Variable lateral force cavitator

A cavitation, lateral force technology, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, underwater operation equipment, ship construction, etc., can solve the problem of difficult implementation of control methods, and achieve simple structure and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

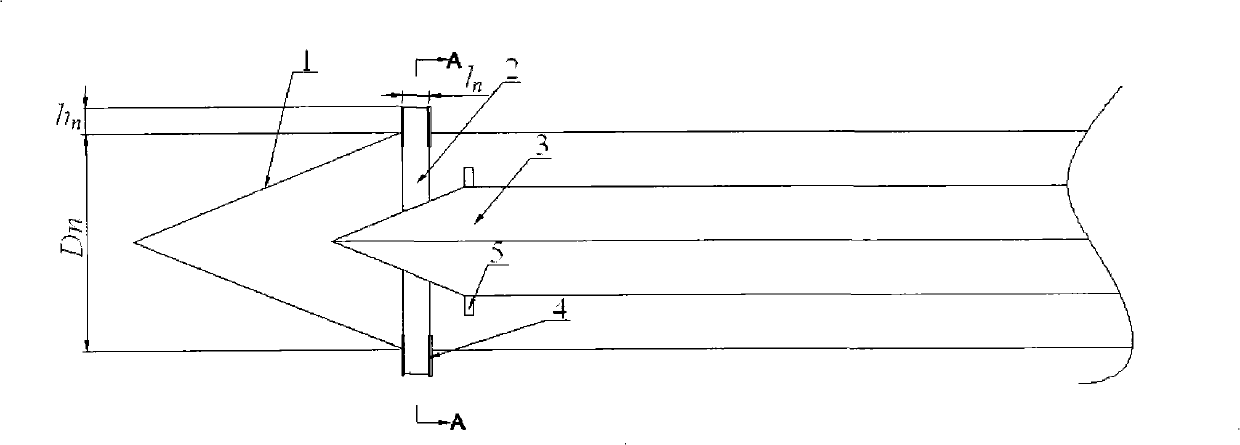

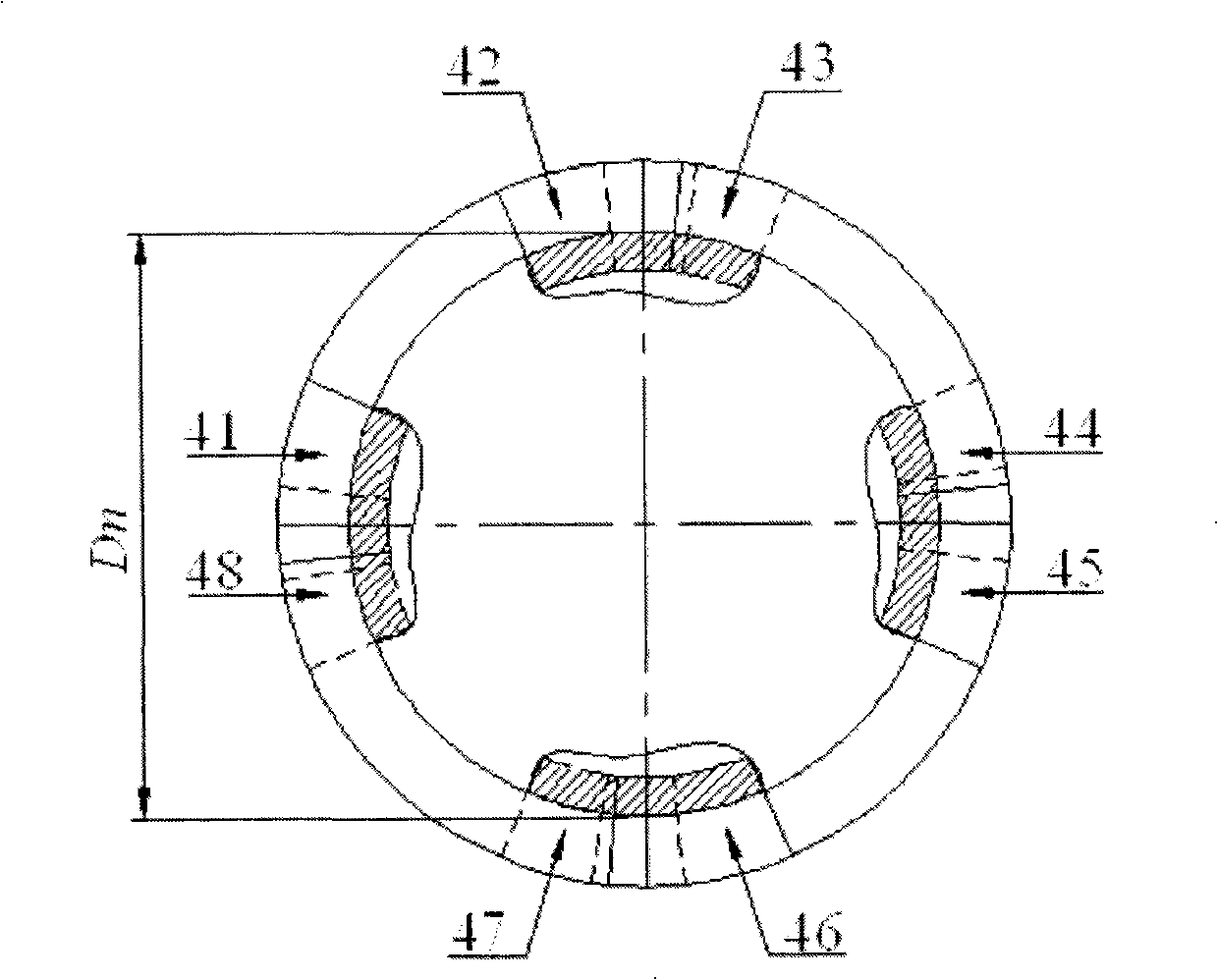

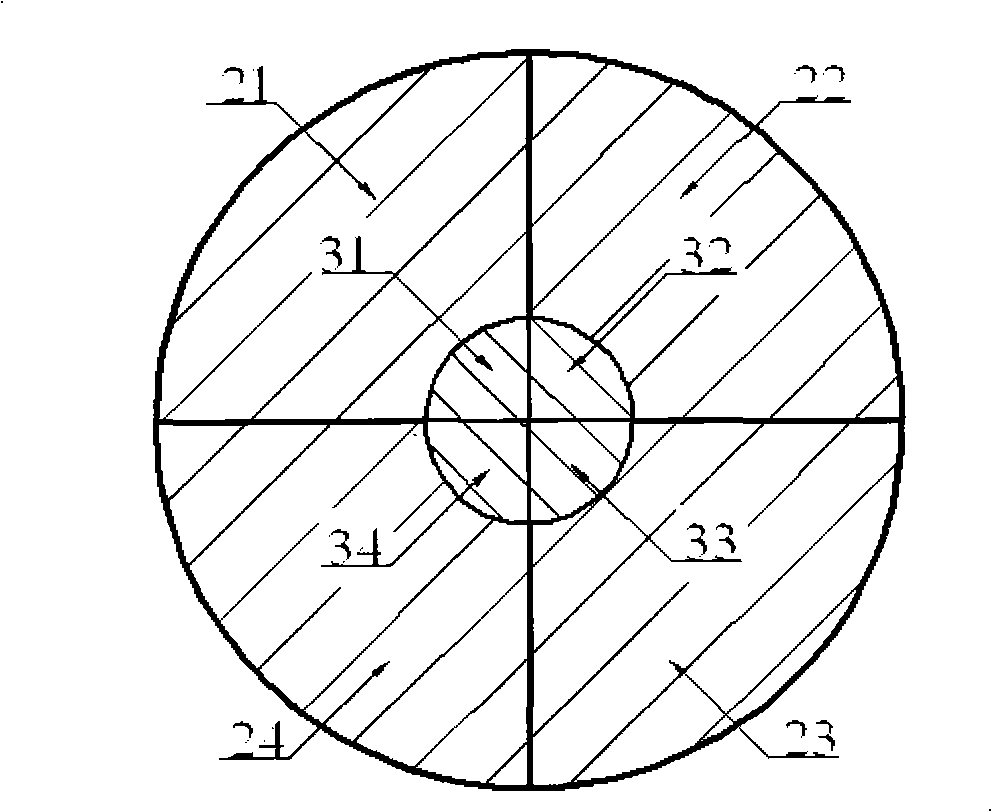

[0019] Referring to FIG. 1 , the composition of the variable lateral force cavitator of the present invention includes a front conical cavitator 1 , a control element 2 , a movable element 3 , a movable arc-shaped steel sheet 4 and an annular baffle 5 .

[0020] A movable element with a diameter smaller than Dn is installed in the front conical cavitator. The movable element is composed of a conical movable part and a cylindrical joystick. The four-lobe cylindrical joystick controls the lateral displacement of the four-lobe conical part respectively, thereby changing Circumferential displacement h of the control element n The value changes the effective working area of the cavitator, and then changes the size of the cavitation. When the displacement of any two sides of the movable element is inconsistent, the control element has asymmetry, and the conical cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com