Ground conveying machinery operated by rudder stock

A ground transportation and mechanical technology, applied in the direction of motor vehicles, transportation and packaging, lifting devices, etc., can solve the problems of structural consumption, high manufacturing cost of ground transportation machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

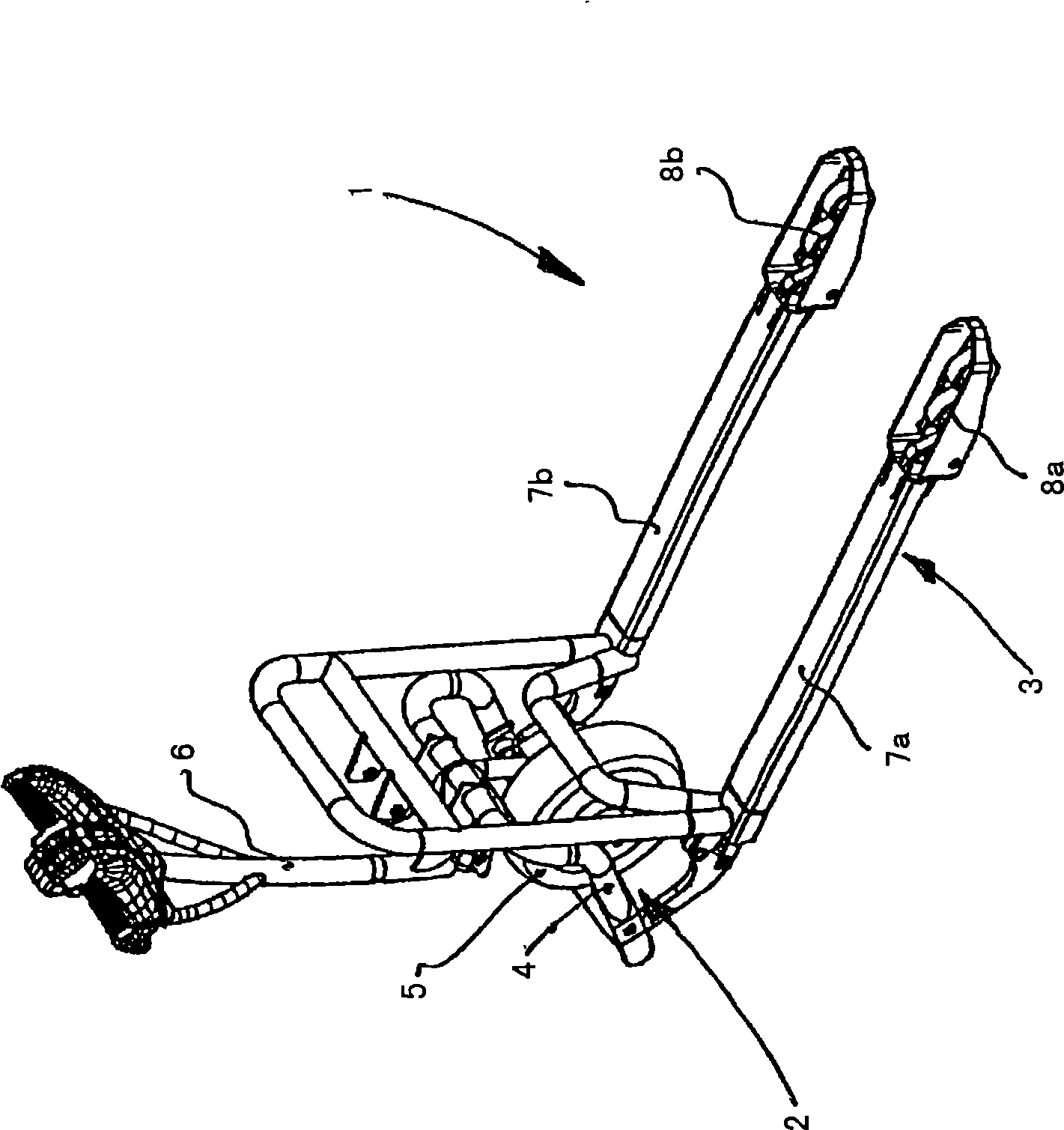

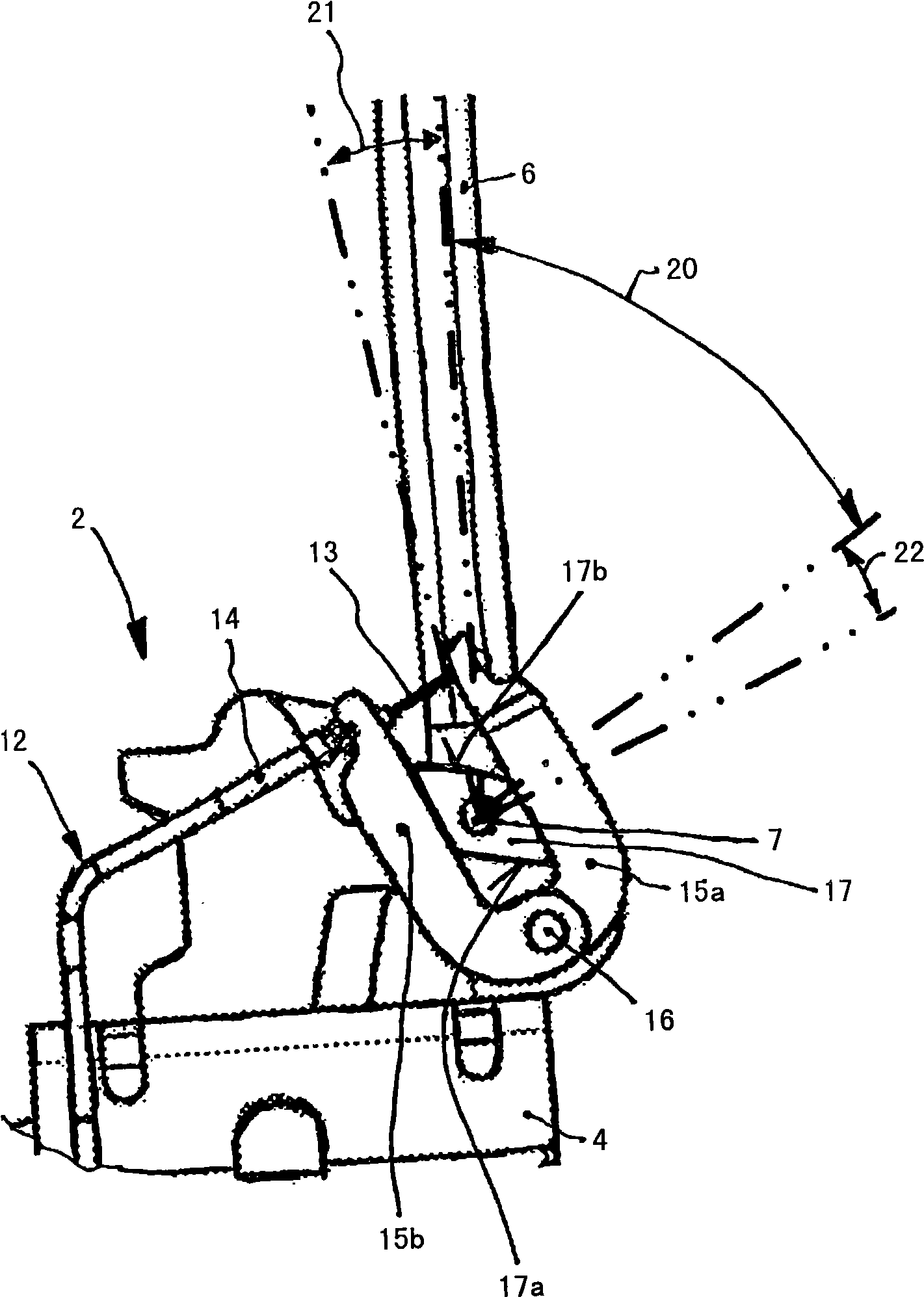

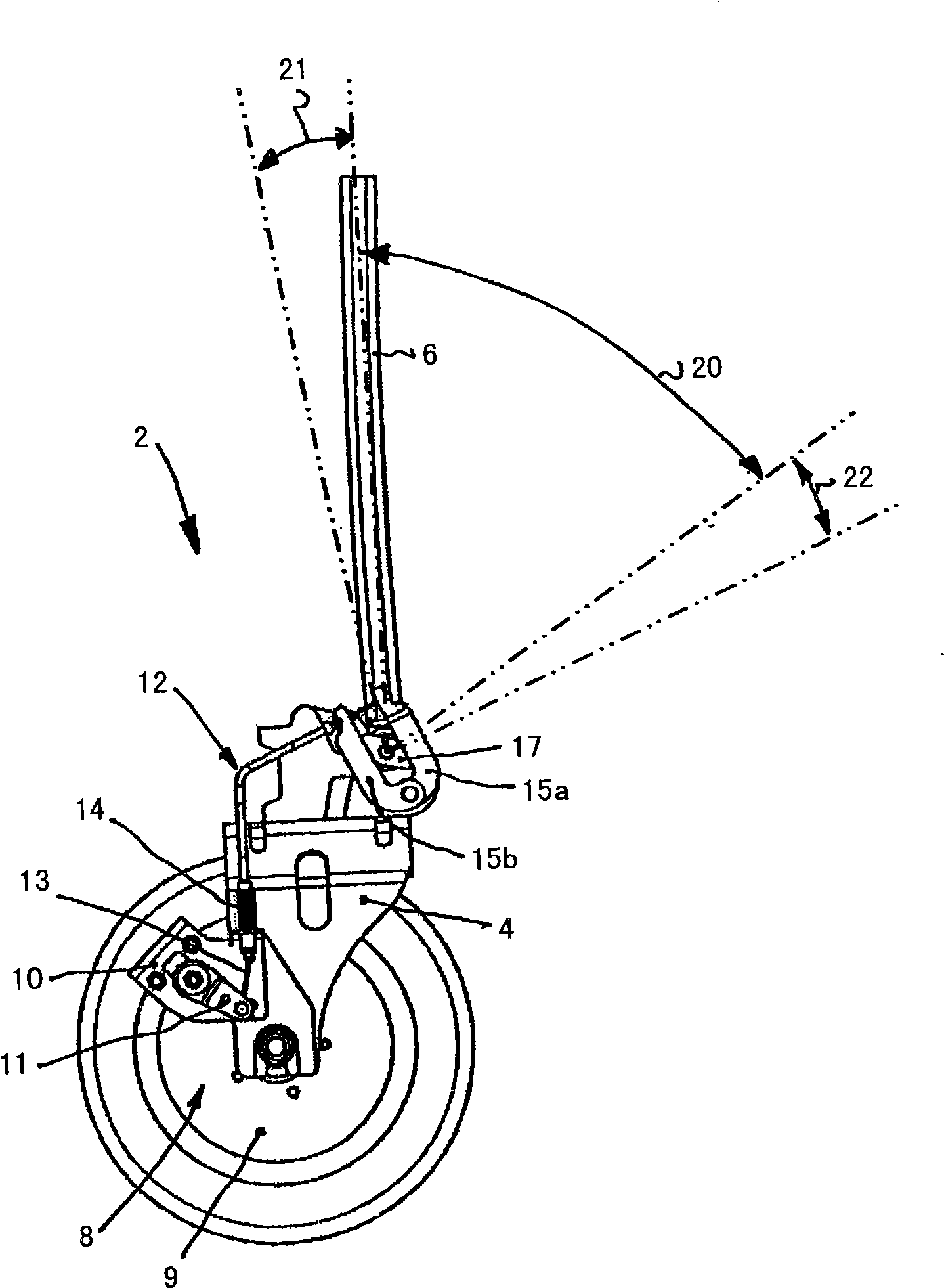

[0021] exist figure 1 In FIG. 1 , a tiller-operated floor conveyor 1 according to the invention is shown, for example in the form of a low-travel lift truck. The floor conveyor 1 has a drive part 2 and a load part 3 which is movable vertically relative to the drive part 2 in a manner which will not be described again. The drive 2 comprises a bow-shaped frame section 4 on which a drive wheel 5 is arranged so as to be steerable about a vertical axis of rotation. The steering of the lift truck 1 takes place by means of a tiller 6 connected to the drive wheels 5 . The drive wheel 5 can here be designed as a pneumatic-tyred drive wheel.

[0022] Two load arms 7a, 7b belonging to the load section 3 are supported on the road surface by means of load rollers 8a, 8b which can be raised and lowered vertically, wherein the load arms 7a, 7b can receive, lift and transport loads such as pallets, grid boxes or smalls containers.

[0023] Here, the drive part 2 and the load part 3 are fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap