Online predication method for concentration of export alkaline liquor of alumina evaporation device

A prediction method, a technology for evaporator outlets, applied in measuring devices, special data processing applications, instruments, etc., can solve problems such as hindering operation adjustment, difficult to analyze the evaporation capacity of evaporation equipment, and unable to calculate the evaporation capacity of intermediate equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

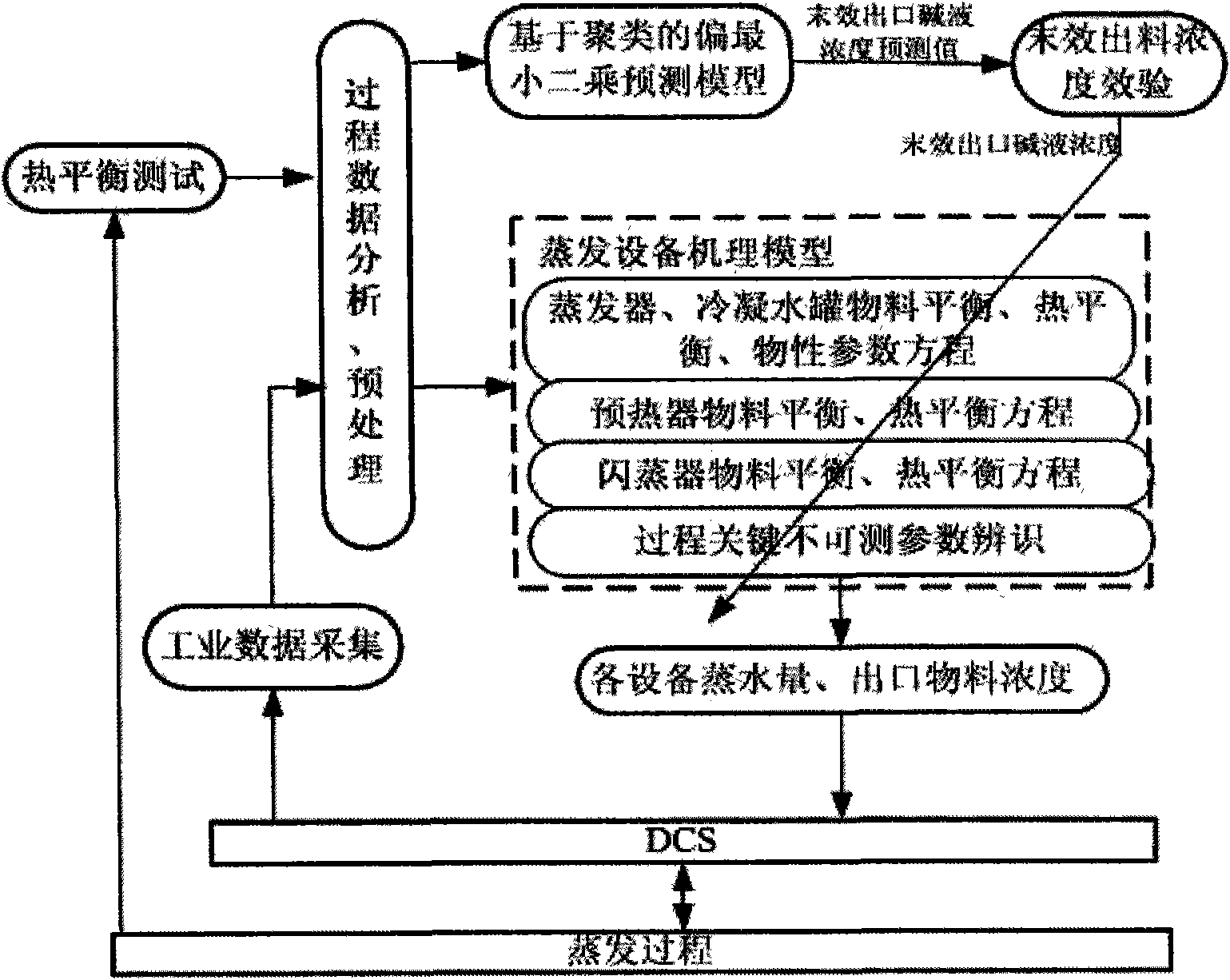

