Paint remover composition and method using same

A technology of composition and paint stripper, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of inability to use paint film, high toxicity, etc., and achieve the advantages of less environmental pollution, low cost and saving production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is used to illustrate the paint stripper composition provided by the invention.

[0022] Dissolve 40 grams of phenol in 360 grams of 40°C hot water, stir until fully dissolved, and then cool to 25°C. Add 50 grams of ethanol to the phenol solution, and finally add 50 grams of water, and stir well to obtain the paint remover composition T1.

Embodiment 2-6

[0024] These examples illustrate the paint stripper compositions provided by the present invention.

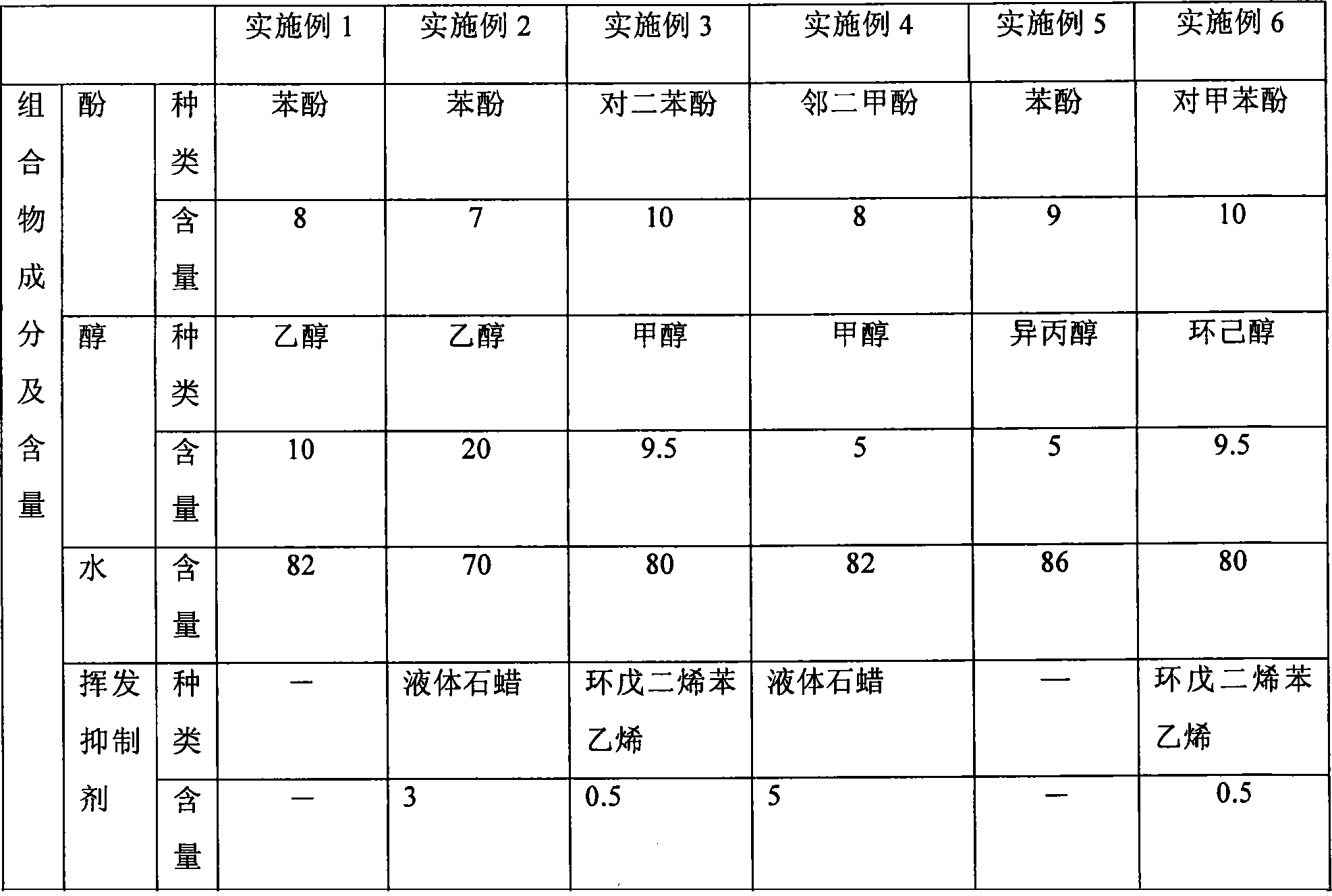

[0025] According to the same method and steps as in Example 1, paint remover compositions T2-T6 were respectively obtained, and their compositions are shown in Table 1.

