Preparation method for low-viscosity sodium carboxymethyl cellulose for foodstuff

A technology of sodium carboxymethyl cellulose and low viscosity, which is applied in the field of polymer chemistry, can solve the problems of poor performance of cellulose pulp or wood pulp cellulose, difficult post-processing technology, and high price of isopropanol, and achieves the goal of preparing The method is simple, the effect of thickening and improving the taste of food, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

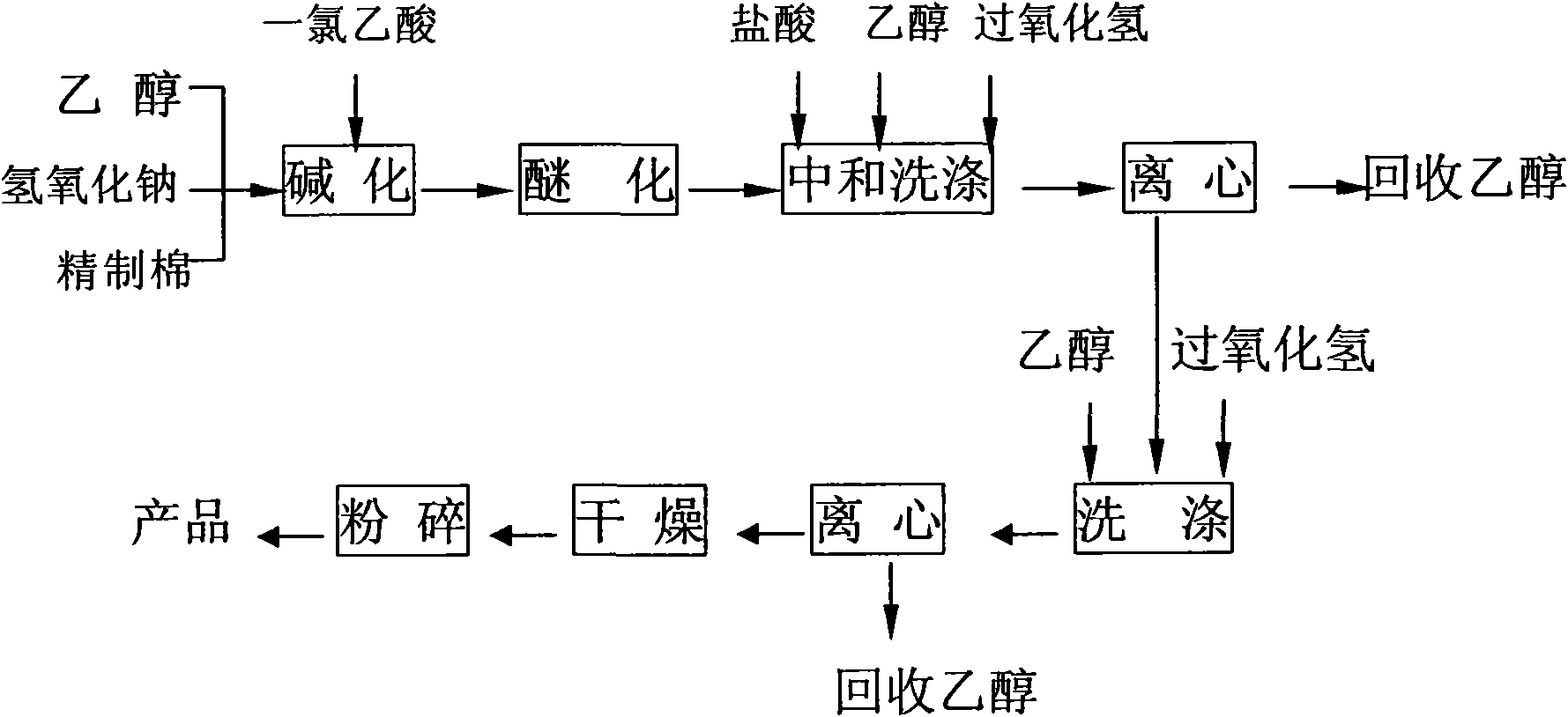

Image

Examples

Embodiment 1

[0019] Under the reaction condition of 20 ℃, the solvent mixture of 126 parts of 52% sodium hydroxide aqueous solution and 240 parts of 92% (volume) ethanol is mixed with 120 parts of flake-shaped refined cotton cellulose (average degree of polymerization is 2000) in 10 minutes ) into the alkalization machine evenly at the same time, and alkalization reaction under stirring for 50 minutes, uniformly added 113 parts of 65% ethanol solution of monochloroacetic acid within 50 minutes, and slowly heated up to 75 ° C and stirred for etherification reaction for 100 minutes; Add 8 parts of 15% hydrochloric acid to neutralize excess sodium hydroxide, wash with 2800 parts of 76% (volume) ethanol aqueous solution for 45 minutes, add 6 parts of 27.5% hydrogen peroxide aqueous solution while washing, centrifuge to separate ethanol aqueous solution, centrifuge After the material was washed again with 4000 parts of 70% (volume) ethanol aqueous solution for 35 minutes, 12 parts of 27.5% hydro...

Embodiment 2

[0024] Under the reaction condition of 40 ℃, with 137 parts of 48% sodium hydroxide aqueous solution and the solvent mixture of 300 parts of 96% (volume) ethanol in 20 minutes with 120 parts of flake-shaped refined cotton cellulose (average degree of polymerization is 500 ) into the alkalization machine evenly at the same time, and alkalization reaction under stirring for 80 minutes, uniformly added 102 parts of 75% ethanol solution of monochloroacetic acid within 20 minutes, and slowly warming up to 80° C. and stirring for etherification reaction for 50 minutes; Add 2 parts of 25% hydrochloric acid to neutralize excess sodium hydroxide, wash with 3200 parts of 75% (volume) ethanol aqueous solution for 40 minutes, add 10 parts of 27.5% hydrogen peroxide aqueous solution at the same time, centrifuge to separate ethanol aqueous solution, centrifuge After the material was washed again with 3800 parts of 72% (volume) ethanol aqueous solution for 45 minutes, 12 parts of 27.5% hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com