Line-type thermal printer

A thermal printer and thermal print head technology, used in printing, transfer materials, power transmission devices, etc., can solve the problems of sufficient separation and inability to line thermal print heads, and achieve the effect of reducing torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of a line thermal printer to which the present invention is applied will be described below with reference to the drawings.

[0033] (the whole frame)

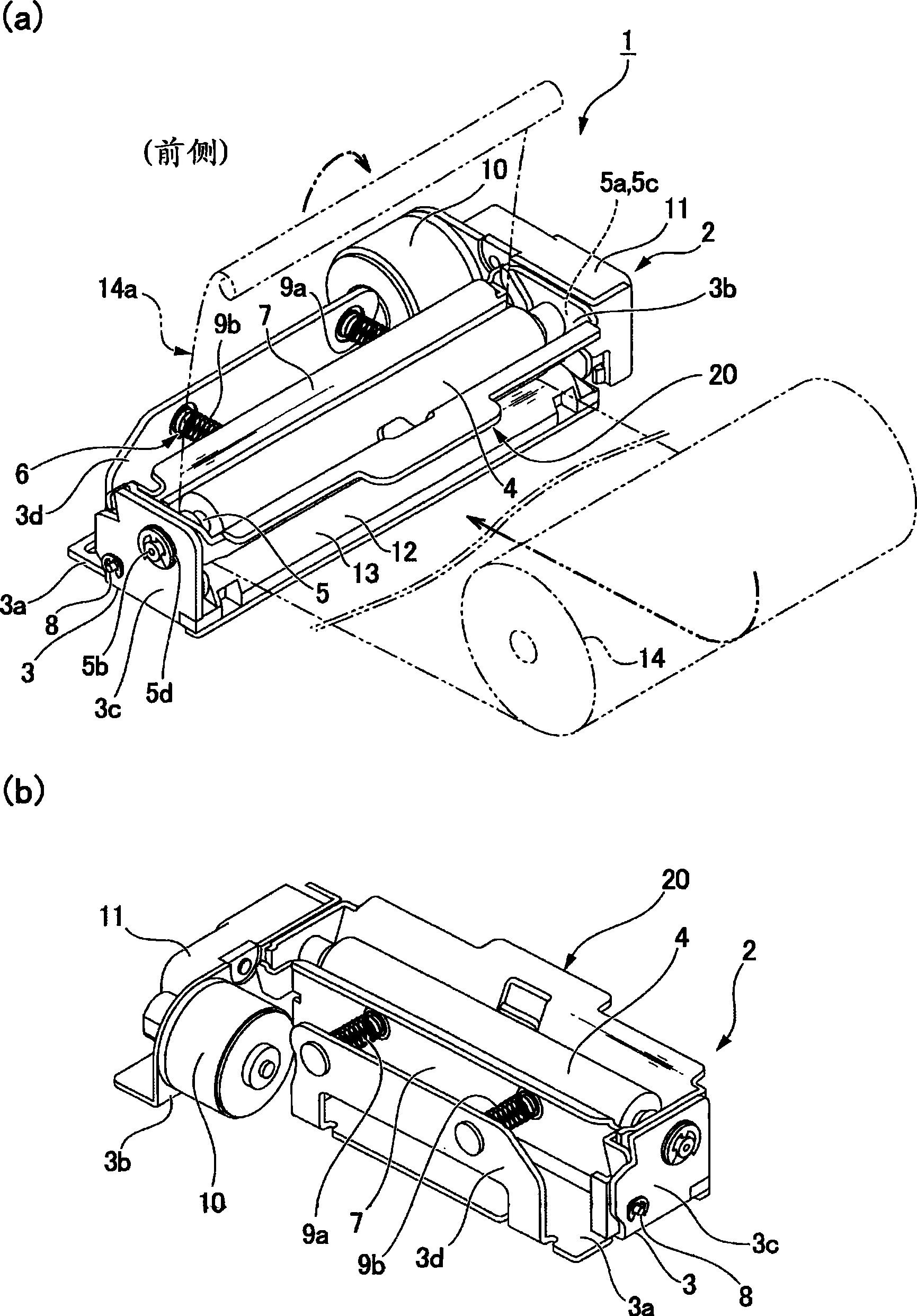

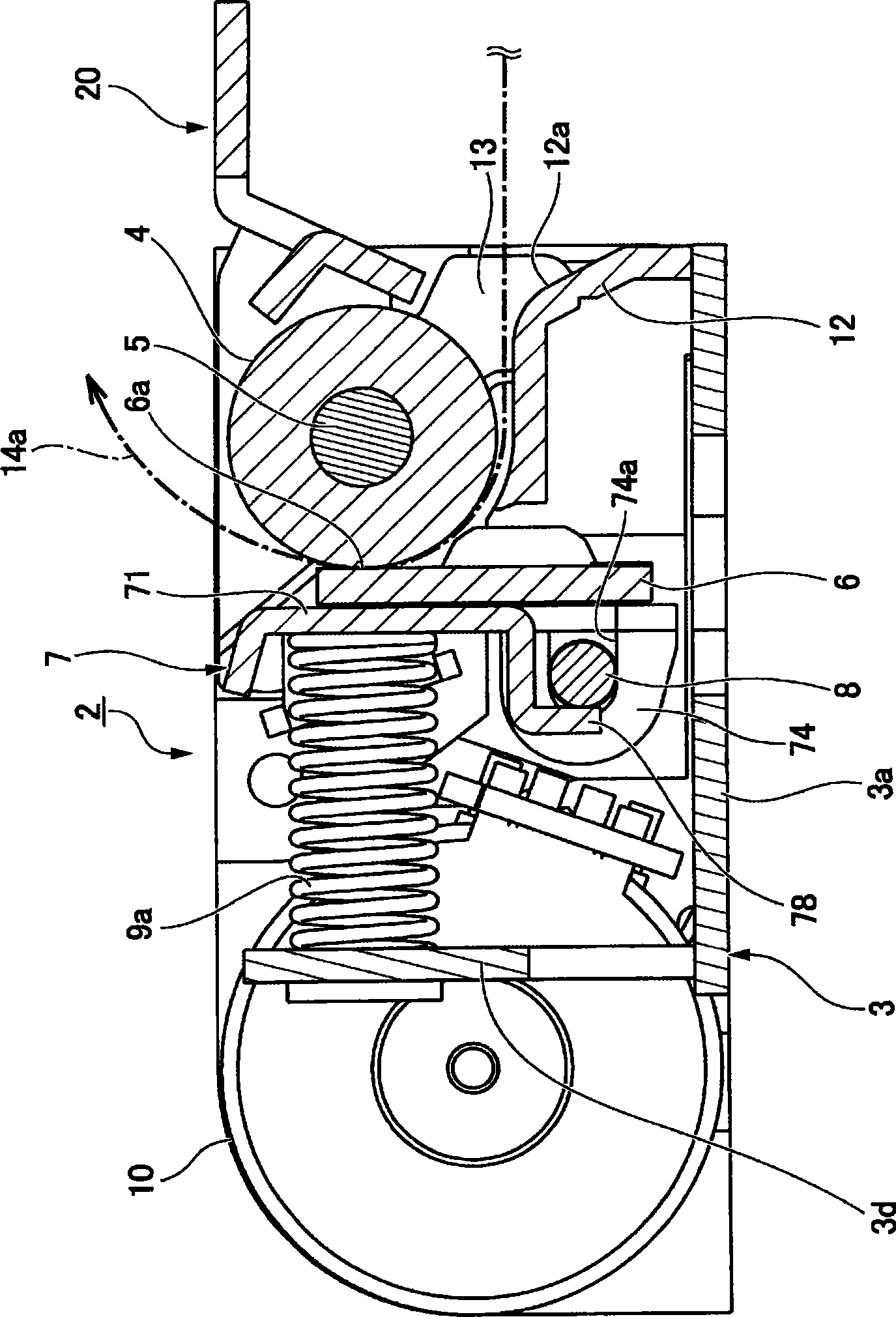

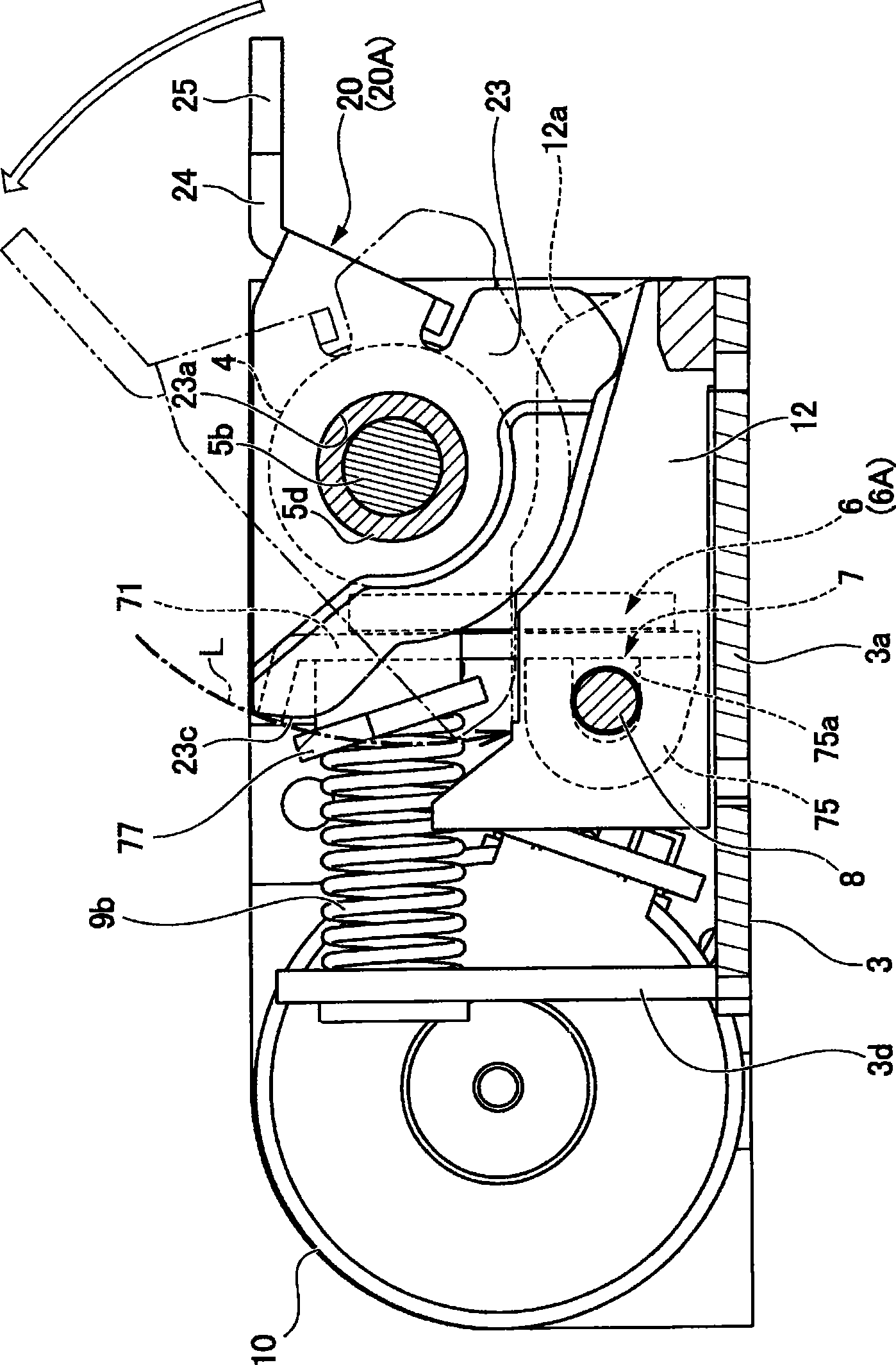

[0034] figure 1 It is a figure which shows the printer mechanism part of the line thermal printer which concerns on embodiment of this invention, (a) is a perspective view seen from the rear side, (b) is a perspective view seen from the front side. and figure 2 It is a schematic sectional view of the printer mechanism.

[0035] The printer mechanism unit 2 of the line thermal printer 1 has a configuration in which each unit is mounted on a printer frame 3 made of a metal plate or the like. The printer frame 3 has a bottom plate portion 3a, left and right side plate portions 3b, 3c, and a rear plate portion 3d. Between the left and right side plate parts 3b, 3c, a platen roller 4 is horizontally erected along the width direction of the printer, and the shaft ends 5a, 5b of the platen shaft 5 protruding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com