Ink jet printing apparatus and print head recovery method

A recovery method, print head technology, applied in printing and other directions, to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

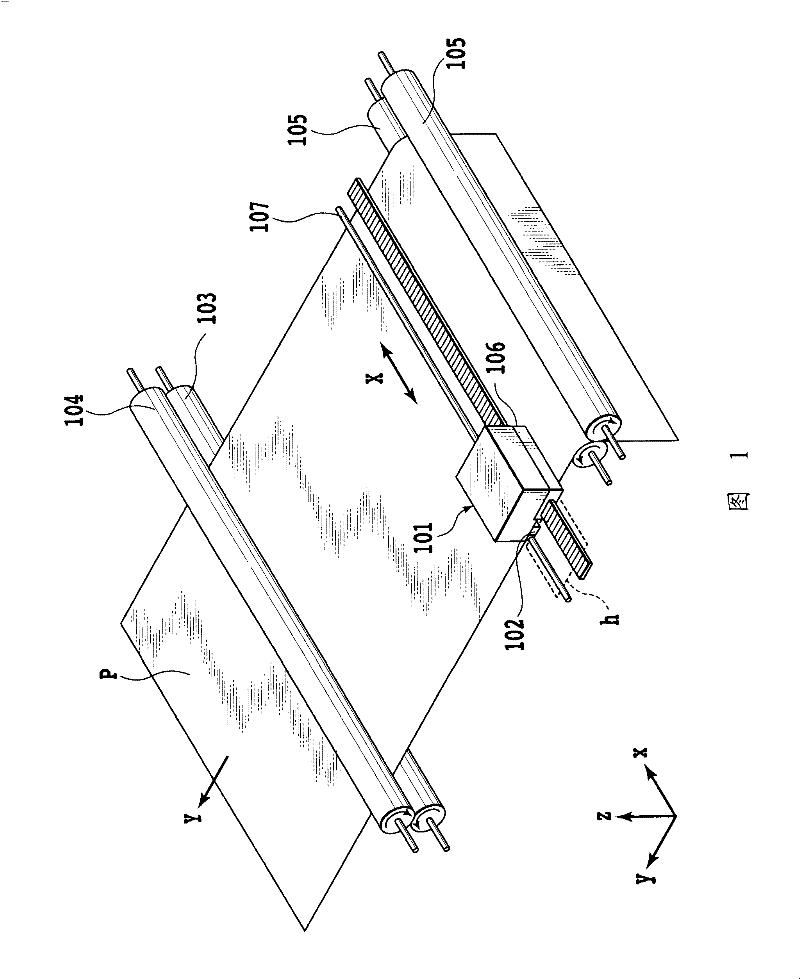

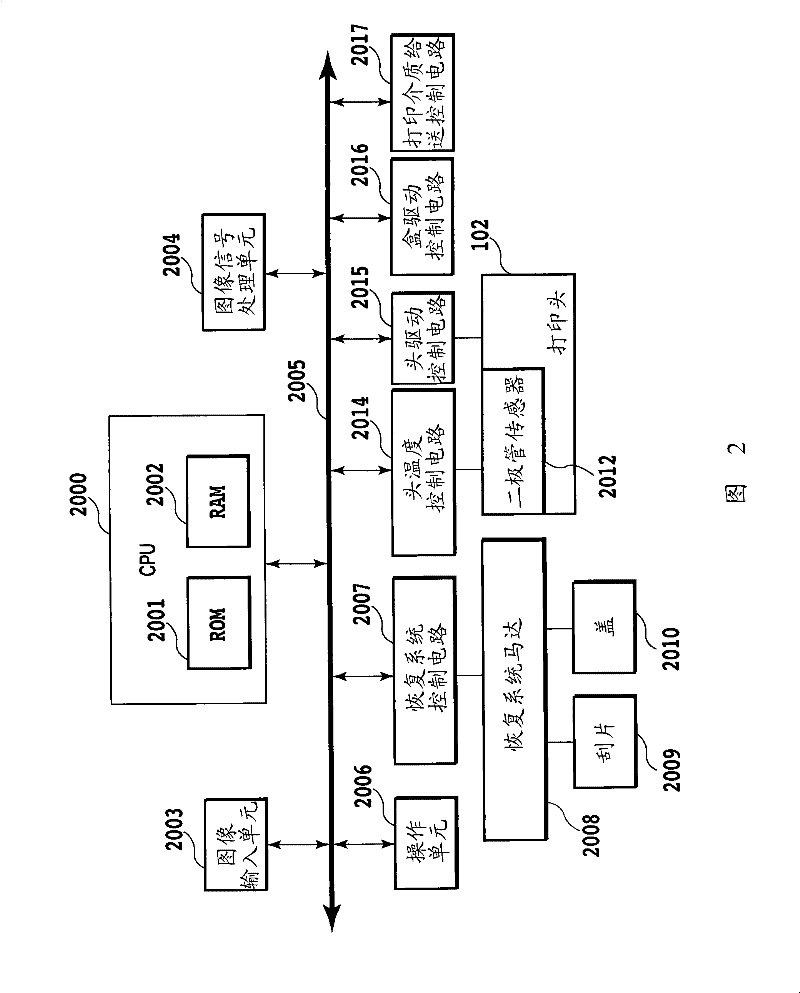

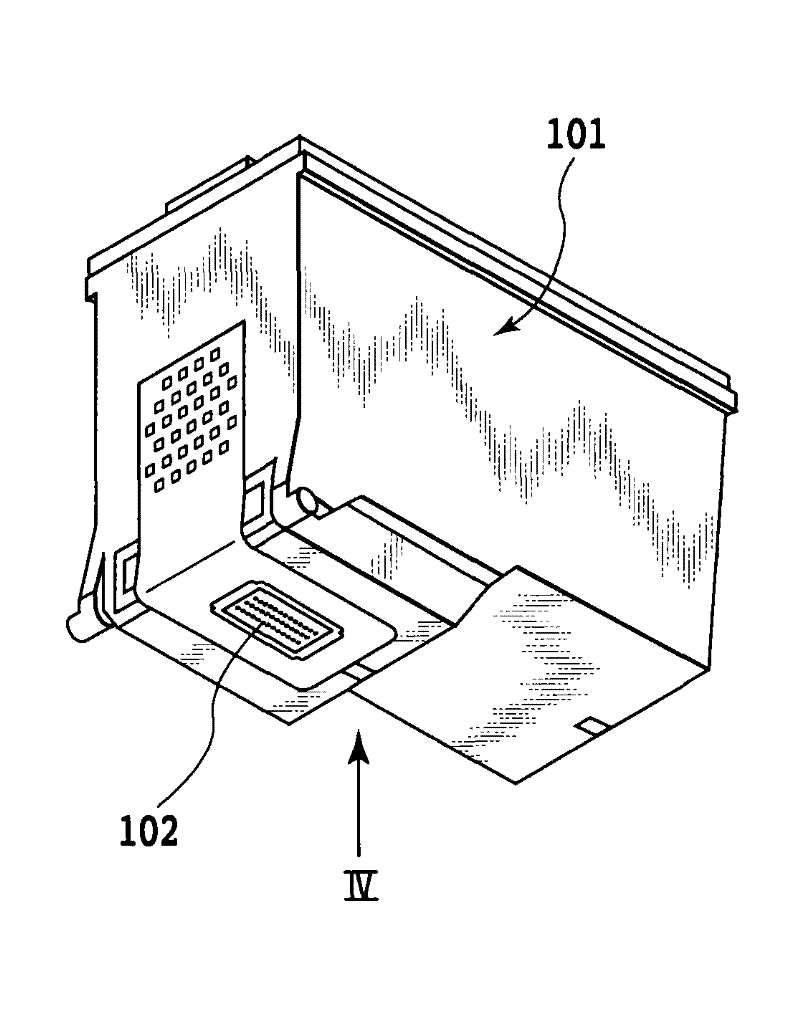

[0043] Figure 1 ~ Figure 13B Shows the first embodiment of the present invention. The first embodiment of the present invention will be explained in the following four separate sections: the mechanical structure of the printing apparatus, the structure of the control system in the printing apparatus, the structure of the head cartridge, and the recovery operation.

[0044] Mechanical structure of printing equipment

[0045] figure 1is a schematic perspective view of a serial inkjet printing device to which the present invention can be applied. This serial type inkjet printing apparatus forms an image on a printing medium P by repeating a printing scanning operation of the inkjet printing head 102 and a feeding operation of the printing medium P. The print scan operation is an operation of causing the print head 102 to discharge ink from its nozzle openings while moving the print head 102 in the main scan direction indicated by an arrow X (main scan). The feeding operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com