Can opener for cutting ink barrel

A can opener, ink technology, applied in the direction of opening closed containers, applications, household appliances, etc., can solve problems such as uneven openings, ink dumping outside, waste of the environment, etc., to achieve convenient ink, convenient dumping, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

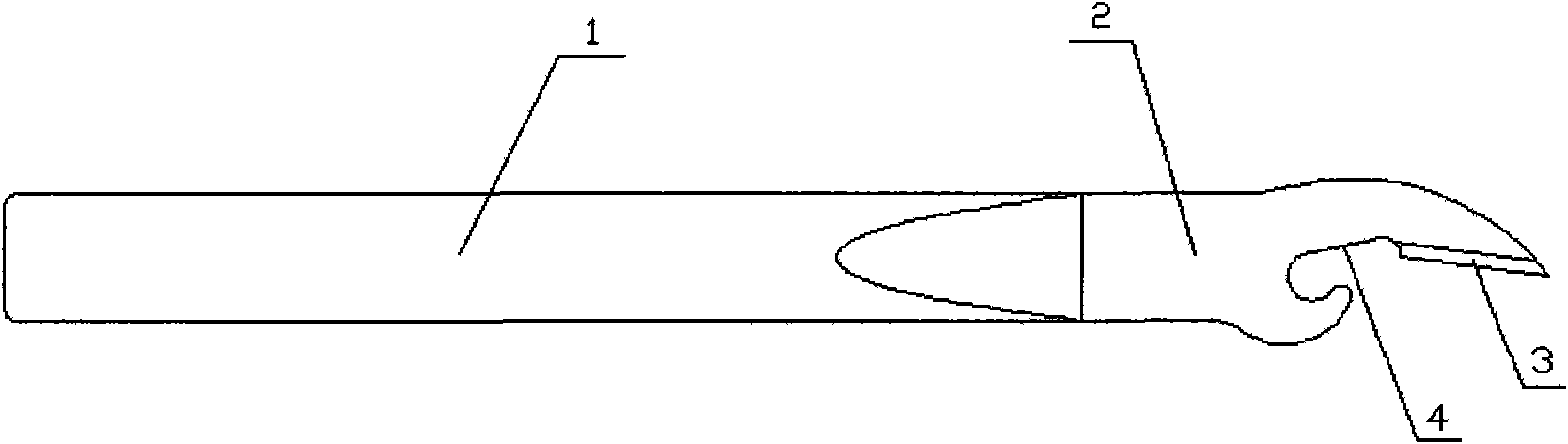

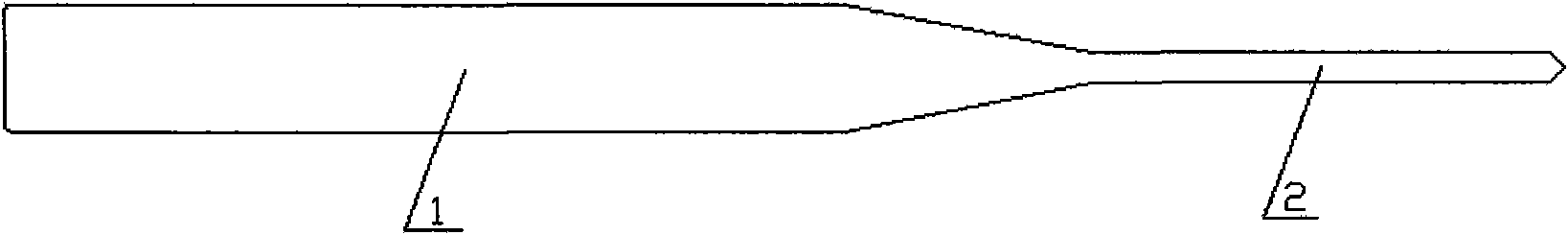

[0011] Such as figure 1 and figure 2 As shown, a can opener for cutting ink barrels provided by the present invention includes a knife handle 1, a knife head 2 is provided at the end of the knife handle 1, and an obliquely downward knife is provided at the front end of the knife head 2 The blade 3 has an angle of inclination of 8°, and the part of the cutter head 2 located behind the blade 3 is provided with a bayonet 4 adapted to the edge of the ink barrel mouth, because the flange of the ink barrel mouth is generally arc-shaped, Therefore, the bayonet port 4 is also arc-shaped when viewed from the side, so that the bayonet port 4 can be stuck on the edge of the mouth of the ink barrel.

[0012] During use, the user first holds the ink barrel to be opened with the hand, snaps the bayonet 4 into the edge of the barrel mouth of the ink barrel, and uses the bayonet as a fulcrum to lift the knife handle 1 upwards, because the head of the can opener is There is an obliquely dow...

Embodiment 2

[0014] The difference between this embodiment and Embodiment 1 lies in the shape of the bayonet 4. If the flange of the ink barrel mouth is in the shape of an angular arc, then the bayonet 4 also needs to be adapted to it, so that the bayonet 4 can be locked. On the edge of the mouth of the ink barrel, other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com