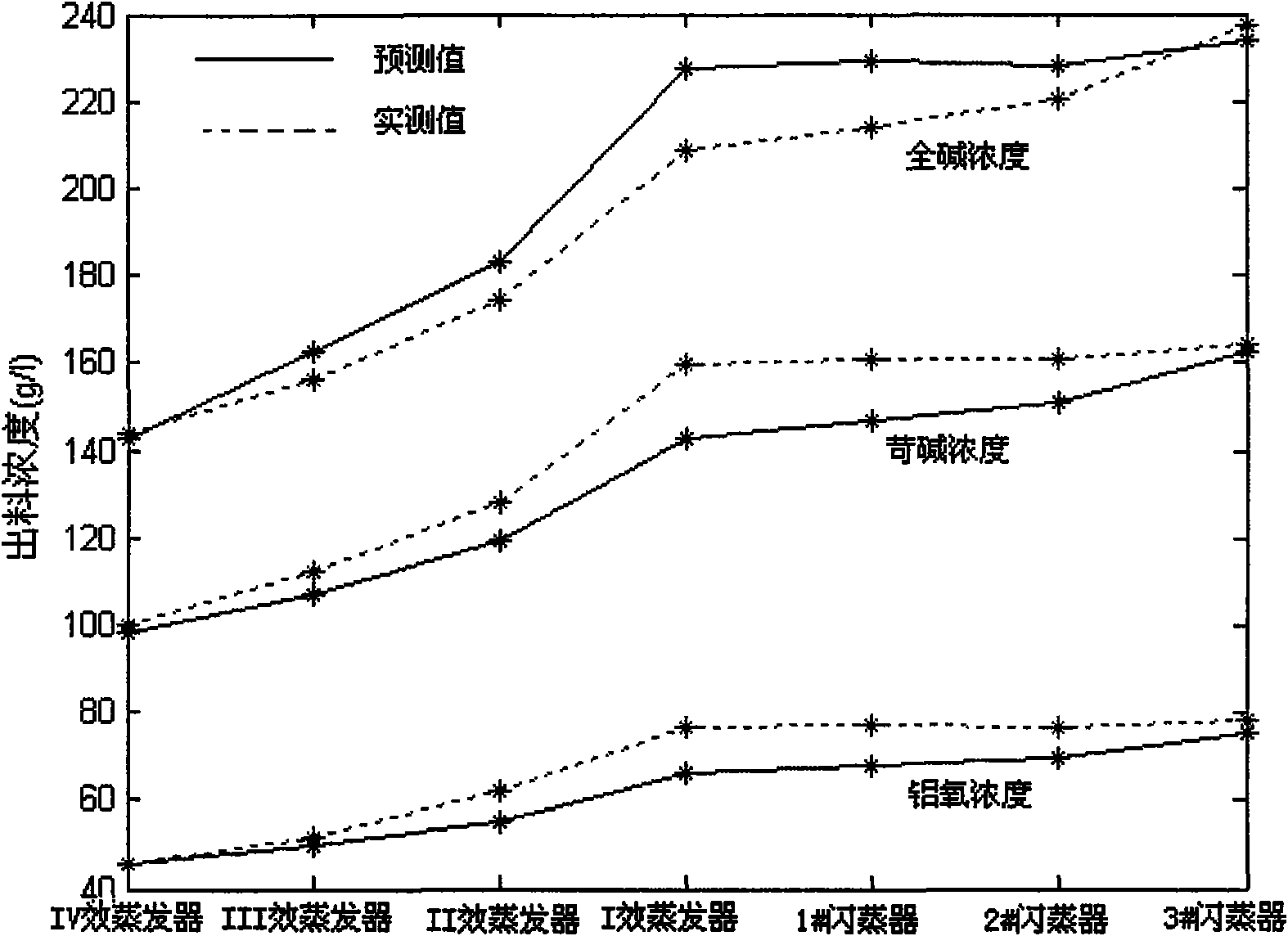

[0022] Such as figure 2 As shown, the present invention utilizes the mechanism model and the partial least squares model based on the clustering-based final effect outlet lye to respectively predict and verify the concentration of each equipment outlet lye and the final effect outlet lye concentration, and then predict the result by the mechanism model The correction to get the predicted value of the concentration of lye at the outlet of the evaporation process equipment.

