Method for determining retention rate of fluorescent whitening agent in pulp fiber system

A fluorescent whitening agent, pulp fiber technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of poor operability, complicated measurement steps, and difficult to master, and achieve easy mastery, simple measurement steps, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

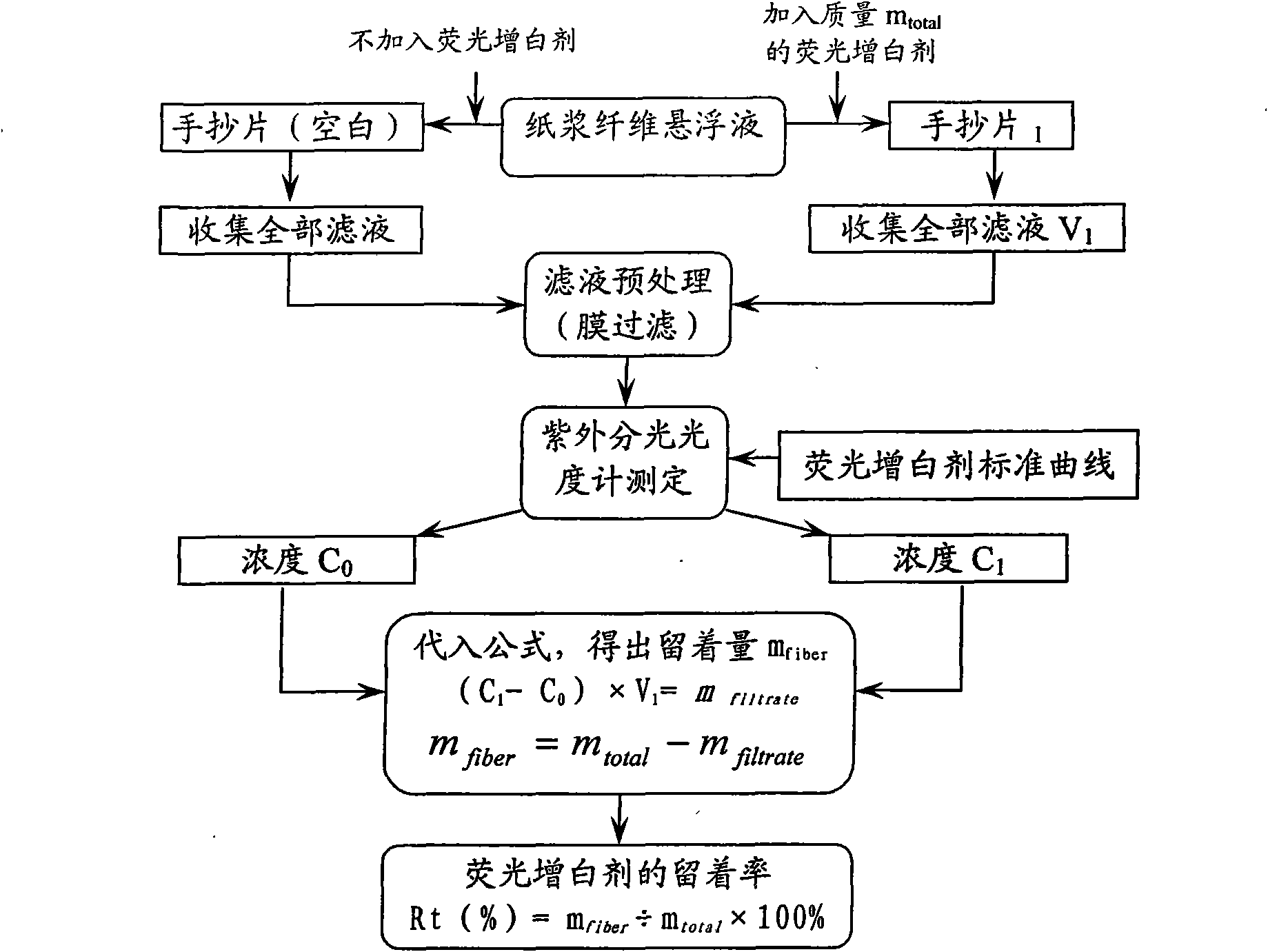

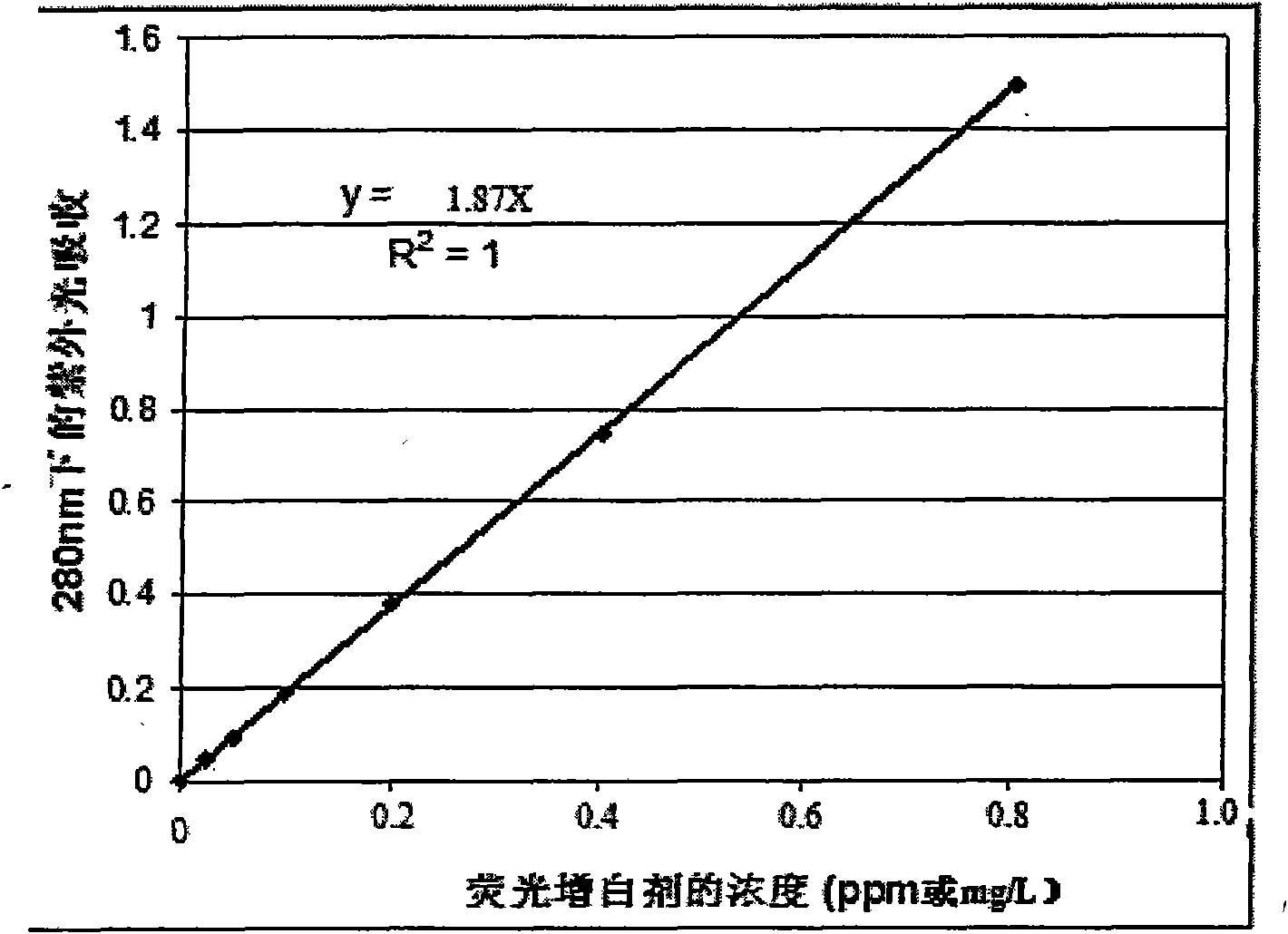

Method used

Image

Examples

Embodiment

[0040] 1) Experimental raw materials

[0041] pulp

[0042] Softwood (spruce) bleached kraft pulp (brightness 87.2% ISO, freeness 470ml CSF) and hardwood (eucalyptus) bleached kraft pulp (brightness 88.4% ISO, freeness 490ml CSF) were produced by Canada Tembec Inc. supply;

[0043] drug

[0044] Fluorescent whitening agent (Tinopal ABP-A) is provided by Swiss Ciba Chemical Company;

[0045] Filter material:

[0046] The 0.1μm filter membrane (made of nylon) is provided by MAGNA Company of the United States;

[0047] Laboratory equipment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com