Photomagnetically coded electronic tag, real-time equipment monitoring and engine frame positioning system and real-time equipment monitoring and engine frame positioning method

A technology of electronic tags and magnetic encoding, applied in radio wave measurement systems, electromagnetic radiation induction, computer components, etc., can solve the problems of increased cost and implementation difficulty, huge cost of manufacturing and installation, loss of real-time monitoring effect, etc., to achieve Perfect real-time monitoring and rack and shelf positioning function, extended service life, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

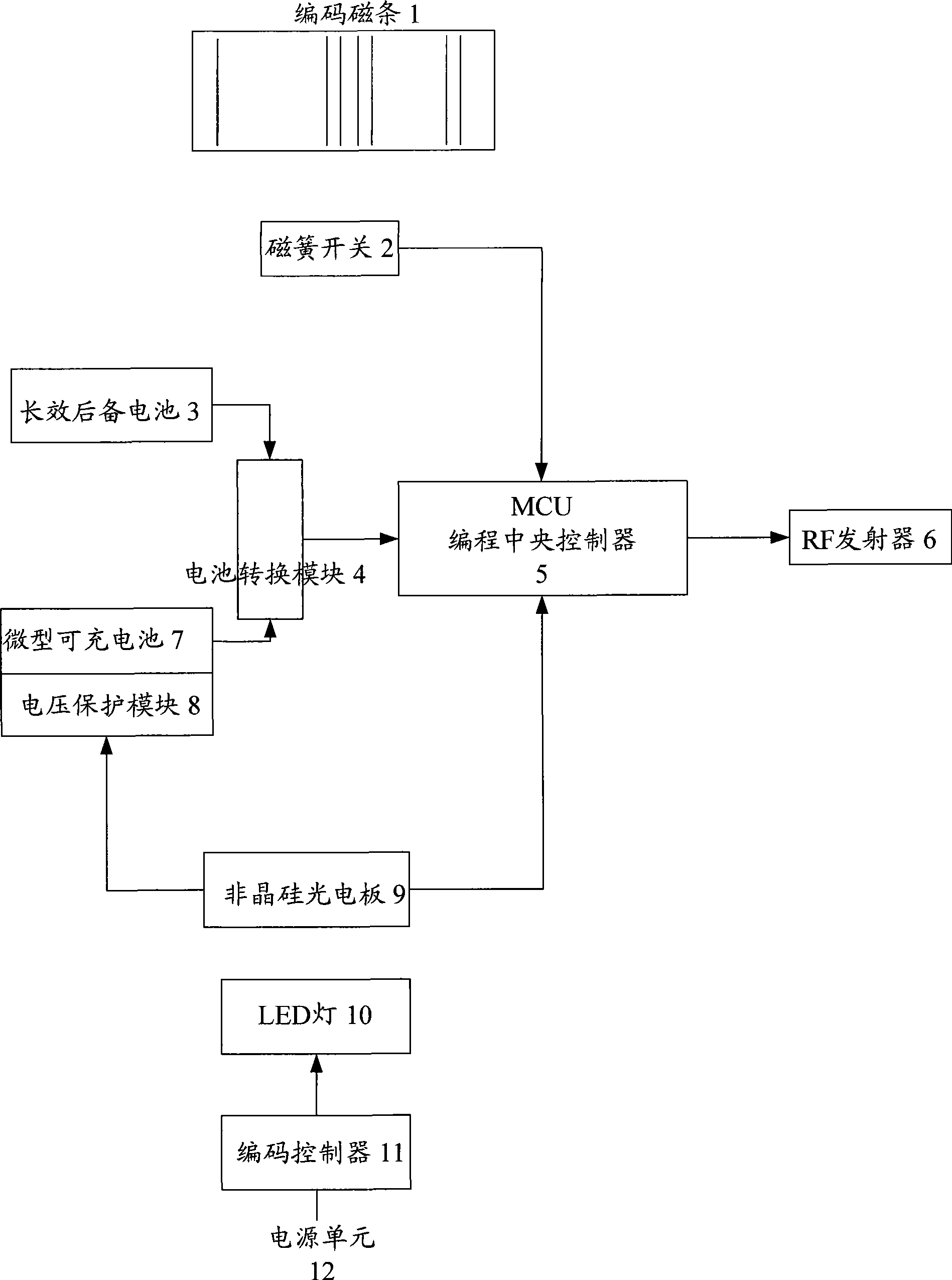

[0034] see figure 1 As shown, the optical-magnetic encoded electronic tag includes an RFID transmitter 6, an antenna, a central controller 5 and a power module, and the power module is connected to the antenna through the central controller 5 and the RFID transmitter 6 in turn , wherein, the electronic tag also includes a magnetic induction device 2 and an optical induction device 9, the magnetic induction device 2 and the optical induction device 9 are respectively connected to the central controller 5, and the power supply module includes a rechargeable battery unit, backup battery 3 and battery conversion unit 4, the light sensing device 9 is connected to the rechargeable battery unit, and the rechargeable battery unit and backup battery 3 are respectively connected to the battery conversion unit 4 The central controller 5 described above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com