Hot-continuous-rolling strip steel side guide with heating function

A technology of hot continuous rolling and strip steel, which is applied in metal rolling, guiding/positioning/aligning devices, etc., can solve the problems of product quality reduction, edge cracking, plasticity decline of intermediate billets, etc., achieving obvious effect and preventing edge cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

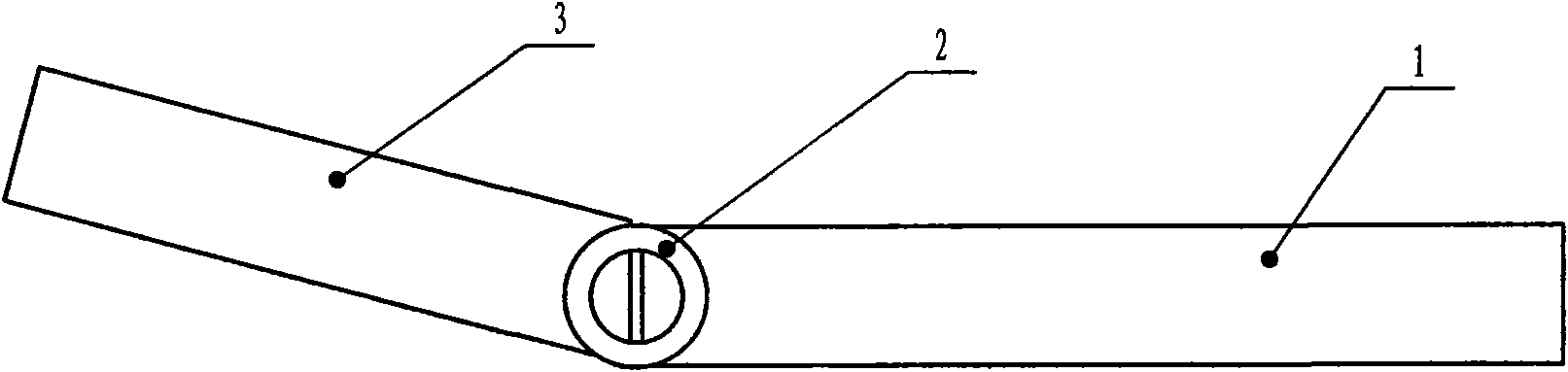

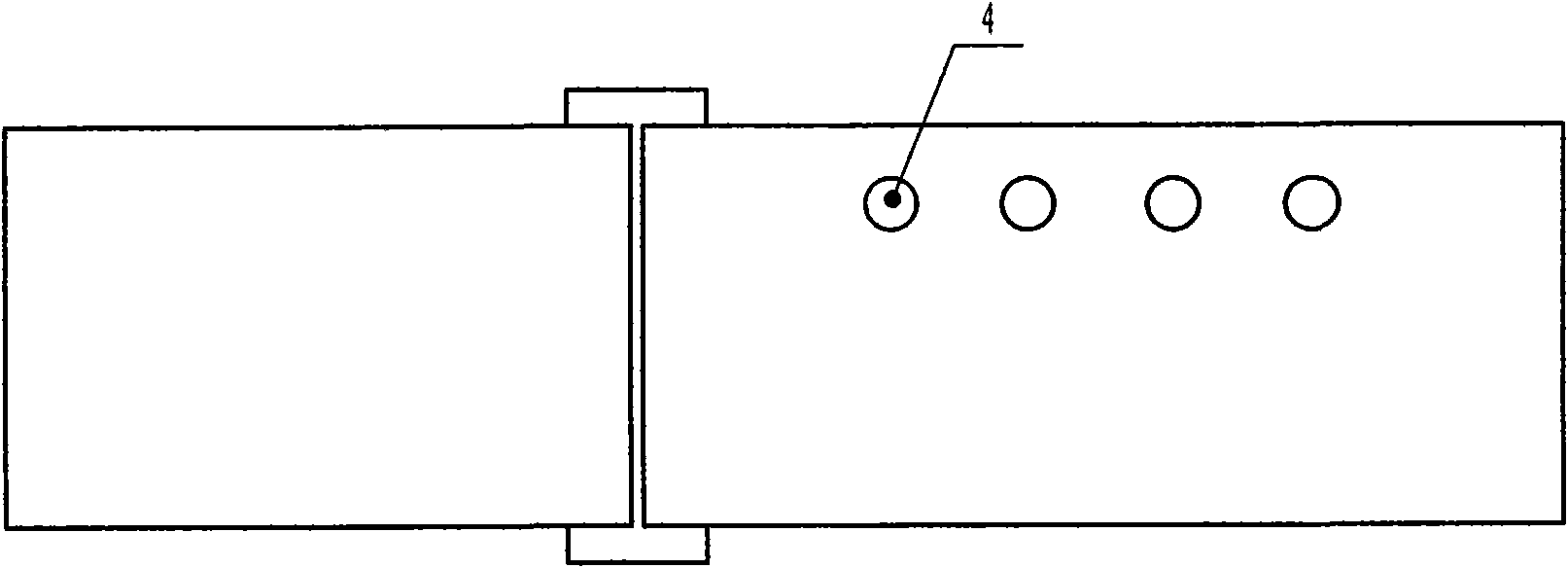

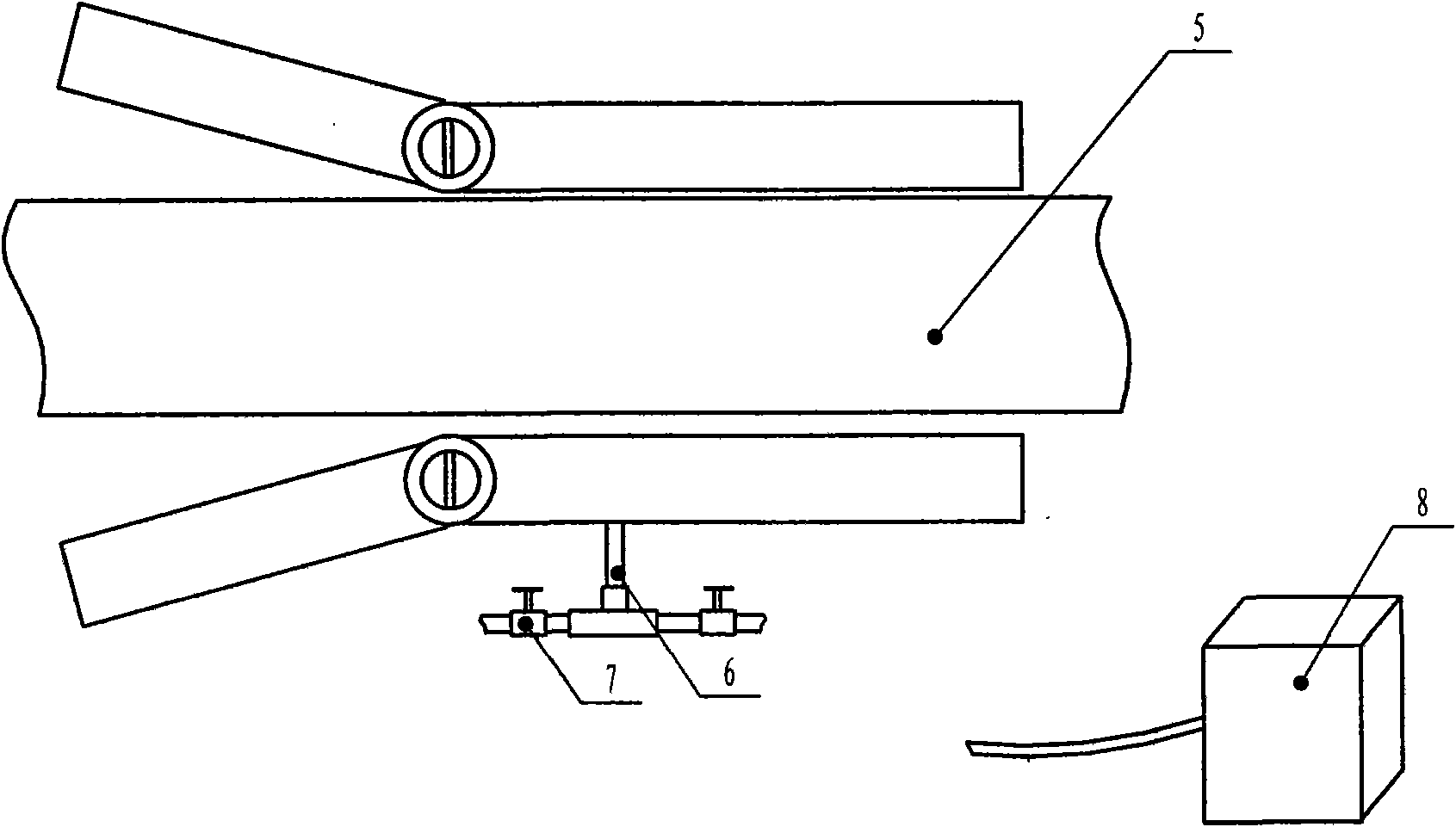

[0014] Embodiment one: figure 1 , figure 2 , image 3 As shown, this embodiment includes two rectangular metal blocks 1, 3, the angle between the two rectangular metal blocks is 130 degrees, and the two rectangular metal blocks are fixedly connected by a connecting piece 2. Four burners 4 are fixedly arranged on the top, and the burners 4 are connected with gas, and the gas is transported through the gas pipeline 6, and the valve 7 is set on the gas pipeline 6, and the valve 7 is controlled by the PLC-300 control system 8.

Embodiment 2

[0015] Embodiment 2: In this embodiment, several burners are installed inside the existing side guide and gas pipelines are connected, that is, several grooves are opened on the side of the existing side guide adjacent to the billet, and several burners are burnt. The nozzles are fixedly installed in these grooves, and the air duct is passed through the existing side guide, and the burners are all communicated with the air duct, and other structures are the same as in the first embodiment.

[0016] The burner (that is, the combustion device) can be a complex burner or a simple burner, as long as it can realize that the gas can be combusted, it is the MBG100 type used in the above-mentioned embodiments.

[0017] The complex burner includes ignition electrode and flame monitoring probe, combustion air blower, fuel pressurization pipe, ignition monitoring control device, combustion air pipe.

[0018] A simple burner is a simple gas nozzle and igniter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com