High-efficient retroreflective microprism and manufacturing method of mold thereof

A micro-prism and retro-reflection technology, applied in prisms, optics, instruments, etc., can solve the problems of complex processing process, low processing efficiency and precision, and achieve the effect of simple structure and shape, easy implementation, and improved retro-reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

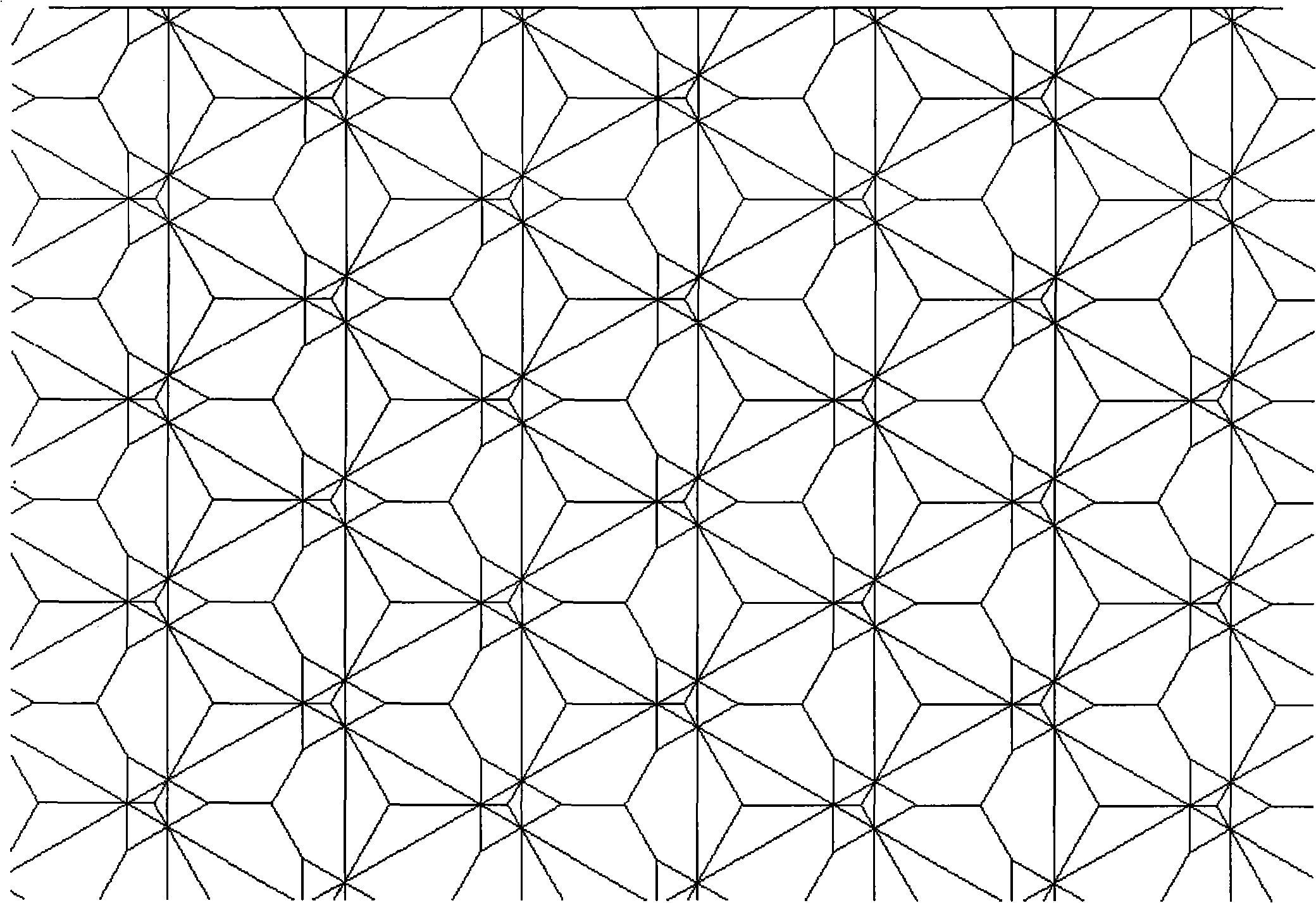

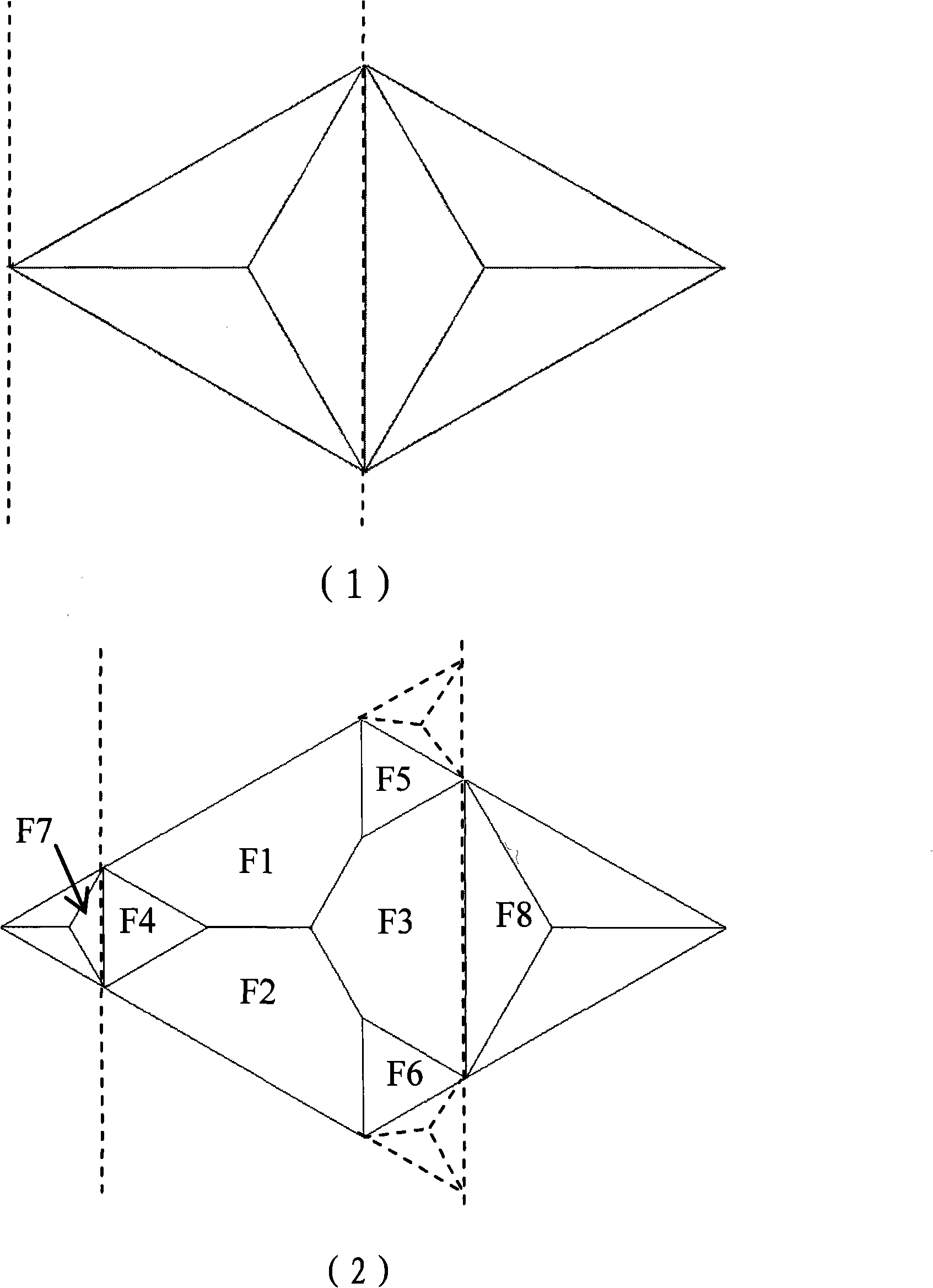

[0036] Microprism retroreflective structure of the present invention such as figure 1 shown. figure 2 (1) It is two adjacent unit structures of ordinary microprisms, which are composed of two regular triangular pyramids, the bottom surface is an equilateral triangle, and the three sides are isosceles triangles, which are perpendicular to each other at the apex of the structure. Proximal side angle = 70.5288°. In contrast, a unit structure of the present invention such as figure 2 As shown in (2), it consists of two regular triangular pyramids and a symmetrical hexagonal pyramid. The two regular triangular pyramids still have: the base is a regular triangle, and the three sides are isosceles triangles, perpendicular to each other at the apex of the structure. The shape of the symmetrical hexagonal pyramid can be regarded as the three corners of the regular triangular pyramid being vertically truncated by the triangular shape with an angle of 70.5288°, and the remaining pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com