Embodiment 7-12

[0033] These examples are used to illustrate the paint stripping method provided by the present invention.

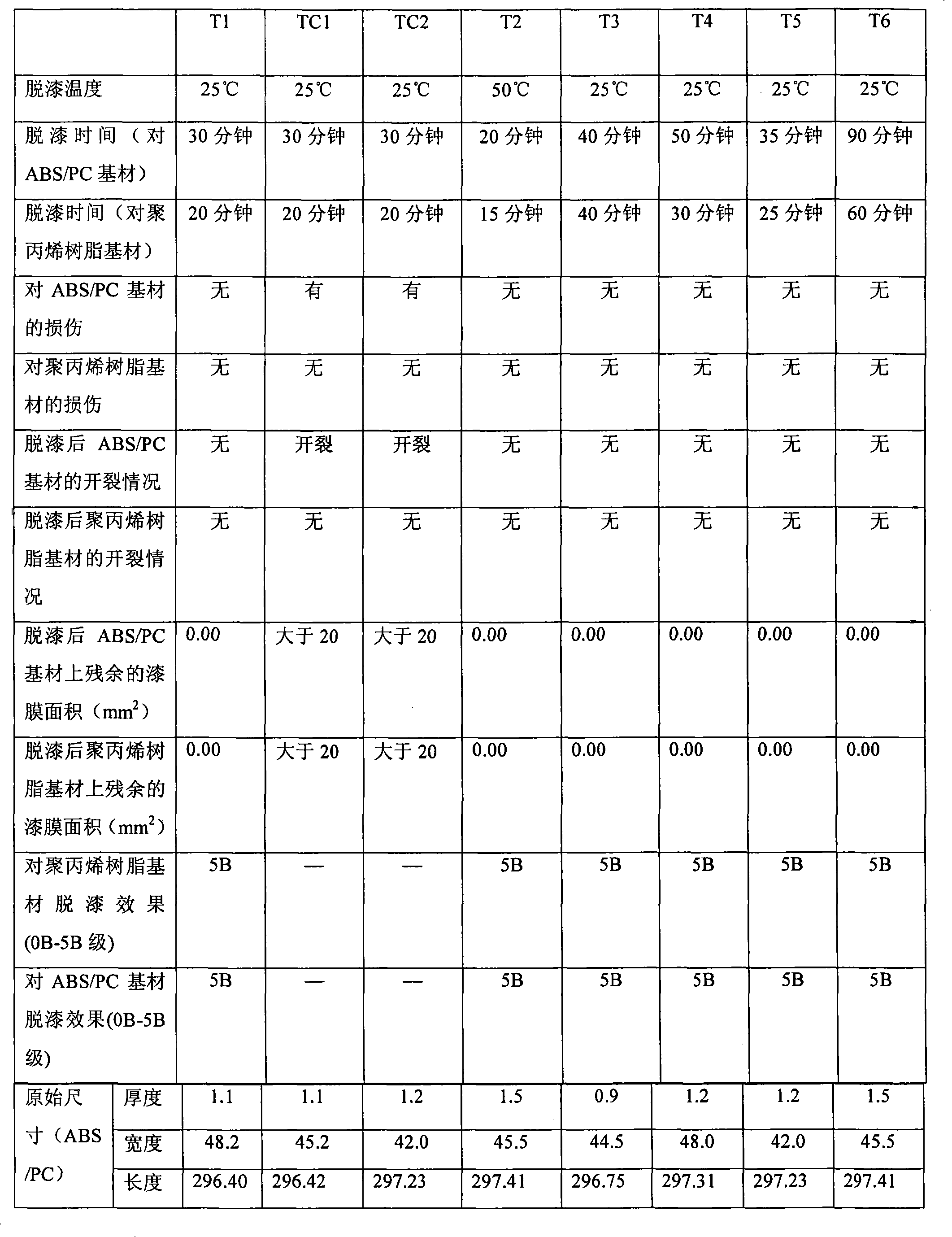

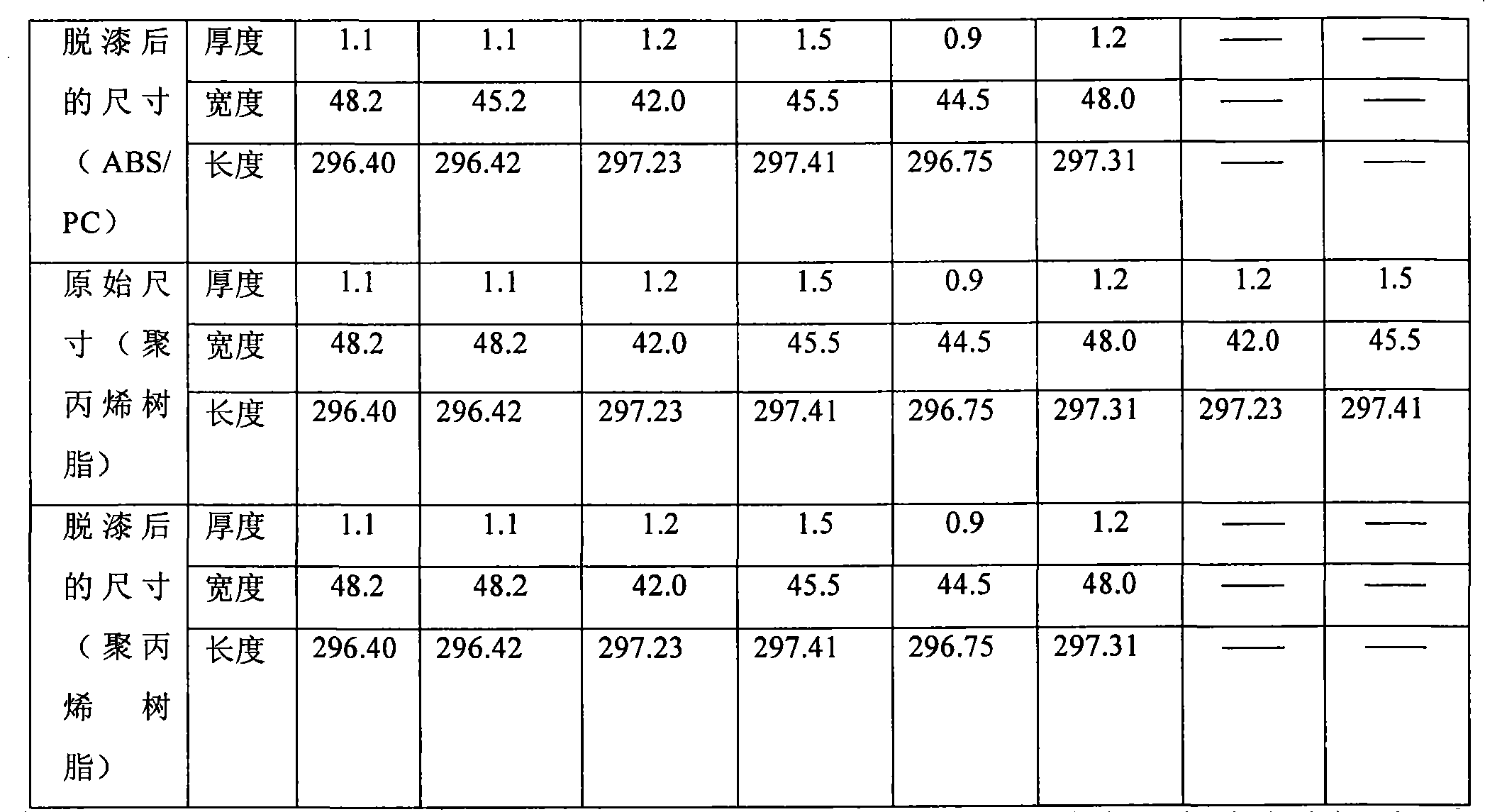

[0034] ABS / PC (manufacturer of ABS / PC is German Bayer company, model is FR86) substrate [45 (± 4mm) × 296.9 (± 0.5mm) × 1.2 (± 0.3 mm)] and polypropylene resin substrate [45 (± 4mm) × 296.9 (± 0.5mm) × 1.2 (± 0.3mm)] (manufacturer is South Korea SK, model is T131N) soaked in above-mentioned embodiment 1-6 respectively In the prepared paint remover compositions T1-T6, the paint was removed at the temperature shown in Table 2, and the time for removing the paint film was recorded. The results are shown in Table 2 below. The time for removing the paint film refers to the time elapsed from the time when the base material is soaked into the paint remover composition until the surface of the base material is observed with the naked eye until the paint film cannot be seen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com