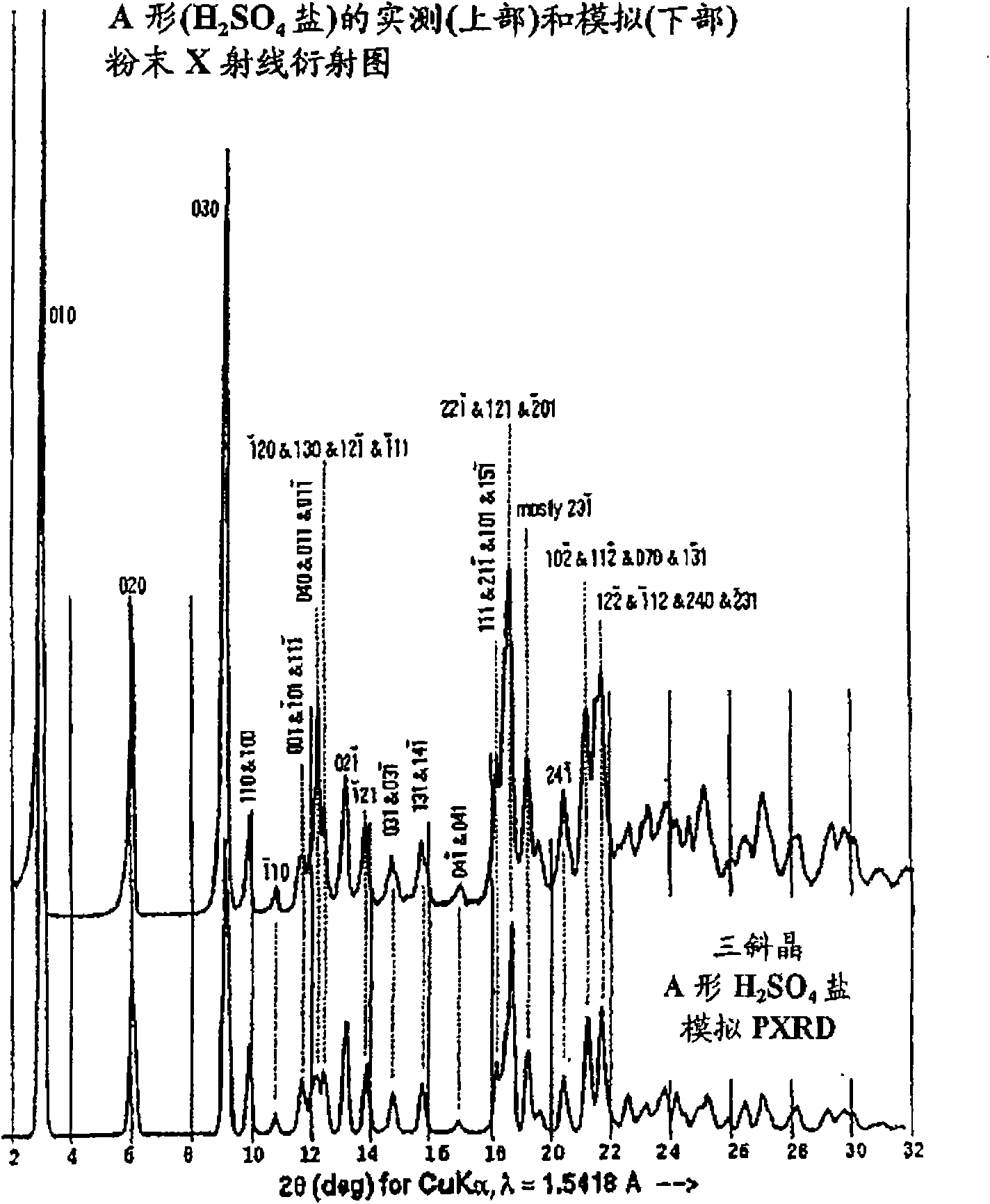

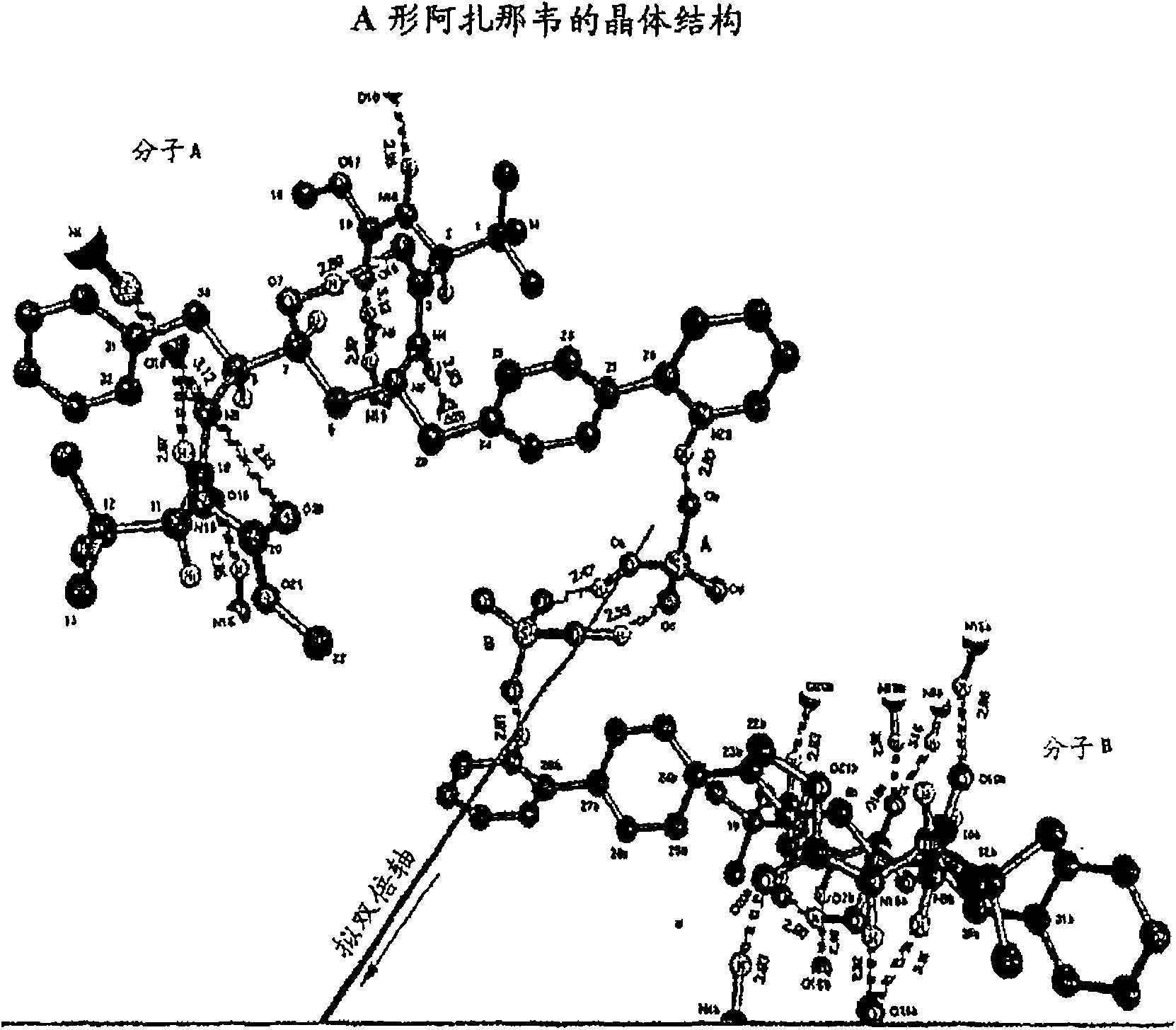

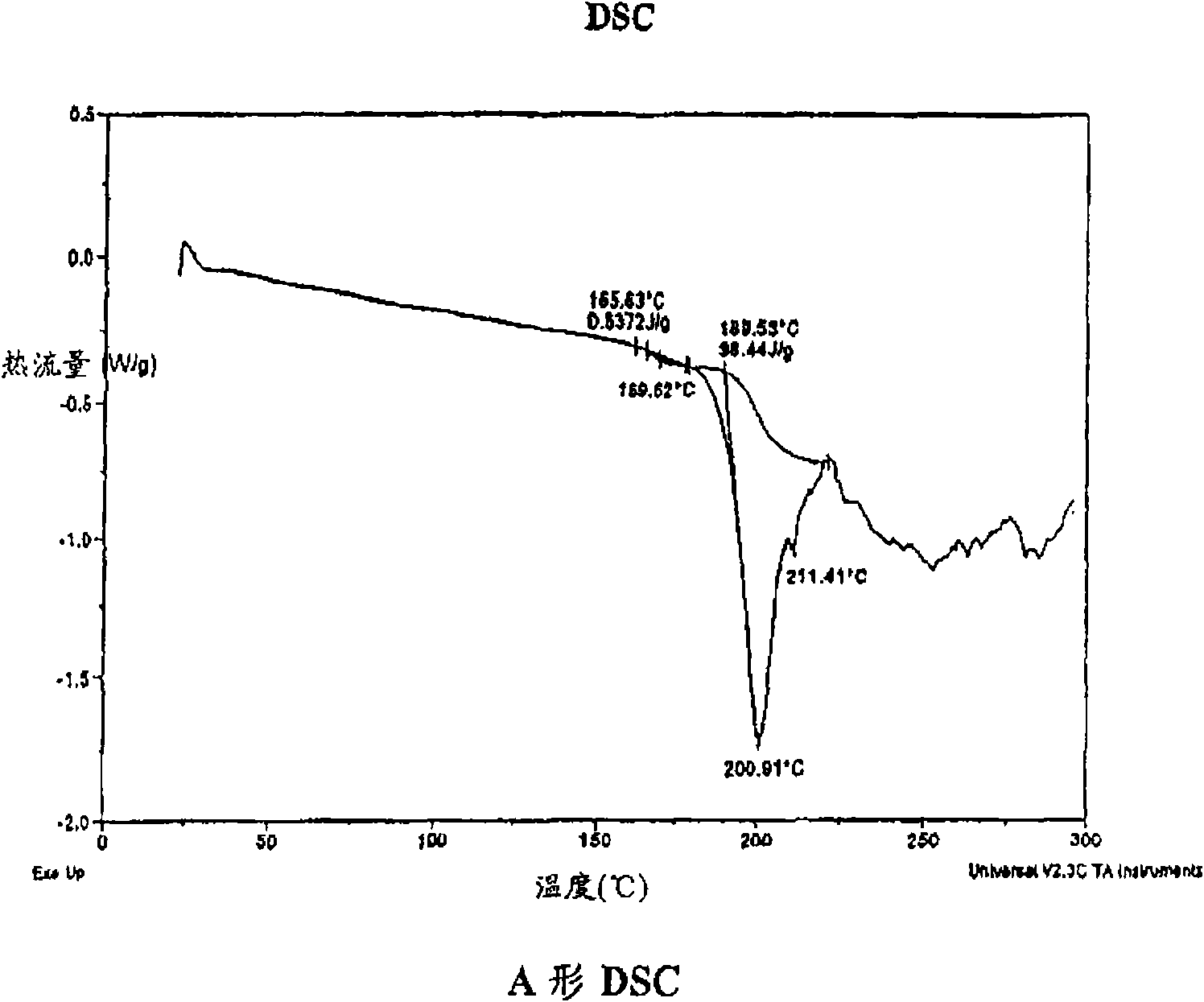

[0176] 1-[4-(pyridin-2-yl)phenyl]-5(S)-2,5-bis{[N-(methoxycarbonyl)-L-tert-leucyl]amino}-4-( S)-Hydroxy-6-phenyl-2-azahexane, bisulfate (Form A) (Atazanavir bisulfate-Form A)

[0177]

[0178] (1-[4-(pyridin-2-yl)phenyl]-5(S)-2,5-bis[tert-butoxycarbonyl)amino]-4(S)-hydroxy-6-phenyl-2 -Azahexane.3HCl (triamine.3HCl salt))

[0179] The protected triamine 1-[4-(pyridin-2-yl)phenyl]-5(S)-2,5-bis[tert-butoxycarbonyl)amino]-4(S)-hydroxyl-6 -Phenyl-2-azahexane

[0180]

[0181] (100g, 0.178mol) and CH 2 Cl 2 (500 mL; 5 mL / g protected triamine feed) (its preparation is described in Z. Xu et al., Process Research and Development for an Efficient Synthesis of the HIV Protease Inhibitor BMS-232, 632, Organic Process Research and Development, 6 , 323-328 (2002)) into a 1000 mL 3-necked round bottom flask equipped with a mechanical stirrer, nitrogen inlet, and temperature sensor, and the resulting slurry was stirred while maintaining the temperature at about 5 to about 22°C.

