Spinning machine with individual spindle drive

A spinning machine and spindle technology, applied in the field of spinning machines or twisting machines, can solve problems such as high wiring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

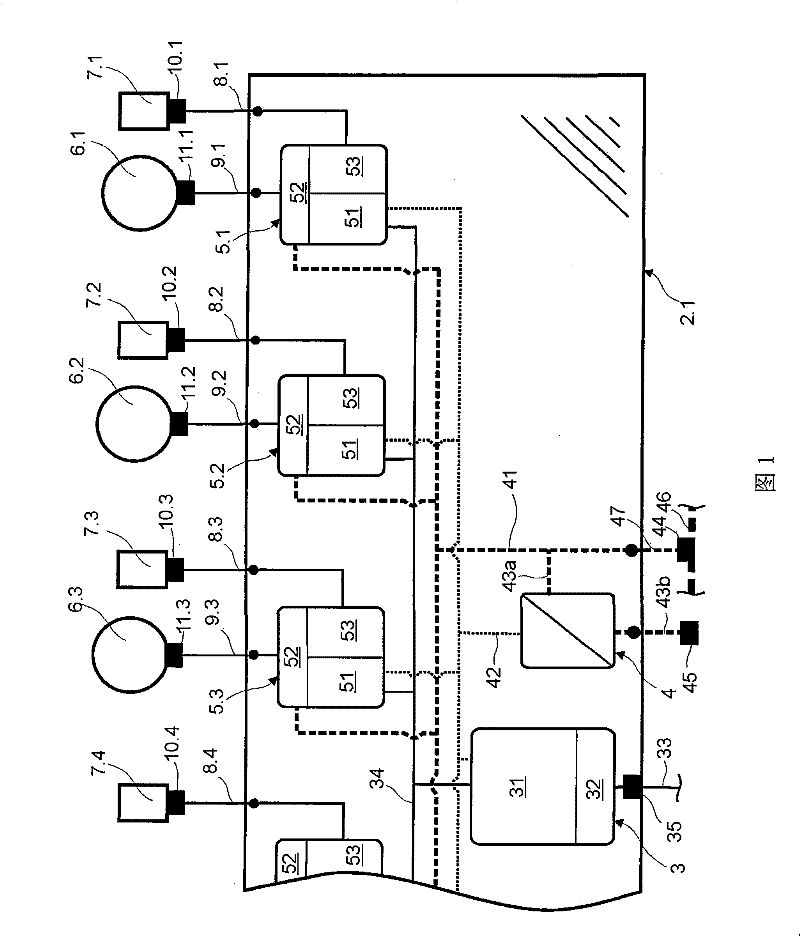

[0071] figure 1 A detail of a circuit board 2.1 according to the invention is shown. The circuit board 2.1 comprises a plurality of spindle drive electronics units 5.1, 5.2, 5.3 and partition electronics units 3, which are interconnected by data / signal lines 34 in the form of conductive strips. The sector electronics unit 3 is connected via a plug-in connection 35 to a data bus 33 to which a higher-level machine control (not shown) is connected.

[0072] The partition electronics unit 3 has a controller 31 and port electronics 32 . The spindle drive electronics units 5 . 1 , 5 . 2 , 5 . 3 likewise each have a controller 51 , port electronics 53 and power levels 52 . Connecting lines 8.1, 8.2, 8.3, 8.4 in the form of cable terminals with plug-in connectors 10.1, 10.2, 10.3, 10.4 are connected to the spindle drive electronics unit 5.1, 5.2, 5.3. The connection lines 8.1, 8.2, 8.3, 8.4 are connected to the manual switches 7.1, 7.2, 7.3, 7.4 via plug-in connections 10.1, 10.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com