Levitation traction integrated system for high-efficiency magnetic-levitation train

A technology for maglev trains and integrated systems, applied in electric traction, electric vehicles, vehicle components, etc., can solve problems such as increased suspension burden, interference, and low motor work efficiency, so as to reduce the cost of train construction and subsequent operation and maintenance costs, and reduce manufacturing costs. Accuracy requirements, the effect that is conducive to operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be further described in detail with reference to specific embodiments and the accompanying drawings of the specification.

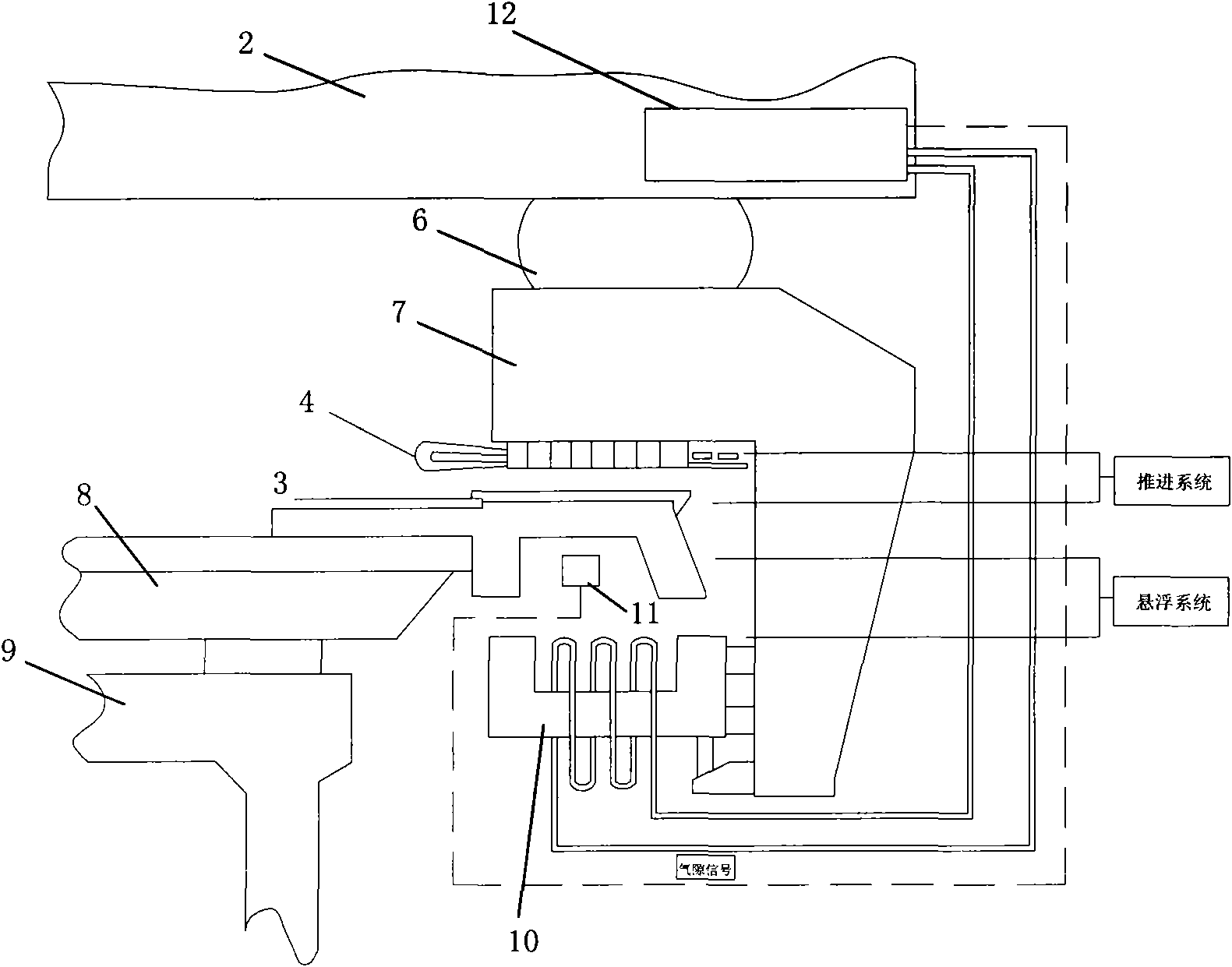

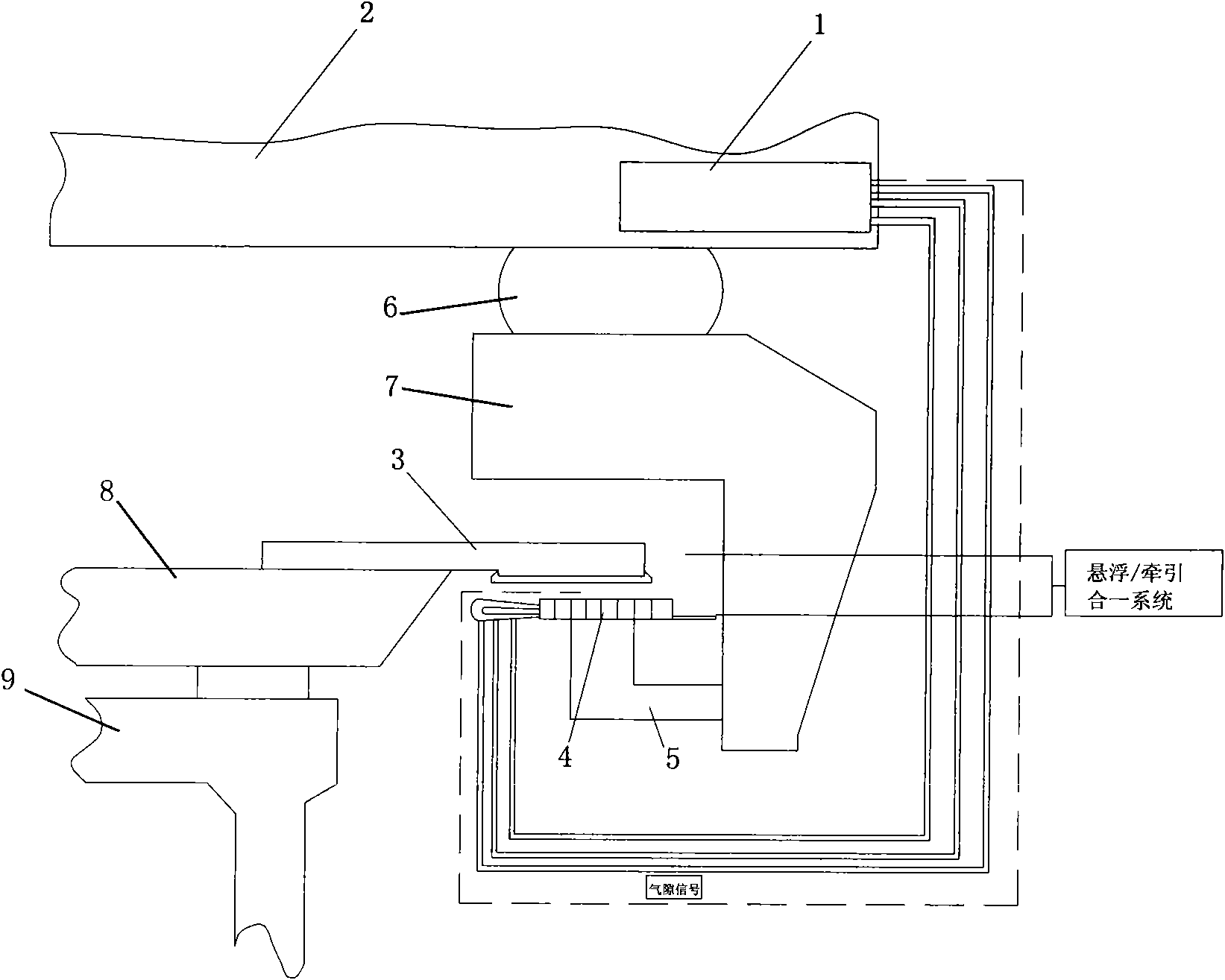

[0027] Such as image 3 Shown here is the integrated levitation traction system for high-efficiency maglev trains of the present invention. It includes a levitation traction controller 1, a linear induction motor, a linear induction motor support beam 5, and a power supply. The linear induction motor includes a linear induction motor primary 4 and a linear induction motor. The motor secondary 3, the levitation traction controller 1, the linear induction motor primary 4 and the power supply are fixed on the car body 2 to move together with the train, and the linear induction motor primary 4 is located under the track, and the linear induction motor primary 4 passes through the linear induction motor The support beam 5 supports and fixes. The secondary 3 of the linear induction motor is laid along the track in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com