...

Embodiment 2

[0230] Atazanavir bisulfate-C pattern substance

[0231] Method A:

[0232] Atazanavir bisulfate Form A crystals (prepared as described in Example 1) (25.33 g) were suspended in 200 mL of water, and the mixture was mechanically stirred to give a viscous gel, which was dried.

[0233] The dry mixture was triturated with a spatula to obtain the Pattern C material. The powder X-ray diffraction pattern of the C-mode material is as follows Figure 6 show.

[0234] Method B:

[0235] Wet granulate the atazanavir bisulfate Form A crystals with sufficient water (approximately 40% w / w) in a suitable mixer-granulator. Dry the wet mass in an oven. The product is sieved to size using a suitable sieve. The X-ray diffraction pattern of the obtained product and Figure 6 Concordance with the C-mode species shown.

[0236] The characteristics of the differential scanning calorimetry thermogram of C mode are as follows: Figure 7 It is shown that there is generally an endotherm in the...

Embodiment 3

[0239] Atazanavir Bisulfate-Form E3 (Triethanol Solvate)

[0240] In a 100mL 3-necked round-bottomed flask equipped with a mechanical stirrer, a temperature sensor and a pressure-balanced addition funnel, atazanavir free base (prepared according to Part C in Example 1) (3.0g, 4.26mmol) was dried at 200 Slurry was made in proof ethanol (20.25 mL, 6.75 mL / g free base).

[0241] Concentrated H 2 SO 4 (0.25 mL, 0.46 g, 4.69 mmol, 1.1 eq.) was added to the atazanavir free base slurry maintained at 20-25 °C. The resulting solution (KF 0.2 to 1.0% water) was polish filtered (Whatman #1 paper), the filter was rinsed with 2.25 mL of absolute ethanol, and the rinse was added to the filtered solution. The solution was heated to 37°C, seeded with 10 mg of amorphous atazanavir bisulfate derived from Form E3 crystals (by exposing Form E3 crystals to ambient temperature), and the mixture was stirred for 15 minutes. Heptane (380 mL, 8.25 mL / g free base) was added over 1 hour. The resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com