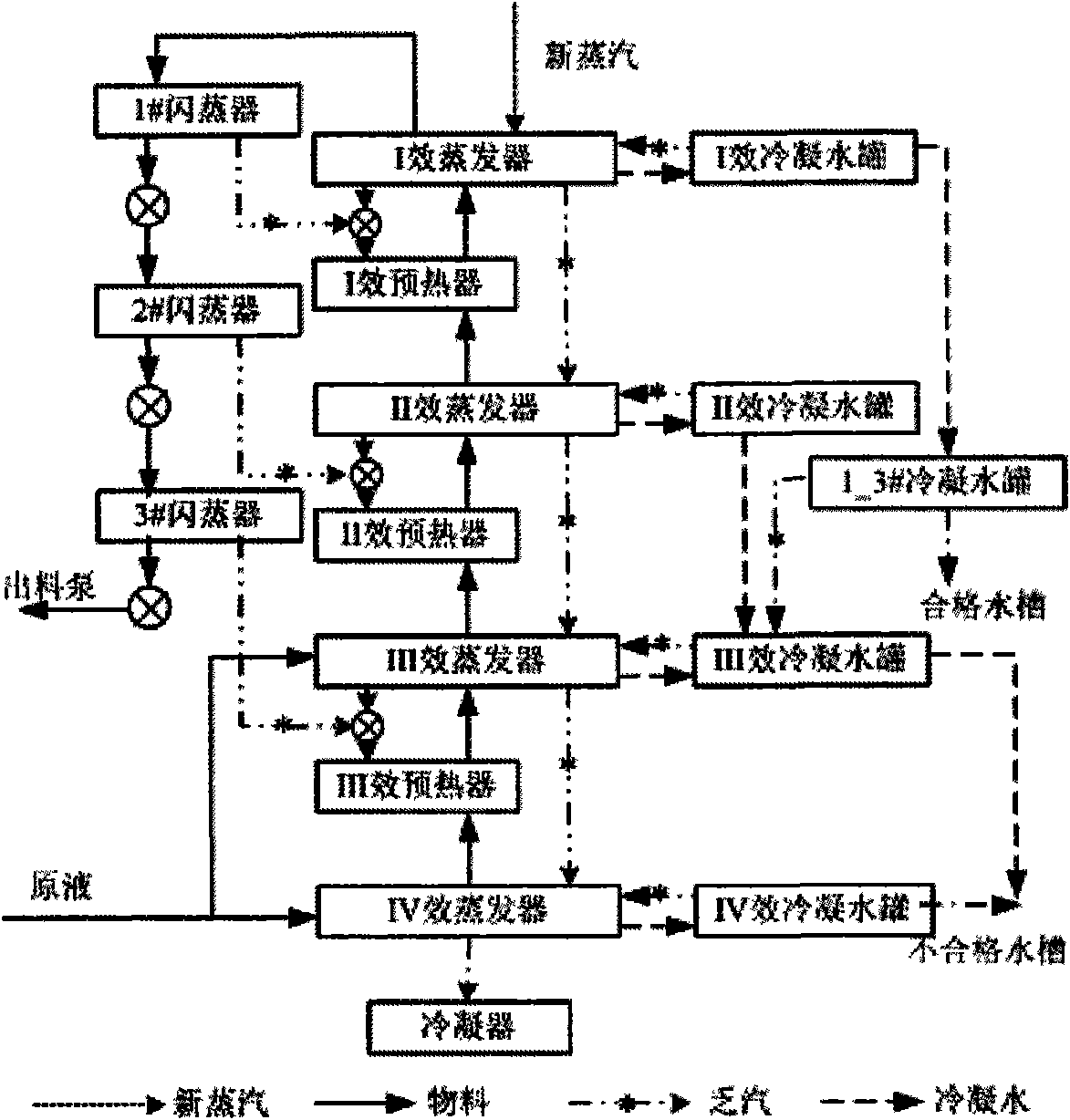

[0023] 1. Evaporation process equipment mechanism model

[0024] The main components of the material in the evaporation process include: Al 2 o 3 , NaOH, Na 2 CO 3 、H 2 O. The principle of the evaporation process can be summed up as: using heating to make the material boil, part of the water in the material is vaporized, and the concentration of other components in the material is increased. Regardless of the effects of scarring, solvent volatilization and other factors, the Al 2 o 3 , NaOH, Na 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com