Multifunctional horizontal well completion tubular pile device

A technology for well completion strings and horizontal wells, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of complicated well completion operations and high costs, achieve high seepage area, low cost, and prevent well Collapsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the embodiment of a kind of horizontal well completion pipe string device of the present invention is described further:

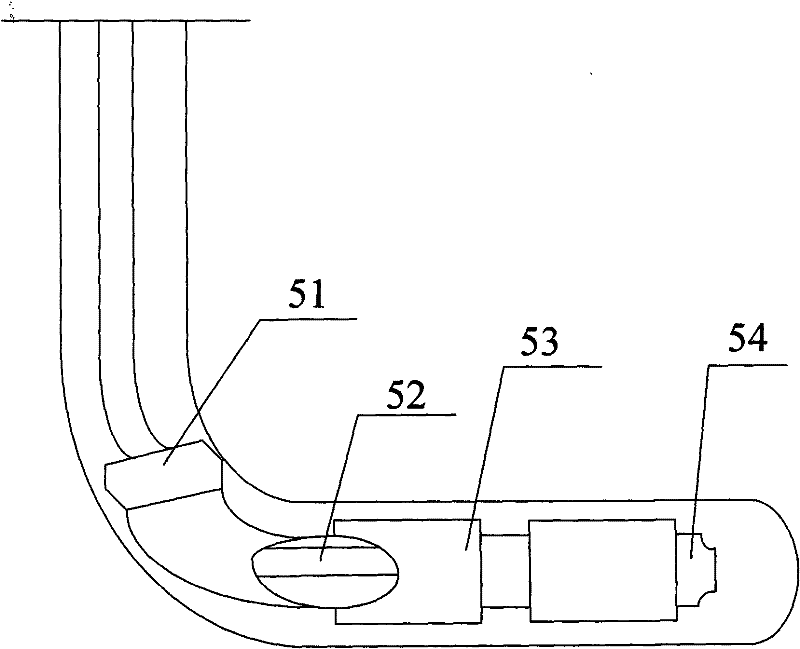

[0021] A horizontal well completion string device, comprising a screen 52, an inner flushing pipe 53 and a flushing tool 54, and also includes a hanging packer 51, one end of the screen is connected to the hanging packer, The other end is connected with the flushing tool, the inner flushing pipe is inserted into the sand control string composed of the packer and the screen pipe, and the lower end of the inner flushing pipe is sealed and inserted into the flushing tool.

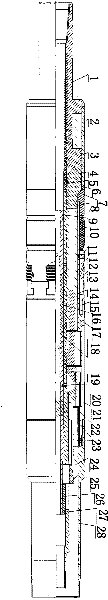

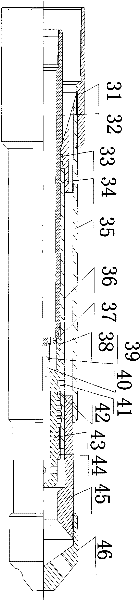

[0022] The suspended packer includes a packer inner central pipe 16, a setting assembly and a hand-discharging assembly, the setting assembly and the disengaging assembly are arranged on the outer surface of the inner central pipe, and the setting The sealing component is connected with the said throwing component.

[0023] The settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com