Online predication method for concentration of export alkaline liquor of alumina evaporation device

A prediction method, a technology of evaporator outlet, applied in the direction of measuring devices, special data processing applications, instruments, etc., can solve the problems that the evaporation capacity of intermediate equipment cannot be calculated, the operation adjustment is hindered, and the evaporation capacity of evaporation equipment is difficult to analyze.

Inactive Publication Date: 2010-11-10

CENT SOUTH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the research is based on mechanism-based modeling or data-based modeling and analysis. Since the mechanism modeling method is based on certain assumptions, it can reflect the characteristics of each equipment. Due to the influence of uncertain factors, such as assumptions and actual conditions, there is a gap, leading to large prediction errors; while the data-based model can only reflect the uncertain nonlinear relationship between the final effect outlet material concentration and various process parameters and equipment status. It is impossible to calculate the evaporation capacity of intermediate equipment; it is difficult to accurately analyze the evaporation capacity of each evaporation equipment under the influence of uncertain factors in the actual production process, which hinders the operation adjustment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

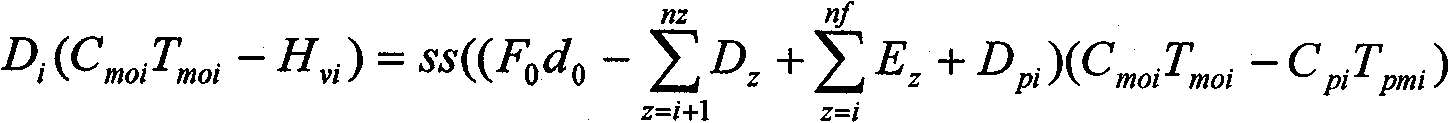

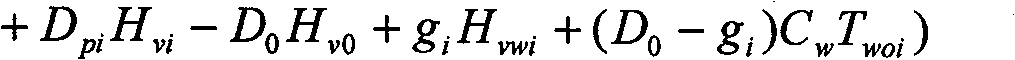

An online predication method for the concentration of export alkaline liquor of an alumina evaporation device is disclosed, the invention implements an establishment of an evaporation process device mechanism model based on the principles of material balance and energy balance subsequent to the analysis for evaporation process technologies, operating status and related factors that impacts on theconcentration of export materials of apparatuses; and on the basis of the classification of historic working condition data, the invention establishes a partial least square model of the concentrationof final-effect alkaline liquor based on fuzzy clustering. The invention predicates the concentration of the export materials of the principal unit apparatuses by implement online correction on key parameters in the mechanism model on the basis of the concentration of the final-effect alkaline liquor. The model efficiently solves the problem that the concentration of the export materials of the apparatuses is hardly detected online, and is important to operation and optimization guidance of the entire evaporation process.

Description

An Online Prediction Method of Alkali Concentration at the Outlet of Alumina Evaporation Equipment technical field The invention relates to an online prediction method of key parameters of complex production process equipment, in particular to the prediction of the alkali liquor concentration at the outlet of alumina evaporation equipment. Background technique The evaporation process is an essential key process to maintain the balance of alkali concentration and remove salt and impurities in the alumina production process. For the evaporation of the carbon separation mother liquor of the sintering method, the caustic concentration must be guaranteed to be between 150 and 170g / l. In actual production, the operator adjusts the process parameters of the evaporation process according to the final effect outlet material concentration of the test, so as to realize the evaporation process. On-line control to ensure output and quality. However, the concentration of the material a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06F17/50G01N33/00

Inventor 桂卫华阳春华柴琴琴朱红求胡志坤

Owner CENT SOUTH UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com